Bryant 312AAV User Manual

Page 9

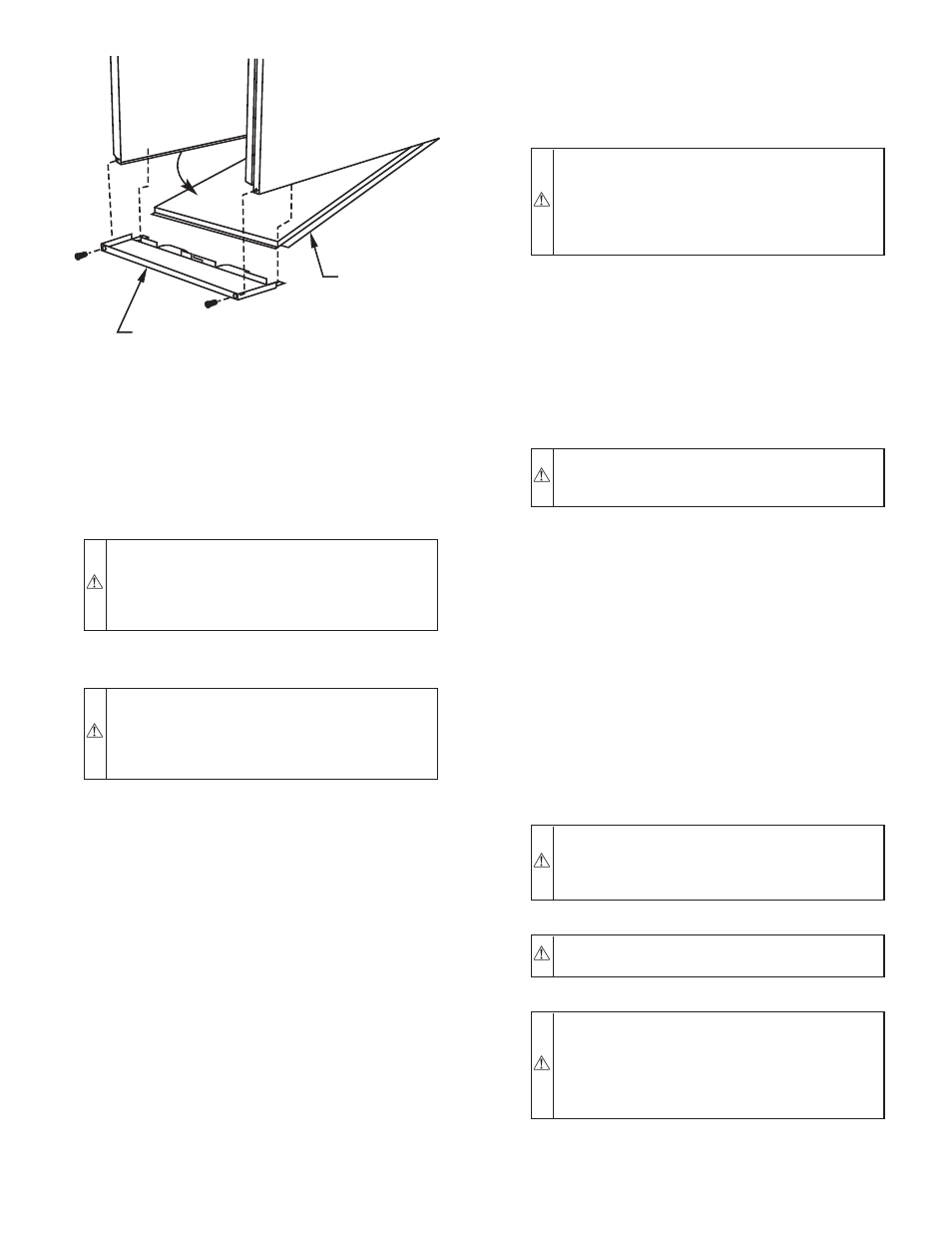

If Coil Assembly Part No. CD5 or CK5 or Coil Box Part No.

KCAKC is used, install as shown in Fig. 13.

