Bryant 312AAV User Manual

Page 6

other flow control must prevent chilled air from entering the

furnace. If the dampers are manually operated, they must be

equipped with means to prevent operation of either unit unless the

damper is in the full-heat or full-cool position.

AIR FOR COMBUSTION AND VENTILATION

Provisions for adequate combustion and ventilation air must be

provided in accordance with Section 5.3 of the NFGC, Air for

Combustion and Ventilation, or applicable provisions of the local

building codes.

Canadian installations must be installed in accordance with NSC-

NGPIC Part 7 and all authorities having jurisdiction.

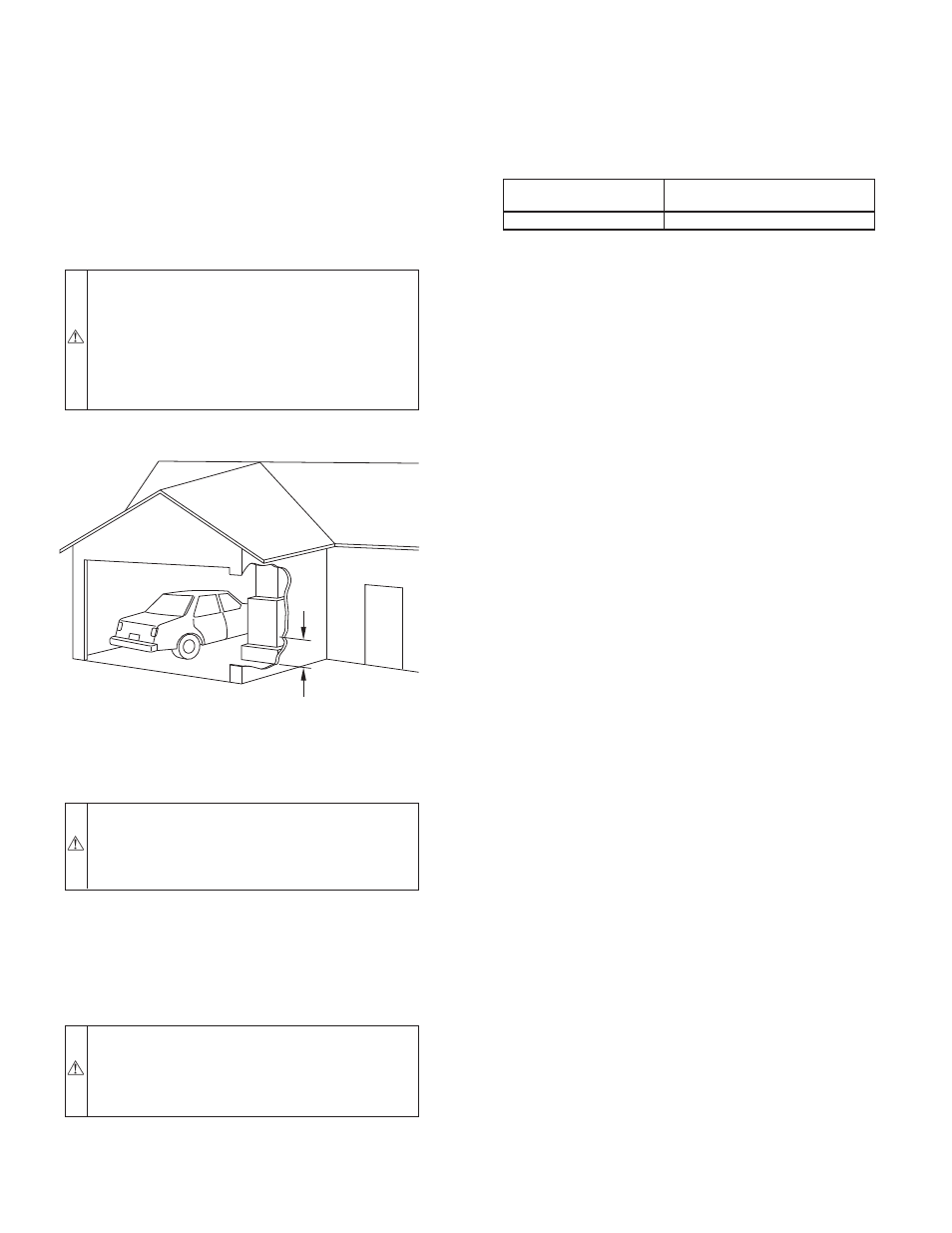

WARNING: When the furnace is installed in a residen-

tial garage, the burners and ignition sources must be

located at least 18 inches above the floor. The furnace

must be located or protected to avoid damage by vehicles.

