Schematics, Hydraulic schematics, Table 6-2: hydraulic schematic legend – Snorkel A38E-sn006001+ User Manual

Page 76

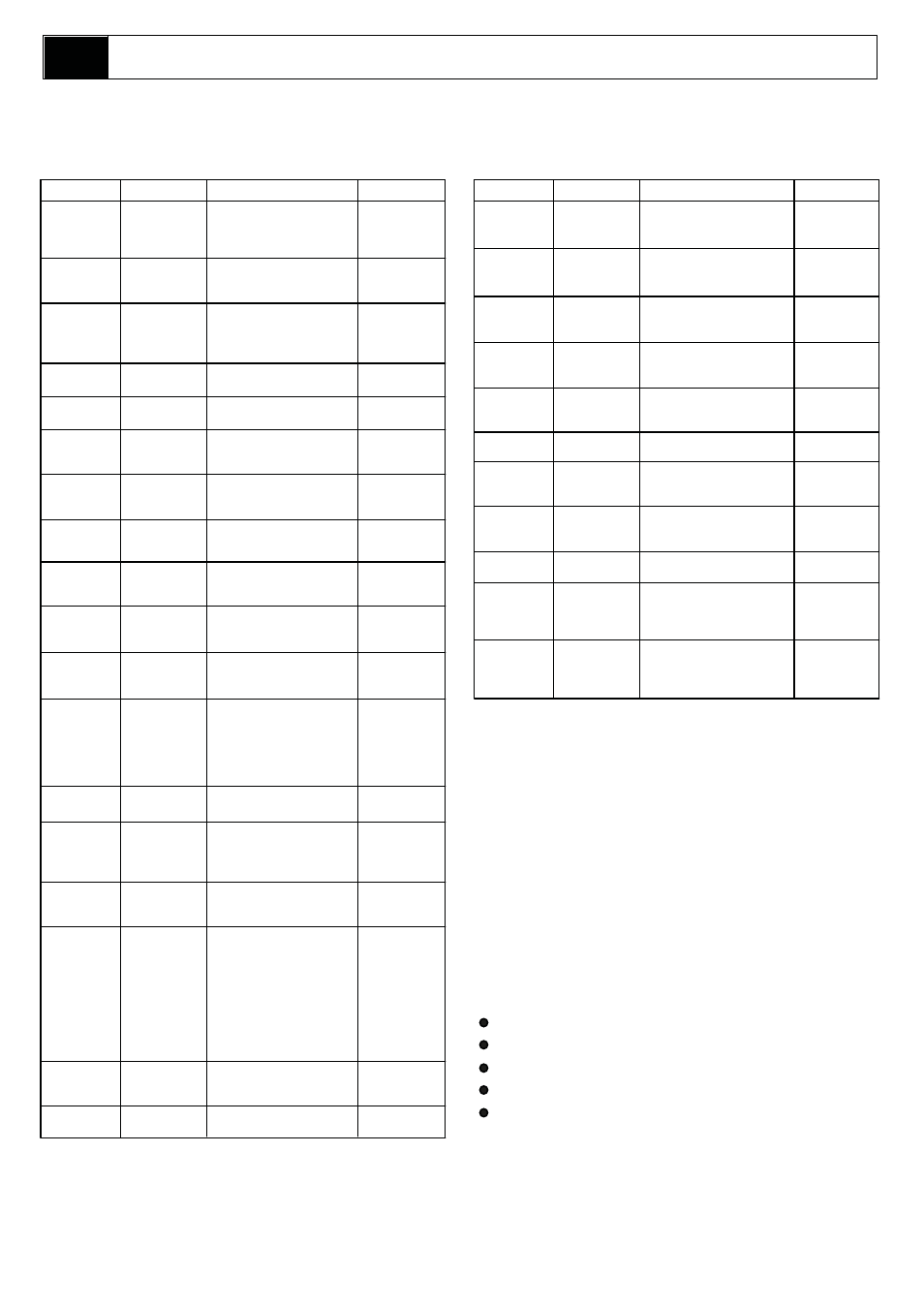

Schematics

Section

6-10

A38E Work Platform

6.2

6.2. Hydraulic Schematics

REFERENCE NAME

FUNCTION

LOCATION

V10 (RV)

Main relief

Sets max system pressure to On main

valve.

175 Bar

manifold block.

V11

Single

Prevents back flow and

On base of

Overcentre

provides a hydraulic lock on upper, lower &

valve.

the cylinder.

tele cylinders.

