Wheel mounting – COATS 6200HS Truck Wheel Balancer User Manual

Page 23

Operation Guide

17

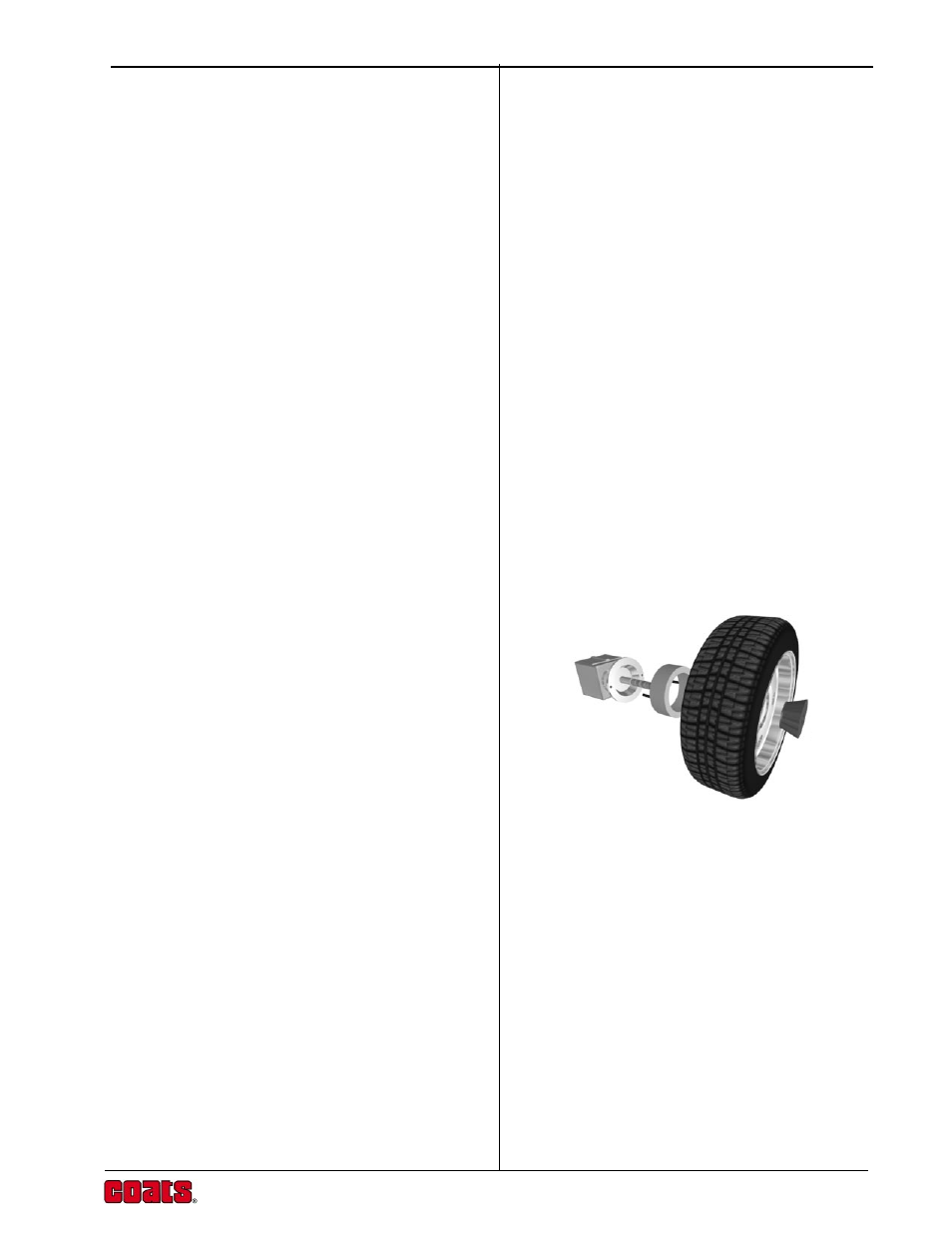

WHEEL MOUNTING

Careful wheel mounting is essential, as the wheel is

balanced relative to how it is mounted on the balancer.

If the wheel is not well centered and sitting squarely

against the balancer flange plate, accurate balance

results will not be achieved.

Most stud-centered wheels have concentric center holes,

which allow fast and easy cone mounting. Adapters

should be used only in problem situations and on some

aftermarket specialty wheels.

The Standard Accessories and Optional Accessories

supplied with your COATS balancer allow the following

wheels mounting methods.

Wheel Mounting Methods (Truck Wheels)

Cone Mounting

Hub piloted wheels must be cone mounted. Hub piloted

wheels can be identified by the lack of stud hole

countersinks.

Install the Spacer Ring / Distance Ring against the back

flange of the balancer. The Ring is required for large and

medium truck cones, and is optional for use with light

truck cone.

Choose a cone that fits best when placed into the wheel

center hole. With the tire on the ground, slide the

balancer so that the spindle extends through the wheel

center hole as shown. Mount the cone on the protruding

spindle and slide into the wheel center hole. Raise or

lower the spindle with the lift handle as needed for

optimum alignment. Thread the Spindle Nut or Hub Nut,

whichever is appropriate, onto the spindle and hand

tighten. Raise the wheel slightly so that it clears the

ground and securely tighten the Spindle or Hub Nut.