Mounting wheel on shaft, Caution – COATS ProRide Wheel Balancer User Manual

Page 18

14 •

Important: Always read and follow instructions.

Wheel Locking

Enable/disable wheel locking in the weight correction

position. Operational only on PL version balancer.

The possible options are:

OFF: disabled

ON: enabled

ALUS: enables wheel locking in position for the ALUS

correction mode only.

Laser

Enable/disable laser for adhesive weight positioning.

Note that offset arm locking will not be enabled when

laser is activated.

Special Functions Screen

Buttons enabled:

Owner Address

This information appears on the screensaver.

Operators Name

Enter up to four different machine user names. Follow

the on-screen instructions to complete the customizing.

Machine Self-test

Self-diagnostic screen is provided for easier trouble-

shooting.

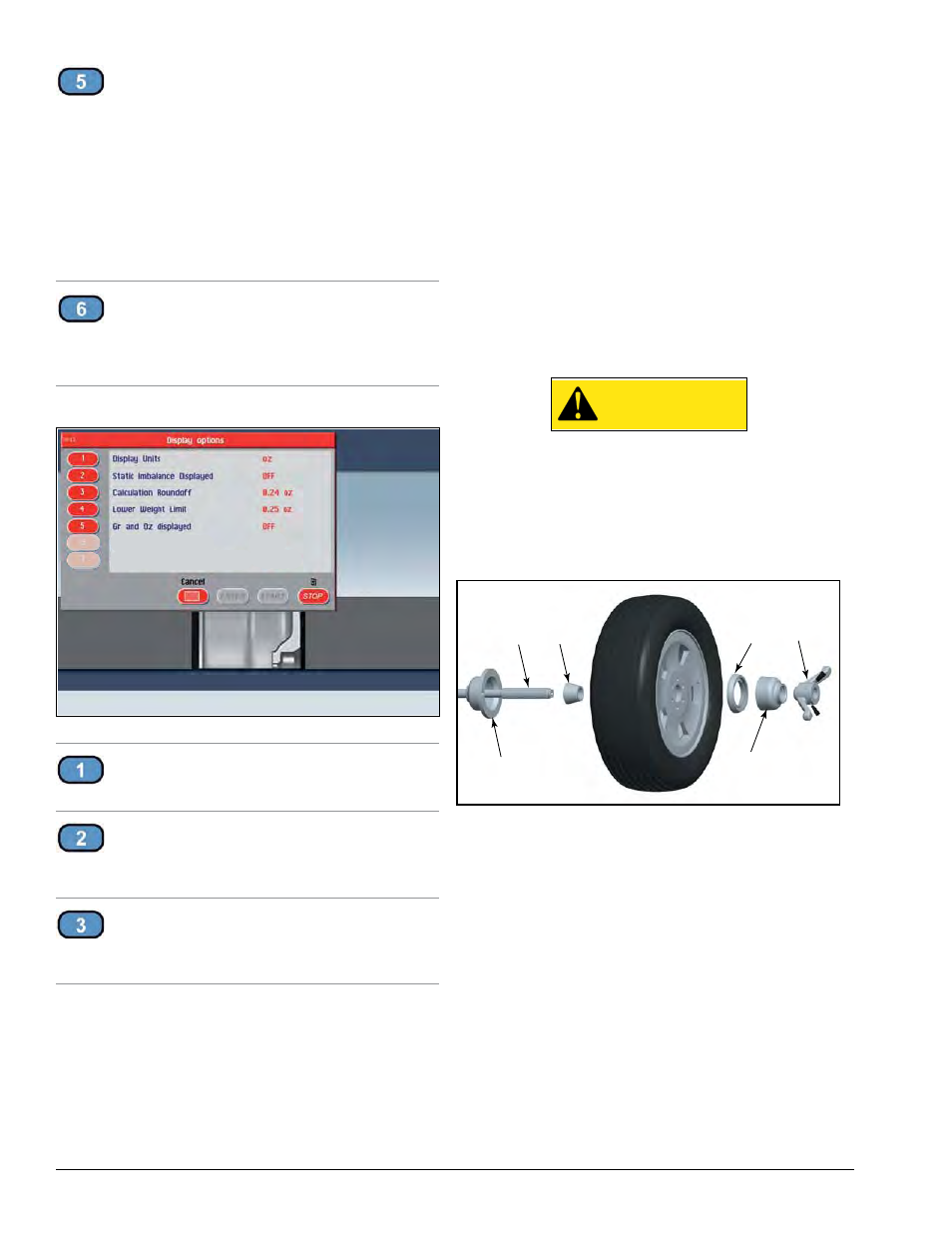

Mounting Wheel On Shaft

Select the most appropriate mounting method for

the wheel you are balancing. Using the proper method

ensures secure mounting and safe balancer operation,

and prevents damage to the wheel.

On most wheels, the inner side of the wheel hub usu-

ally has the most uniform surface for wheel balancing.

Always center the wheel by the most uniform shaped

side of the hub to achieve the most accurate balance.

Regardless of mounting type, on standard units,

always make sure that the wheel is forced firmly against

the shaft faceplate and that the hub nut engages the

threaded shaft for at least four complete turns. To assist

in centering the wheel properly, rotate the wheel and

the shaft while tightening the hub nut.

CAUTION

Failure to tighten the hub nut properly may

result in the wheel dismounting, causing

personal injury and property damage.

Standard Back Cone Mounting

Most original equipment and steel wheels can be

mounted properly using this method. The wheel is

centered on a cone from the inner side of the hub.

Figure 7 - Standard Back Cone Mounting

1.

Select the cone that best fits the center hole in the

wheel. Slide the cone onto the shaft with the large end

towards the faceplate.

2.

Lift wheel onto the shaft and center it on the cone.

3.

Attach the pressure cup to the hub nut and install

the assembly onto the shaft. Tighten securely.

Note: Use a nylon spacer (no mar ring) to protect

custom wheel finishes.

4.

Thread the hub nut onto the shaft, and tighten it

against the wheel. The wheel must be forced firmly

against the faceplate. The hub nut must engage the

threads for at least four full turns.

Note: If the hub nut will not tighten completely, use

the front cone mounting method.

Shaft

Cone

Pressure

Cup

Protective

Ring

Hub Nut

Face Plate