V12

Emergency

Allows upper and lower boom

On base of

lowering valve. to be manually lowered.

upper and lower

cylinders.

V13

Pilot operated

Holds tele cylinder in position On base of

check valve.

after controls are released

tele cylinder.

V14

Dual

Holds pressure in

On base of

Overcentre

master/slave closed circuit

master cylinder.

valve.

and provides hose burst

protection. (Set 160 Bar).

V15

Dual

Holds pressure in slave

On base of

Overcentre

cylinder and provides host

slave cylinder.

valve.

burst protection.

(Set 120 Bar).

Table 6-2: Hydraulic Schematic Legend

REFERENCE NAME

FUNCTION

LOCATION

BRK

Brake.

Spring applied - hydraulically

On front end of

released brakes to stop

wheel drive

rotation of drive wheels.

motors on

(Set at 100 Bar).

chassis.

CLRV

Cross-line

To limit the max. operating

On main

relief valve.

pressure of the slew motor.

manifold block.

(Set at 50 Bar).

CV

Check Valve.

To prevent oil pressure in the On main

brake line from being lost

manifold block.

through the main pressure

line.

CYL1

Lower boom lift Provides the force to lift the

Foward of first

cylinder.

lower boom - Boom1.

post

CYL2

Upper boom lift Provide the force to lift the

Behind second

cylinder.

upper boom - Boom2.

post

CYL3

Tlelscopic

Provides the force to

Inside Boom2

cylinder.

push/pull the tele-boom

& Tele boom.

- Boom3.

CYL4

Steering

Provides the force to

Inside front of

cylinder.

push/pull the steering torque

chassis.

arms.

CYL5

Master levelling Provides the pressure to the

Behind the

cylinder.

slave cylinder for cage

second post

levelling.

CYL6

Slave levelling Provides the force to level

Close to cage

cylinder.

the cage up/down.

pivot at inner

Tele boom.

FL1

Return line

Continuously filters hydraulic On top of the

filter.

return oil.

hydraulic

(10 Micron)

reservoir.

HP

Handpump.

Used for retraction of tele

On side of

boom in the case of power

manifold block.

failure. Delivers 15cc/stroke.

MMB

Main manifold

Contains the directional

On hydraulic

block.

control valves and relief

reservoir in

valves that distribute oil to

chassis.

the various functions and

control the operating

pressures.

MOT1

Slew Motor.

Drives slew bearings drive

Connected to

pinion.

drive pinion.

MP

Motor/Pump

Gear pump close coupled to

On chassis.

set.

D.C electric motor. Provides

pressurised oil flow for all

hydraulic functions.

V1

Brake oil

This valve is energised to

On main

supply valve.

allow oil into the brake

manifold block

release chamber.

V2

Brake valve.

When energised this valve

On main

prevents the pressurised

manifold block.

brake oil from venting back

to tank. When the machine is

stationary this valve

de-energises and the brake

oil vents to tank and the

brake springs apply

themselves and keep the

machine stationary.

V3

Pressure

Prevents pressures in

On main

reduction valve. excess of 100 Bar entering

manifold block.

the brake chambers.

V4

Slew Directional Send oil to the left or right

On main

Control Valve.

side of the slew motor.

manifold block.

V5

Steer

Send oil to the annular or full- On main

Directional

bore side of the steering

manifold block.

Control Valve.

cylinder.

V6

Tele

Send oil to the annular or full- On main

Directional

bore side of the telescopic

manifold block.

Control Valve.

cylinder.

V7

Boom2

Send oil to the annular or full- On main

Directional

bore side of the Boom2

manifold block.

Control Valve.

cylinder.

V8

Boom1

Send oil to the annular or full- On main

Directional

bore side of the Boom1

manifold block.

Control Valve.

cylinder.

V9

Levelling

Send oil to the annular or full- On main

Directional

bore side of the levelling

manifold block.

Control Valve.

cylinders.

Notes:

1.

All of the Overcentre Valves represented within

this schematic have a 5:1 Pilot Ratio.

2.

The P/O Check Valve represented has a 3:1

Pilot Ratio.

3.

The maximum flow rate of the Pump/Motor Unit

is limited to 15 L/min @ 100% speed. Although

it should be noted that the actual flow rate will

depend on the applied load and the D.C. Motor

speed.

4.

The maximum ‘Return’ flow rates for each of

the functions are restricted to the following

values;

Slew...

4 L/min

Boom1...

8 L/min

Boom2...

5 L/min

Tele...

5 L/min

Steering...

6 L/min.