Maintenance, 22 a38e work platform, Removal – Snorkel A38E-sn006001+ User Manual

Page 54: Disassembly (refer to figure 4-16), Installation

Maintenance

Section

4-22

A38E Work Platform

4.16 Telescopic Cylinder

(Figure 4-18)

REMOVAL

1.

Ensure that the A38E is on firm level ground,

the Elevating Assembly is completely stowed,

the Keyswitch is to the ‘OFF’ position and the

Emergency Stop Button is pressed.

2.

From Chassis Controls extend the Telescope

until the Rod End Pin is just visible. This will

leave a small amount of clearance between the

ground and the Telescopic Boom.

3.

Support the Telescopic Boom & Platform

Assembly to avoid any damage while removing

the Telescopic Cylinder.

4.

Provide a suitable container to collect the

hydraulic fluid, then disconnect the hydraulic

hoses. Immediately plug hoses to prevent

foreign material from entering.

5.

Remove securing bolts and pin lock plates from

the barrel end cylinder pin.

6.

Remove the Telescopic Cylinder rod end circlip

and then push the rod end pin out.

7.

Support the cylinder so that the barrel end

cylinder pin can be removed, then remove the

cylinder from the machine. This is done by

pulling the cylinder forward through the gap

provided in Boom 2 at the 2

nd

post end.

8.

Move the cylinder to a prepared work area. It is

important that clean assembly practices are

observed. Seals and other cylinder components

are highly sensitive to contamination.

DISASSEMBLY (Refer to Figure 4-16)

1.

Unscrew the headcap and withdraw the rod and

piston assembly from the barrel tube.

2.

Unscrew the piston nut and remove piston and

headcap from the cylinder rod.

3.

Remove the piston static O-ring from the

cylinder rod.

4.

Remove the piston seal from the piston.

5.

Remove the rod seal, rod wiper and static seal

from the headcap.

6.

Care should be taken to save the O-ring and all

other seals for reassembly, if they have been

deemed serviceable following the cleaning and

inspection phase of maintenance.

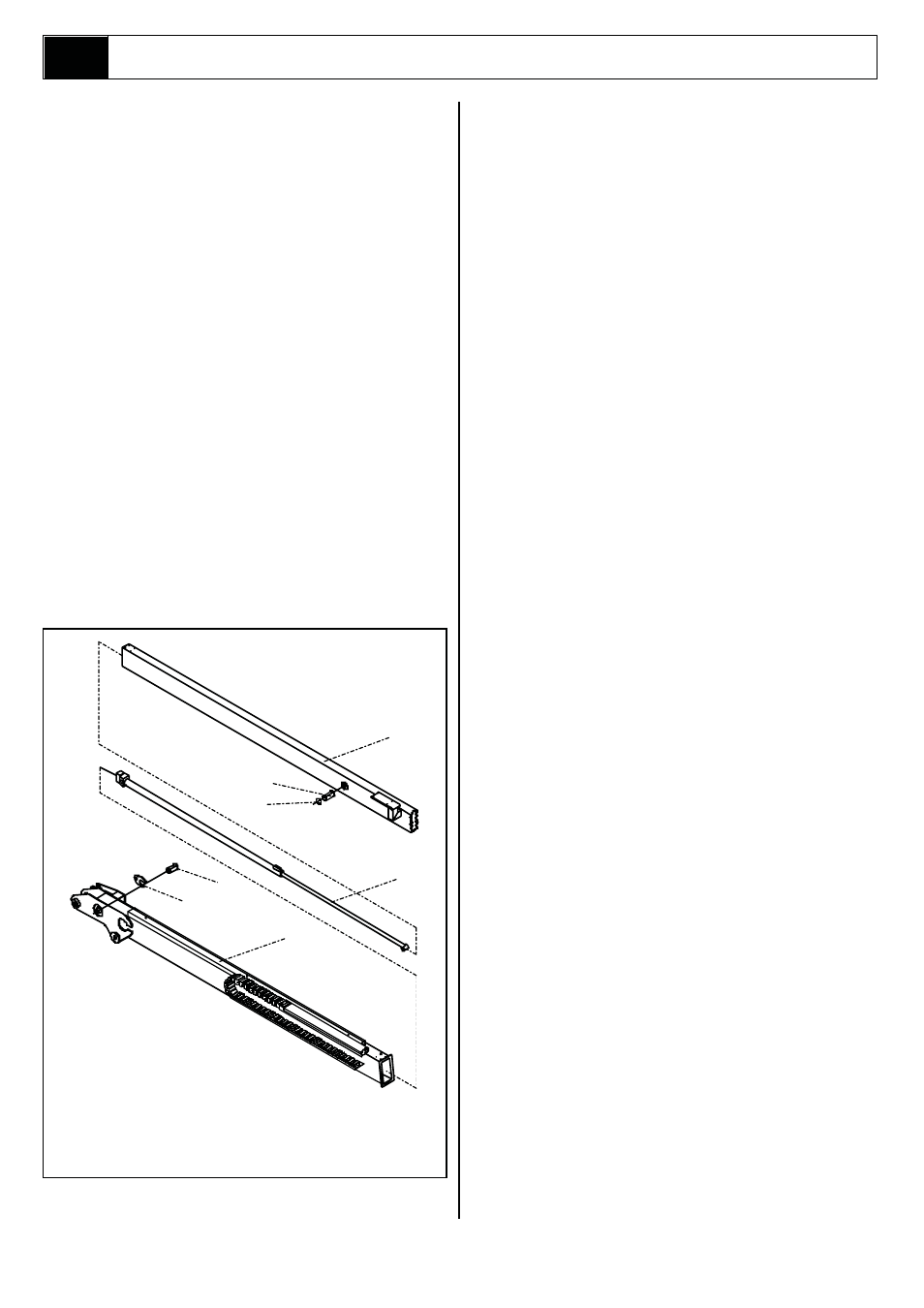

4.16

Figure 4-18: Telescopic Cylinder

end of thread and secure with circlip.

5.

Lubricate the piston seal and install the piston

and rod assembly in the barrel tube.

6.

Thread headcap onto barrel tube and hand

tighten, then turn 1/4 turn further.

7.

Install the upper cylinder Overcentre valve.

INSTALLATION

NOTE: Before installing Lift Cylinder check cylinder

pins and bearings for wear and replace if necessary.

1.

Install barrel end bearing (if removed)

2.

Lift the barrel end of the cylinder into place and

push the cylinder pin in.

NOTE: Take care in aligning the holes so that the pin

can be pushed in by hand. Bearings will be damaged

if holes are not properly aligned and the pin is forced.

3.

Align pin lock plate on cylinder pin with hole in

the mast and push the cylinder pin completely

in. Fix pin lock plate with bolt.

4.

Install rod end bearings (if removed).

5.

Lift rod end of cylinder into place and insert pin.

Install pin lock plate. Fix pin lock plate with bolt.

6.

Test with weight at rated platform load to check

system operation.

1.

Upper Boom

2.

Pin Lock Plate

3.

Circlip

4.

Telescopic Cylinder

5.

Barrel End Pivot Pin

6.

Rod End Pivot Pin

7.

Telescopic Boom

7

4

3

6

1

2

5