Maintenance, 6 maintenance on elevating assembly (figure 4-6) – Snorkel A38E-sn006001+ User Manual

Page 39

Maintenance

Section

4-7

A38E Work Platform

4.6

4.6 Maintenance on Elevating

Assembly (Figure 4-6)

The only time the Elevating Assembly needs to be

elevated is to allow service work to be carried out on

the lower parts of the Elevating Assembly, the Lower

Lift Cylinder or the Slewing mechanisms.

All other work (Bearings, Cylinders, Booms & Tension

Bars) can and must be performed with the Elevating

Assembly in the stowed position.

BEFORE entering Elevating Assembly, to

perform maintenance on the Work Platform

while elevated, ensure that Elevating

Assembly is properly supported by suitable

cranage of adequate capacity.

(Recommended 1 tonne capacity crane and

sling.)

INSTALLATION OF ELEVATING

ASSEMBLY SUPPORT

1. Park the work platform on firm level ground.

2. Verify Platform Emergency Stop Switch is ON.

3. Hold the Chassis/Platform Selector Switch on the

Lower Control Box to the ‘Chassis’ position.

4. Select Lower Control Boom 1 Switch and

elevate until the lower boom is slightly above

horizontal.

5. Place a sling of 1 Tonne load capacity at the end of

the lower boom and second post. Ensure sling is

secured so that it will not slip up along the boom.

6. Gradually lower the platform until

Lower Boom is supported by the sling.

REMOVAL OF ELEVATING

ASSEMBLY SUPPORT

1. Select Lower Control Boom 1 Switch

and gradually raise the platform until the

sling can be removed.

2. Remove the sling.

3. Completely lower platform.

4. Turn Key Switch to “OFF”

SLEW CROSS-LINE RELIEF VALVES

1.

Repeat steps 1-3 as outlined above

2.

Loosen Locknuts on both cross-line relief

valves and turn adjusting screws anticlockwise

two full turns.

3.

Operate slew function from lower controls and

rotate the Elevating Assembly until the slew

stop prevents further rotation.

4.

Slowly turn the cross-line relief valve adjusting

screw clockwise using a 4 mm Allen key until

the pressure gauge reads 50 Bar (725 p.s.i.)

pressure.

5.

Now operate the slew function in the opposite

direction through approximately 360

o

until the

Slew Stop prevents further rotation.

6.

Slowly turn the remaining cross-line relief valve

adjusting screw clockwise until the pressure

gauge reads 50 Bar (725 p.s.i.) pressure.

7.

Tighten the locknuts on both cross-line relief

valves while holding the adjusting screws in

position.

Figure 4-5: Setting Cross-Line Relief

Pressures

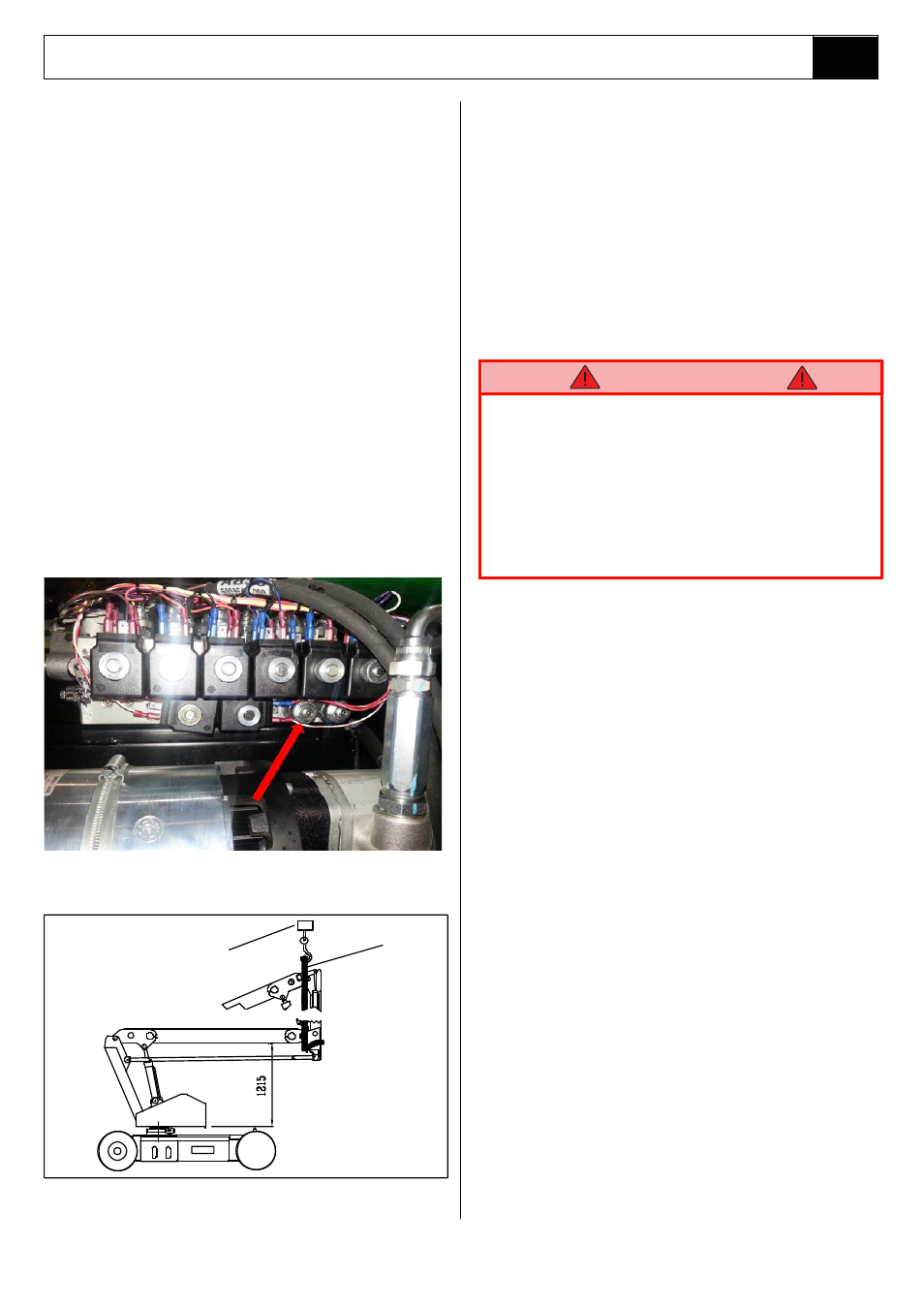

Figure 4-6: Supporting Elevating Assy.

1 Tonne Capacity

Crane/Winch

Sling

W A R N I N G