Maintenance, 8 a38e work platform, 7 boom rest limit switch – Snorkel A38E-sn006001+ User Manual

Page 40: Tilt sensor

Maintenance

Section

4-8

A38E Work Platform

4.7 Switch Adjustments

(Figure 4-7 & 4-8)

4.7

BOOM REST LIMIT SWITCH

Function: This limit switch is activated when the

Elevating Assembly is fully stowed and

the upper boom is sitting in the boom rest. The Boom

Rest is located on the side of the First Post on the

A38E Work Platform. The high speed drive can only

be operated when this switch is activated. When the

boom leaves the boom rest the Normally Open con-

tacts of the limit switch open and power is cut to the

high speed drive function.

Location: The switch is located on the side of the

First

(see fig 4-8)

Post on the Boom Rest Weldment.

Adjustment:The switch should be activated when the

boom sits in the boom rest. The lever is

adjustable and should be adjusted so that the

switch’s activation/deactivation point occurs just as

Boom 2 leaves the Boom Rest. To adjust the switch

loosen the lever clamping nut and rotate the lever.

Tighten the lever clamping nut. The switch should

periodically be checked for freedom of movement and

be kept clean from dirt and other contaminants that

might affect its free movement.

TILT SENSOR

Function: This limit switch is activated when the

internal sensor in the ‘Tilt Sensor’ is tilted

3

°

or more (factory set at this value). When the Tilt

Sensor activates the elevating and telescope extend

functions will be locked out and an audible warning

alarm will sound. It will activate if the Chassis tilts 3

°

in any direction.

The Tilt Sensor is incorporated in the GP400 control

module.

S

ETTING

T

HE

T

ILT

S

ENSOR

T

O

Z

ERO

If the EZ230 control modual is replaced and/of moved within the

machine for any reason the tilt sensor must be reset for zero°

using the following procedure. Failure to do so could result in serious

injury or death.

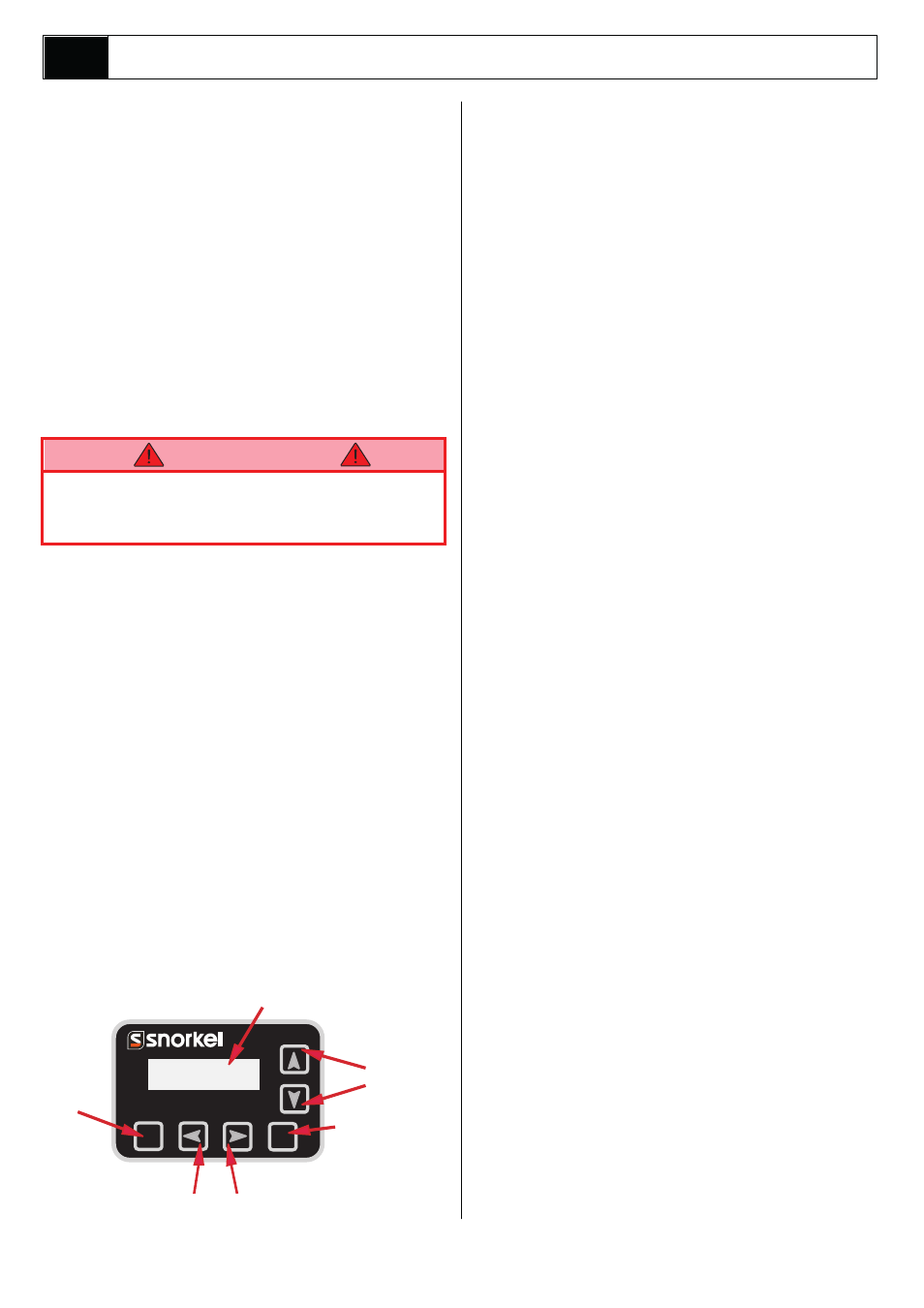

To follow this procedure you need to switch the Ezcal

display in the Upper Control Box into “Calibration mode”.

1. Place the machine on a firm level surface , ≤ 0.25 °

2 Use a Gauge to confirm that the front and rear of the

chassis are level to within +/- 0.25 ° in both directions

3. Switch the machine on, press and hold Esc for 5 seconds

.

s

r

a

e

p

p

A

”

u

n

e

M

t

fi

l

z

E

“

li

t

n

u

4. Scroll to access level.(Enter)

5.

Enter code 2222 for access level 2 .(Enter)

6. Scroll to setups.(Enter)

7. Scroll to tilt setups . (Enter)

8. Calibrate level. (Enter)

9. Enter for yes.

To confirm calibration has worked switch the machine of then

back on again.

10. Scroll to Diagnostics. (Enter)

11. System. (Enter)

12. Scroll to tilt, both readings should be below 0.2 ° if not

repeat from 3.

ESC

ENTER

Esc to leave

Sub-Menu

without saving.

Display

Enter to Save

Entry

Scroll

Left/Right

Change Entry

Up / Down

W A R N I N G