Maintenance – Snorkel A38E-sn006001+ User Manual

Page 45

Maintenance

Section

A38E Work Platform

4.10

Every

500 working hours, or annually

Brushes -

Check the wear, the correct seating,

and the regularity of the working

surface.

Springs -

They should not be burned or

damaged, and they must apply a

constant and equal pressure on the

brushes.

Commutator - The surface must be clean and

regular without grooving or burning.

Every

1000 working hours, or every two years

Bearings-

All the bearings are fitted with a

double shield and lubricated with

high temperature grease.

Check for leaks, vibration and noise.

If necessary replace with bearings

of identical type.

Screws -

Check that all nuts, particularly the

cable nuts and screws are tight.

General -

Check that foreign bodies or dirt

have not entered the motor.

Check that the ventilation holes are

clean and not obstructed.

4.10 Traction Motor Maintenance

-512944-000 ( See 7-21)

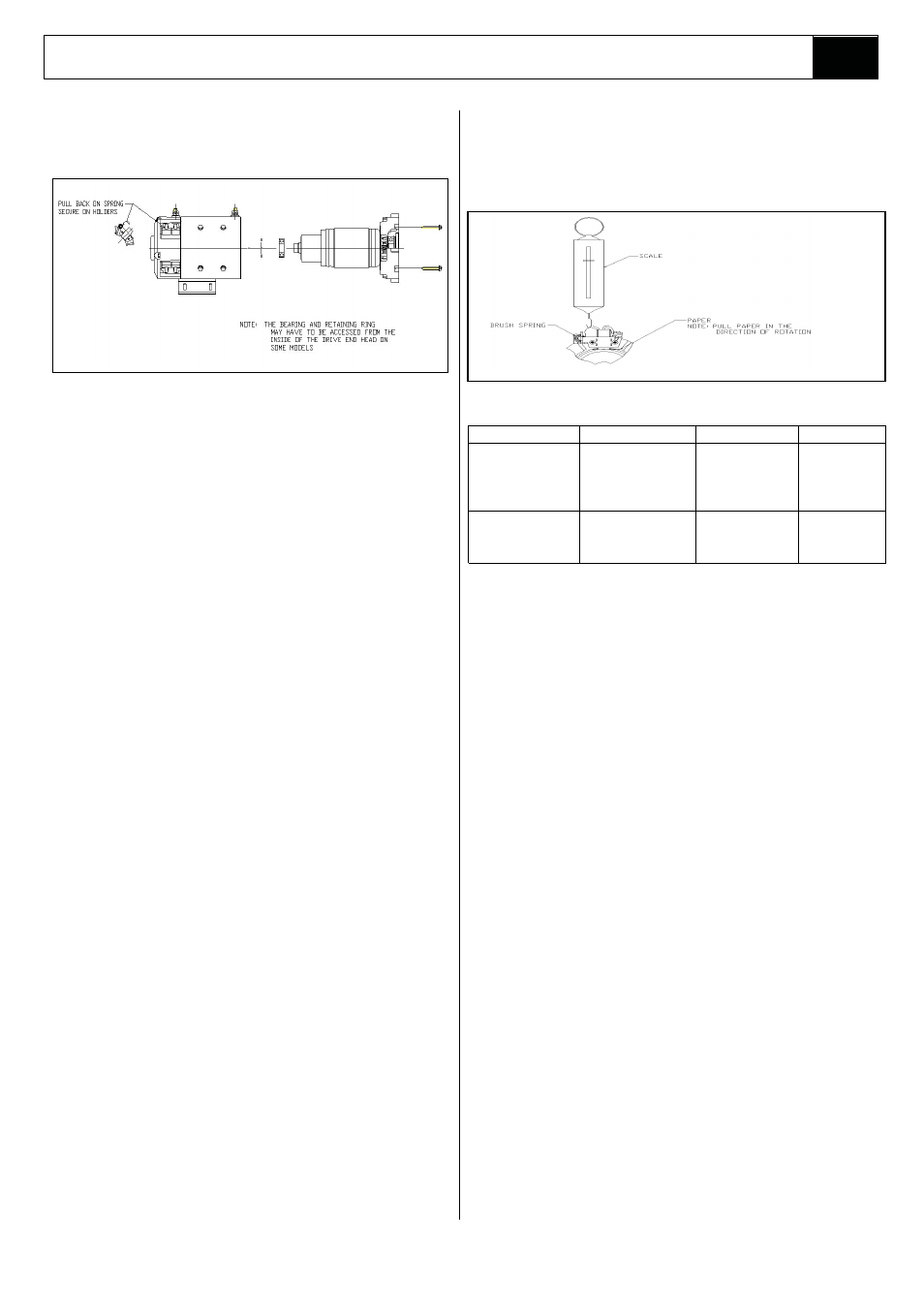

Figure 1. Exploded view of Drive End Locked Motor

1. Pull back the brush springs and latch them on the

holders in the open position (or if the brush box

assembley has no holders, pull the springs out,

pull the brush back and rest the springs on the

side of the brush). See Figure 1. The brushes

should move freely within the holders.

2. Check the brush springs for correct alignment on

the back of the brush. A brush spring that does

not apply equal pressure on the center of the

brush will cause the brush to wear unevenly.

Check for correct clearence and freedom of brush

movement in the holder.

Figure 8.

Brush Tension Testing

Motor Diameter

Ounce

Gram

5.5 inch

New Brush

55

1540

Worn Brush

35

980

6.7 Inch

8.0 inch

9.0 Inch

New Brush

65

1820

Worn Brush

40

1120

Table 2. Brush Tension Values

3. Replace brushes that are worn below their usable

length, show signs of uneven wear or signs of over

heating, such as discoloured brush shunts and

brush springs.

4. Make sure the brush box assembley is tight on the

commutator end head. Replace brush box

assemblies in the commutator end head if they are

physically damaged or brush holders are loose on

on the brush plate.

5. Brushes should always be replaced in complete

sets of four or eight. Use identical replacement

parts; do not substitute brush grades as the

are matched to the motor type and application to

provide the best service. Substituting brushes of

the wrong grade can cause premature

commutator failure and excessive brush wear.

6. Carefully release the brush springs allowing the

brushes to contact the commutator.

Brushes should be checked for proper tention

using the following procedure:

a. Place paper strip between brush face and

commutators. See Figure 8.

b. Hook spring scale as shown.

c. Pull spring scale on a line directly opposite the line of

force exerted. When the paper strip begins to move

freely read the spring tention on the scale.