NOTE: Remove the furnace perforated supply-air duct flanges

when they interfere with mating flanges on the coil on downflow

subbase. To remove the supply-air duct flange, use wide duct

pliers or duct flange tool to bend flange back and forth until it

breaks off. Be careful of sharp edges. (See Fig. 14.)

WARNING: Do not bend duct flanges inward. This will

affect airflow across heat exchangers and may cause limit

cycling or premature heat exchanger failure. Remove

duct flange completely or bend it inward a minimum of

210° as shown in Fig. 14.

IV. HORIZONTAL ATTIC INSTALLATION

WARNING: Do not install the furnace on its back;

safety control operation will be adversely affected. Never

connect return-air ducts to the sides or back of the

furnace. Failure to follow this warning could result in fire,

personal injury, or death.

The furnace can be installed horizontally on either the left-hand

(LH) or right-hand (RH) side. A typical attic installation is shown

in Fig. 17.

A. Construct a Working Platform

Construct working platform on location where all required furnace

clearances are met. (See Fig. 2 and 17.)

B. Install Furnace

1. Position furnace in desired location.

2. Connect gas supply pipe. See Fig. 17 for typical piping

entry.

3. Connect supply- and return-air ducts with filter media

cabinet per Step 6.

4. Install 24- X 24-in. sheet metal shield on platform in front

of louvered control panel as shown in Fig. 17.

V. INSTALLATION IN HORIZONTAL CRAWLSPACE AP-

PLICATIONS

These furnaces can be installed horizontally in either horizontal

left or right discharge position. In a crawlspace, furnace can either

be hung from floor joist or installed on suitable blocks or pad. (See

Fig. 16). Furnace can be suspended from each corner by hanger

bolts and angle iron supports. (See Fig. 15.) Cut hanger bolts (4

each 3/8-in. all-thread rod) to desired length. Use 1 X 3/8-in. flat

washers, 3/8-in. lockwashers, and 3/8-in. nuts on hanger rods as

shown in Fig. 15.

CAUTION: The entire length of the furnace MUST be

supported when furnace is used in a horizontal position.

When suspended, bottom brace supports sides and center

blower shelf. When unit is supported from the ground,

blocks or pad should support sides and center blower

shelf area.

VI. MEDIA CABINET (PN 325887–701) AND FILTER AR-

RANGEMENT

Center media cabinet on furnace return-air inlet. If flush fit

required with media cabinet to back of furnace casing, a field

supplied patch plate is required to seal gap at front edge of furnace

and media cabinet. Insert filter (supplied with furnace) into media

cabinet.

WARNING: Never operate a furnace without a filter or

with filter access door removed. Failure to follow this

warning could result in fire, personal injury, or death.

VII. GAS PIPING

Gas piping must be installed in accordance with national and local

codes. Refer to current edition of NFGC in the U.S.

Canadian installations must be made in accordance with NSCNG-

PIC and all authorities having jurisdiction.

Gas supply line should be a separate line running directly from

meter to furnace, if possible.

Refer to Table 5 for recommended gas pipe sizing. Risers must be

used to connect to furnace and to meter. Support all gas piping

with appropriate straps, hangers, etc. Use a minimum of 1 hanger

every 6 ft. Joint compound (pipe dope) should be applied sparingly

and only to male threads of joints. Pipe dope must be resistant to

the action of propane gas.

CAUTION: If a flexible connector is required or al-

lowed by the authority having jurisdiction, black iron

pipe shall be installed at the gas valve and extend a

minimum of 2 in. outside the furnace casing.

CAUTION: Connect gas pipe to furnace using a backup

wrench to avoid damaging gas controls.

WARNING: Never purge a gas line into a combustion

chamber. Never use matches, candles, flame, or other

sources of ignition for purpose of checking leakage. Use

a soap-and-water solution to check for leakage. A failure

to follow this warning could result in fire, explosion,

personal injury, or death.

Fig. 10–Removing Bottom Closure Panel

A93047

BOTTOM

CLOSURE

PANEL

FRONT FILLER

PANEL

—9—