Maintenance, Removal, Disassembly (refer to figure 4-16) – Snorkel A38E-sn006001+ User Manual

Page 53: Cleaning and inspection, Reassembly/seal replacement

Maintenance

Section

4-21

A38E Work Platform

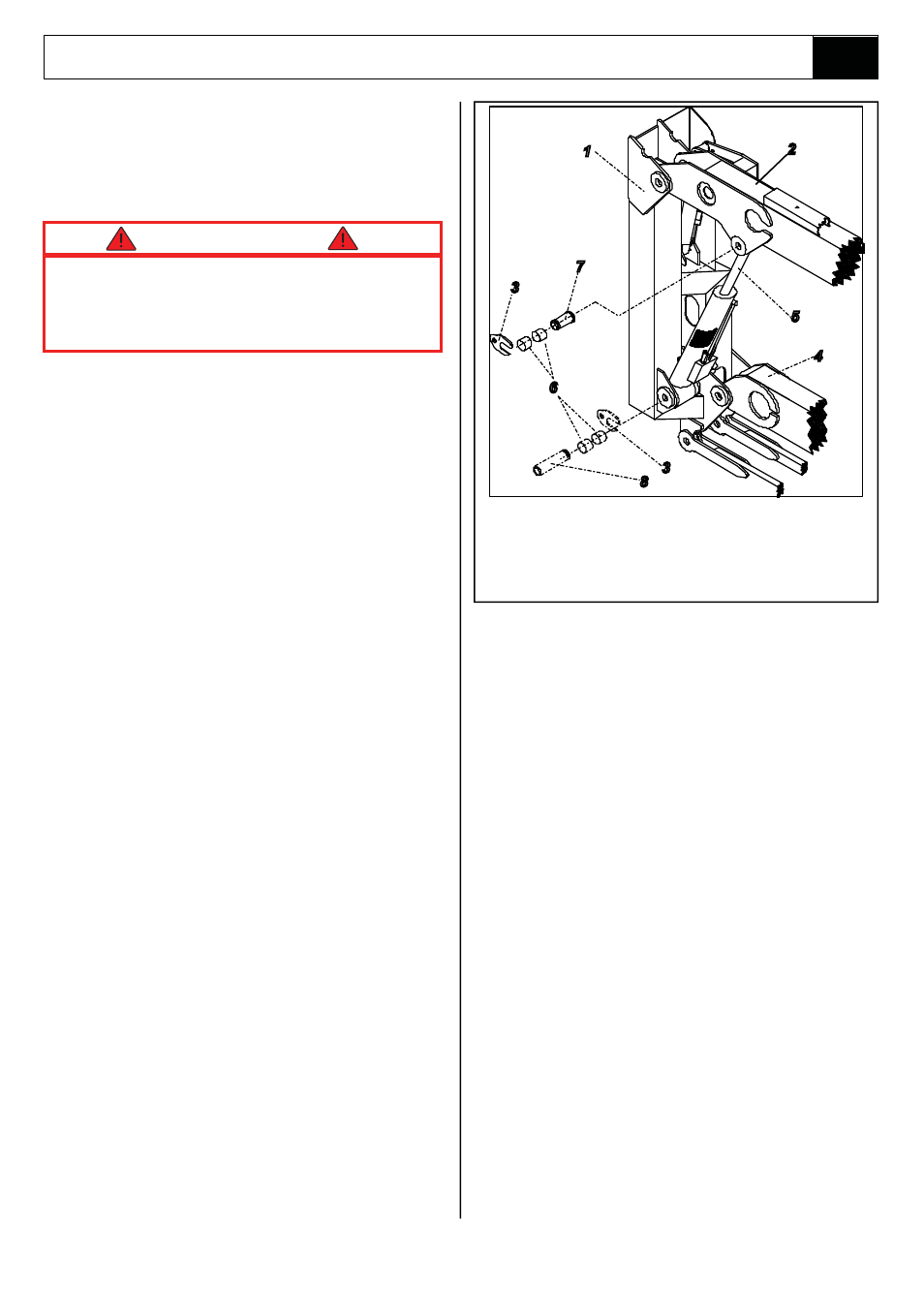

Figure 4-17: Upper Lift Cylinder

1.

Second Post

2.

Upper Boom

3.

Pin Lock Plate

4.

Lower Boom

5.

Upper Lift Cylinder

6.

Bushings

7.

Rod End Pivot Pin

8.

Barrel End Pivot Pin

2

4.15

4.15 Upper Lift Cylinder

(Figure 4-17)

REMOVAL

The Upper Lift Cylinder is heavy, so utilise

appropriate lifting equipment to support the

unit before removing pins.

1.

Ensure that the A38E is on firm level ground,

the Elevating Assembly is completely stowed,

the Keyswitch is to the ‘OFF’ position and the

Emergency Stop Button is pressed.

2.

Provide a suitable container to collect the

hydraulic fluid, then disconnect the hydraulic

hoses. Immediately plug hoses to prevent

foreign material from entering.

3.

Remove securing bolts and the pin lock plates

from the cylinder pins.

4.

Support rod end of cylinder and remove rod end

pivot pin. Let cylinder down to hang freely.

5.

Support the cylinder so that the barrel end

cylinder pin can be removed, then remove the

cylinder from the machine.

6.

Move the cylinder to a prepared work area. It is

important that clean assembly practices are

observed as seals and other hydraulic cylinder

components are highly sensitive to

contamination.

DISASSEMBLY (Refer to Figure 4-16)

1.

Unscrew the headcap and withdraw the rod and

piston assembly from the barrel tube.

2.

Unscrew the piston nut and remove piston and

headcap from the cylinder rod.

3.

Remove the piston static O-ring from the

cylinder rod.

4.

Remove the piston seal from the piston.

5.

Remove the rod seal, rod wiper and static seal

from the headcap.

6.

Care should be taken to save the O-ring and all

other seals for reassembly, if they have been

deemed serviceable following the cleaning and

inspection phase of maintenance.

CLEANING AND INSPECTION

1.

Clean all metal parts in solvent and blow dry

with filtered compressed air.

2.

Check all threaded parts for stripped or

damaged threads.

3.

Check the bearing surfaces inside of the

headcap, outer edge surface of the piston,

inside of the cylinder barrel and the shaft for

signs of scoring, pits, excessive wear or

polishing. Scratches or pits deep enough to

catch a fingernail are unacceptable. Polishing is

a sign of uneven loading and if sufficiently

polished the affected parts should be replaced.

4.

Replace any parts or seals found to be

unserviceable.

REASSEMBLY/SEAL REPLACEMENT

1.

Lubricate and install new rod seal, rod wiper

and static seal on the headcap.

NOTE: Multi-purpose lubricant should be used.

2.

Install a new piston seal on the piston.

3.

Install the headcap on the cylinder from the

piston end.

4.

Install the piston, piston nut and a new piston

static O-ring on the cylinder rod. Screw nut to

1

5

4

6

3

8

7

3

Note: During seal replacement do not use sharp

edged tools to avoid cutting the seals, and allow

at least one hour for the seals to elastically

restore to their original shape before assembly.

CAUTION