When the furnace is installed in a public garage, airplane

hangar, or other building having a hazardous atmosphere,

the furnace must be installed in accordance with the

National Fire Protection Association, Inc. requirements.

CAUTION: Air for combustion must not be contami-

nated by halogen compounds, which include fluoride,

chloride, bromide, and iodide. These elements are found

in aerosol sprays, detergents, bleaches, cleaning solvents,

salts, air fresheners, and other household products.

All fuel-burning equipment must be supplied with air for fuel

combustion. Sufficient air must be provided to avoid negative

pressure in the equipment room or space. A positive seal must be

made between the furnace cabinet and the return-air duct to

prevent pulling air from the burner area and from blocked vent

safeguard opening.

CAUTION: The operation of exhaust fans, kitchen ven-

tilation fans, clothes dryers, or fireplaces could create a

NEGATIVE PRESSURE CONDITION at the furnace.

Make-up air MUST be provided for the ventilation

devices, in addition to that required by the furnace.

The requirements for combustion and ventilation air depend upon

whether the furnace is located in an unconfined or confined space.

I. UNCONFINED SPACE

An unconfined space has a volume of at least 50 cu ft for each

1000 Btuh total input for all appliances (furnaces, clothes dryers,

water heaters, etc.) in the space.

For example:

If the unconfined space is constructed unusually tight, air for

combustion and ventilation must come from either the outdoors or

spaces freely communicating with the outdoors. Combustion and

ventilation openings must be equivalent to those used for a

confined space (defined below). Return air must not be taken from

the room unless an equal or greater amount of air is supplied to the

room.

II. CONFINED SPACE

A confined space has a volume less than 50 cu ft per 1000 Btuh

of total input ratings of all appliances installed in that space. A

confined space must have provisions for supplying air for com-

bustion, ventilation, and dilution of flue gases using 1 of the

following methods in Table 2 and Fig. 7and 8.

NOTE: When determining the free area of an opening, the

blocking effect of louvers, grilles, and screens must be considered.

If the free area of the louver or grille design is unknown, assume

wood louvers have a 20 percent free area and metal louvers or

grilles have a 60 percent free area. Screens must not be smaller

than 1/4-in. mesh. Louvers and grilles must be constructed so they

cannot be closed.

The opening size depends upon whether air comes from outside of

the structure or an unconfined space inside the structure.

1. Air from inside the structure requires 2 openings (for

structures not of unusually tight construction):

a. Each opening must have a minimum free area of not less

than 1 sq in per 1000 Btuh of total input rating for all gas

utilization equipment in the confined space, but not less

than 100 sq in. The minimum dimension of air openings

should be no smaller than 3 in. (See Table 2 and Fig. 7

and 8).

b. If building construction is unusually tight, a permanent

opening directly communicating with the outdoors shall

be provided. (See next section).

c. If the furnace is installed on a raised platform to provide

a return-air plenum, and return air is taken directly from

the hallway or space adjacent to furnace, all air for

combustion must come from outdoors.

2. Air from outside the structure requires 1 of the following:

a. If combustion air is taken from outdoors through 2

vertical ducts, the openings and ducts must have at least

1 sq in. of free area per 4000 Btuh of total input for all

equipment within the confined space. (See Fig. 8 and

Table 2.)

b. If combustion air is taken from outdoors through 2

horizontal ducts, the openings and ducts must have at

least 1 sq in. of free area per 2000 Btuh of total input for

all equipment within the confined space. (See Fig. 8 and

Table 2.)

c. If combustion air is taken from the outdoors through a

single opening or duct (horizontal or vertical) commenc-

ing within 12 in. of the top of the confined space, the

opening and duct must have at least 1 sq in. of free area

Fig. 6–Location to Burners

A93044

18-IN. (457.2 mm)

MINIMUM TO BURNERS

TABLE 1–312AAV FLOOR AREA

312AAV FURNACE

INPUT (BTUH)

MINIMUM WITH

7–1/2 FT CEILING (SQ. FT.)

88,000

587

—6—