Cam sensor – AEM 30-6905 Universal Programmable EMS-4 User Manual

Page 33

Page 33 of 279 EMS-4 Install and Tuning Guide_Rev 1.6

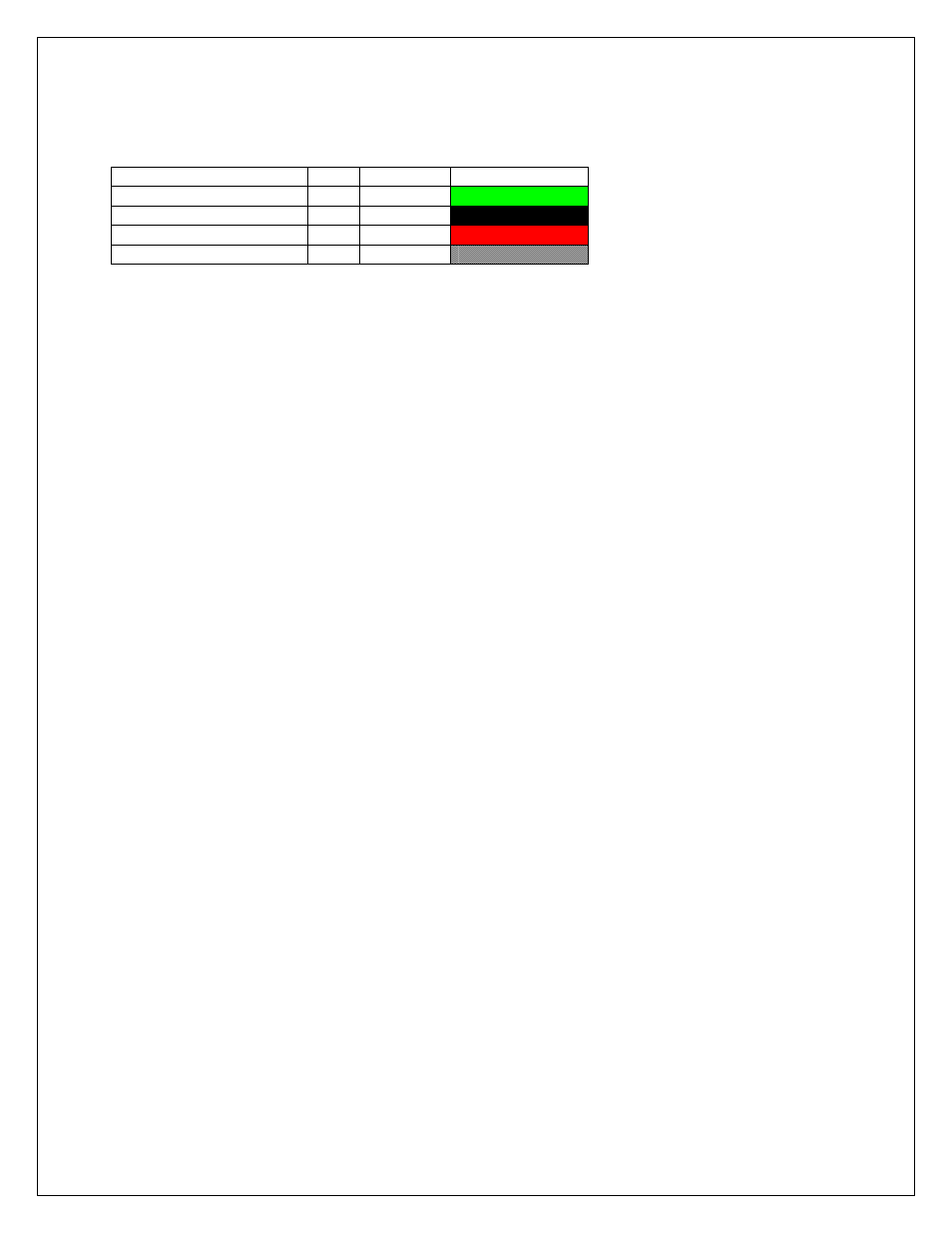

Harness Connections

Crank Sensor Harness Connections

Crank Sensor Ground

28

White

Crank Sensor Mag Input

28

Green

Crank Sensor Hall input

24

Black

+12 volts

24

Red

Cable Shield

---

Crank Sensor Mag Input, Green

– Connect to VR (+) signal (rising edge zero cross). Not used

for Hall sensor configurations.

Crank Sensor Hall input, Black

– Connect to Hall sensor signal. Not used for VR sensor

configurations.

+12 volts, Red

– Connect to Hall sensor reference voltage. Not used for VR sensor

configurations.

Insulate if not using (hot at key-on).

Crank Sensor Ground, White

– Connect to Crank sensor VR (-) or Hall sensor signal ground

Cam Sensor

Cam Sensor Basics

The cam sensor is used to calculate engine position. It is necessary for sequential fuel

calculations. It senses a toothed wheel (reluctor wheel, reluctor ring, etc.) and converts this

pattern into a voltage/frequency signal that the EMS uses for basic calculations. Combined with

the crank position sensor, it is one of the most important inputs to the system. There are two

basic types of cam sensors, variable reluctance (VR or “mag”) and hall-effect.

All VR Cam Sensor inputs to the EMS-4 must be connected such that the rising edge of the raw

sensor signal is the consistent zero crossing edge as shown in the examples above. Failure to

do this could result in misfires or ignition timing inaccuracies. Verify data with an oscilloscope or

contact your sensor manufacturer to verify polarity. The crank inputs to the EMS-4 are

contained within a black shielded cable assembly as shown below. Refer to the EMS-4

System Diagram for more information.