Snorkel TB60 2001 User Manual

Page 57

10. DAILY INSPECTION & MAINTENANCE

10 - 5

P/N 0082168

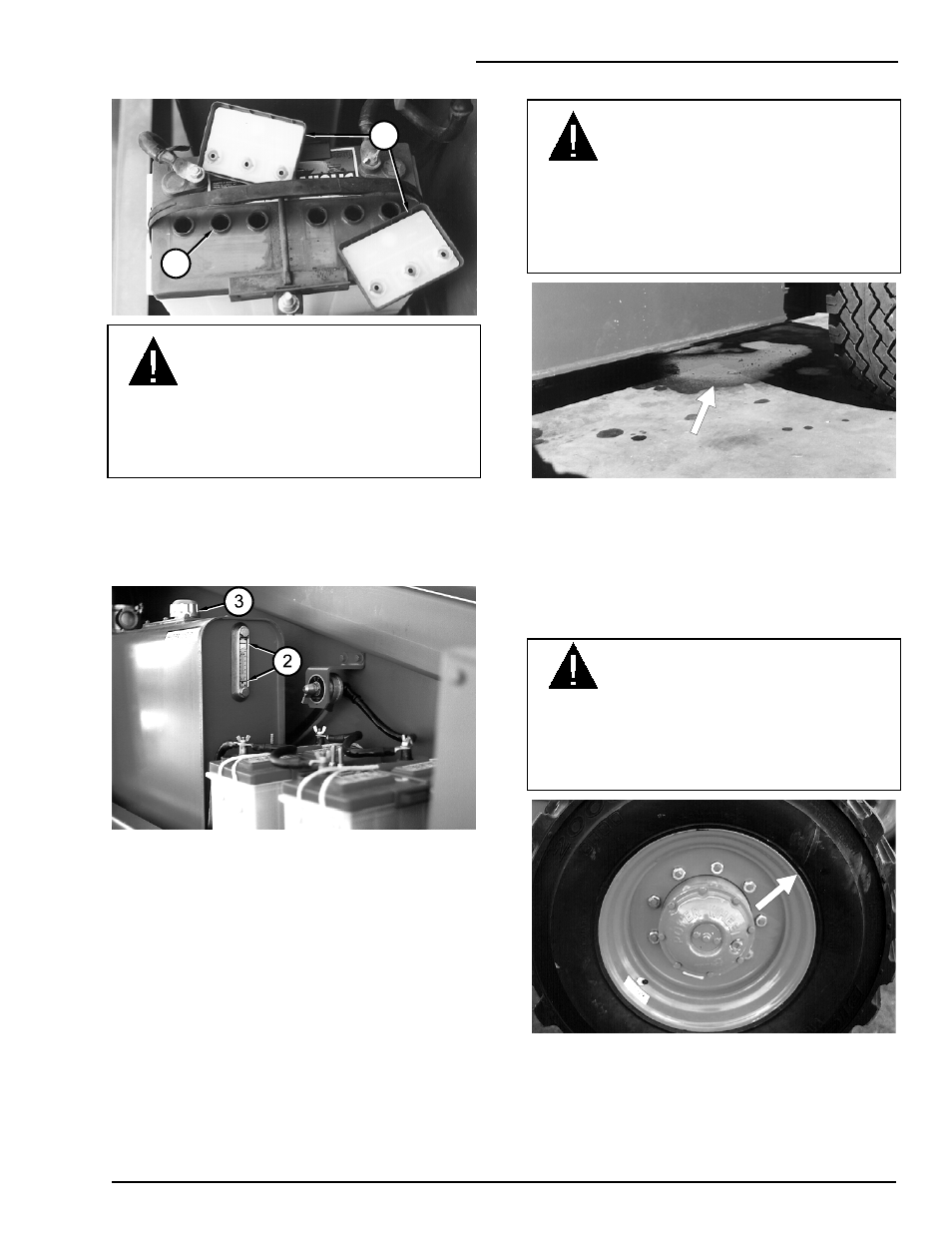

8. Battery fluid level

2

1

D A N G E R

Batteries emit hydrogen and oxygen,

elements that can combine explosively. Do

not smoke or permit open flames or sparks

when checking batteries.

Remove the caps (1) and visually check to see

that the battery fluid is in contact with the

bottom of the filler neck (2) inside each hole.

9. Hydraulic oil

To check the hydraulic oil level:

Completely lower and completely retract the

booms.

The hydraulic oil temperature (1) should be

less than 200°F (93°C).

The hydraulic oil level should be between

the two marks (2) on the sight-glass gauge.

If necessary, add hydraulic oil at the filler cap

(3). See the “SPECIFICATIONS” chapter for

type and grade of hydraulic oil.

10. Hydraulic oil leaks

D A N G E R

Leaking hydraulic oil can cause burns, fires,

falls (slipping), cuts, and puncture wounds

(if under high pressure). Have a qualified

trained maintenance person repair all

hydraulic oil leaks before you operate a TB 60.

Hydraulic oil leaks are easily visible and can

show up anyplace. Visually inspect the entire

machine for hydraulic oil. Check the ground

under the machine for leaked oil. Check the

platform end of each boom - oil can run down

the inside of a boom and drip out the end.

11. Tires

D A N G E R

Death or serious injury can result if a TB 60

tips over. An air-filled tire that has an air leak

or blow-out is a tip over hazard. Do not raise

the platform if any tire has an air leak or is in

such condition that a blow-out could occur.

TB 60 tires are air-filled. Air-filled tires should

be visually checked several times a day to see

that they are properly inflated. Air-filled tires

should be checked very carefully for imbedded

material, cuts, punctures, abraded areas, or

excessive wear.