Bryant 312AAV User Manual

Page 14

Two male 1/4–in quick-connect terminals, marked EAC-1

and EAC-2 are provided for EAC connection. (See Fig. 22.)

These terminals are energized with 115-v, (1.0-amp maxi-

mum) during blower motor operation. To connect EAC

power leads to furnace control, install 1/4–in. female

quick-connect terminals on EAC power leads.

2. Humidifier (HUM)

Screw terminals HUM (1/4-in male quick-connect) and

C

OM

-24V are provided for 24-v humidifier connection. The

terminals are energized with 24-v 0.5-amp maximum when

gas valve is energized.

WARNING: DO NOT connect furnace control HUM

terminal to HUM (humidifier) terminal on Thermidistat,

Zone Controller or similiar device. See Thermidistat™,

Zone Controller, thermostat, or controller manufacturer’s

instructions for proper connection. A failure to follow this

warning could result in fire.

NOTE: A field-supplied, 115-v controlled relay connected to

EAC terminals may be added if humidifier operation is desired

during blower operation.

D. Venting

See Fig. 20, Venting Orientation for approved vent configurations.

Refer to the national or local installtion code such as NFGC in the

U.S. or the NSCNGPIC in Canada for proper vent sizing and

installation requirements. Use the enclosed Installation Instruc-

tions (Vent Tables for 1-and 2-stage Category I Fan-Assisted

Furnaces) for a quick, easy reference.

NOTE: Vent sizing length starts at furnace vent elbow.

Rotate furnace vent elbow to position desired. Remove U-shaped

cut-out (knockout) on door to clear the vent pipe. Support the vent

pipe at the furnace with metal pipe strap.

After fully assembling the vent connector to the furnace vent

elbow, securely fasten the vent connector to the vent elbow with

two field-supplied, corrosion-resistant, sheet metal screws located

180° apart.

The horizontal portion of the venting system shall maintain a

minimum of 1/4-in. upward slope per linear ft and it shall be

rigidly supported every 5 ft or less with hangers or straps to ensure

that there will be no movement after installation.

START-UP, ADJUSTMENT, AND SAFETY CHECK

I. GENERAL

NOTE: Proper polarity must be maintained for 115-v wiring. If

polarity is incorrect, control status indicator light will flash rapidly

and furnace will not operate.

The furnace must have a 115-v power supply properly connected

and grounded. Proper polarity must be maintained for correct

operation. Thermostat wire connections at R, W, C, and Y must be

made at the 24-v terminal block on the furnace control. The gas

service pressure must not exceed 0.5 psig (14-in. wc), but must be

no less than 0.16 psig (4.5-in. wc).

CAUTION: This furnace is equipped with manual reset

limit switches in the gas control area. The switches open

and shut off power to the gas valve, if a flame rollout or

overheating condition occurs in the gas control area. DO

NOT bypass the switches. Correct inadequate combustion

air supply problem and reset the switches.

Before operating furnace, check each manual-reset switch for

continuity.

The blower compartment door must be in place to complete the

115–v circuit to the furnace.

II. SEQUENCE OF OPERATION

CAUTION: Furnace control must be grounded for

proper operation or control will lockout. Control is

grounded through green wire rotated to gas valve and

burner bracket screw.

Using the schematic diagram in Fig. 23, follow the sequence of

operation through the different modes. Read and follow the wiring

diagram very carefully.

NOTE: If a power interruption occurs during a call for heat

(W/W1 or W/W1-and-W2), the control will start a 90-second

blower-only ON period two seconds after power is restored, if the

thermostat is still calling for gas heating. The green LED light will

flash code 12 during the 90-second period, after which the LED

will be ON continuous, as long as no faults are detected. After the

90-second period, the furnace will respond to the thermostat

normally.

The blower door must be installed for power to be conducted

through the blower door interlock switch ILK to the furnace

control CPU, transformer TRAN, inducer motor IDM, blower

motor BLWM, hot-surface igniter HSI, and gas valve GV.

1. Two-Stage Heating (Adaptive mode) with Single-Stage

Thermostat

(See Fig. 21 for thermostat connections)

This furnace can operate as a two-stage furnace with a

single-stage thermostat because the furnace control CPU

includes a programmed adaptive sequence of controlled

operation, which selects low-heat or high-heat operation.

This selection is based upon the stored history of the length

of previous gas-heating periods of the single-stage thermo-

stat.

The furnace will start up in either low- or high-heat. If the

furnace starts up in low-heat, the control CPU determines

the low-heat on-time (from 0 to 16 minutes) which is

permitted before switching to high-heat.

If the power is interrupted, the stored history is erased and

the control CPU will initially select low-heat for up to 16

minutes and then switch to high-heat, as long as the

thermostat continues to call for heat. Subsequent selection

is based on stored history of the thermostat cycle times.

The wall thermostat

″calls for heat″, closing the R to W

circuit. The furnace control performs a self-check, verifies

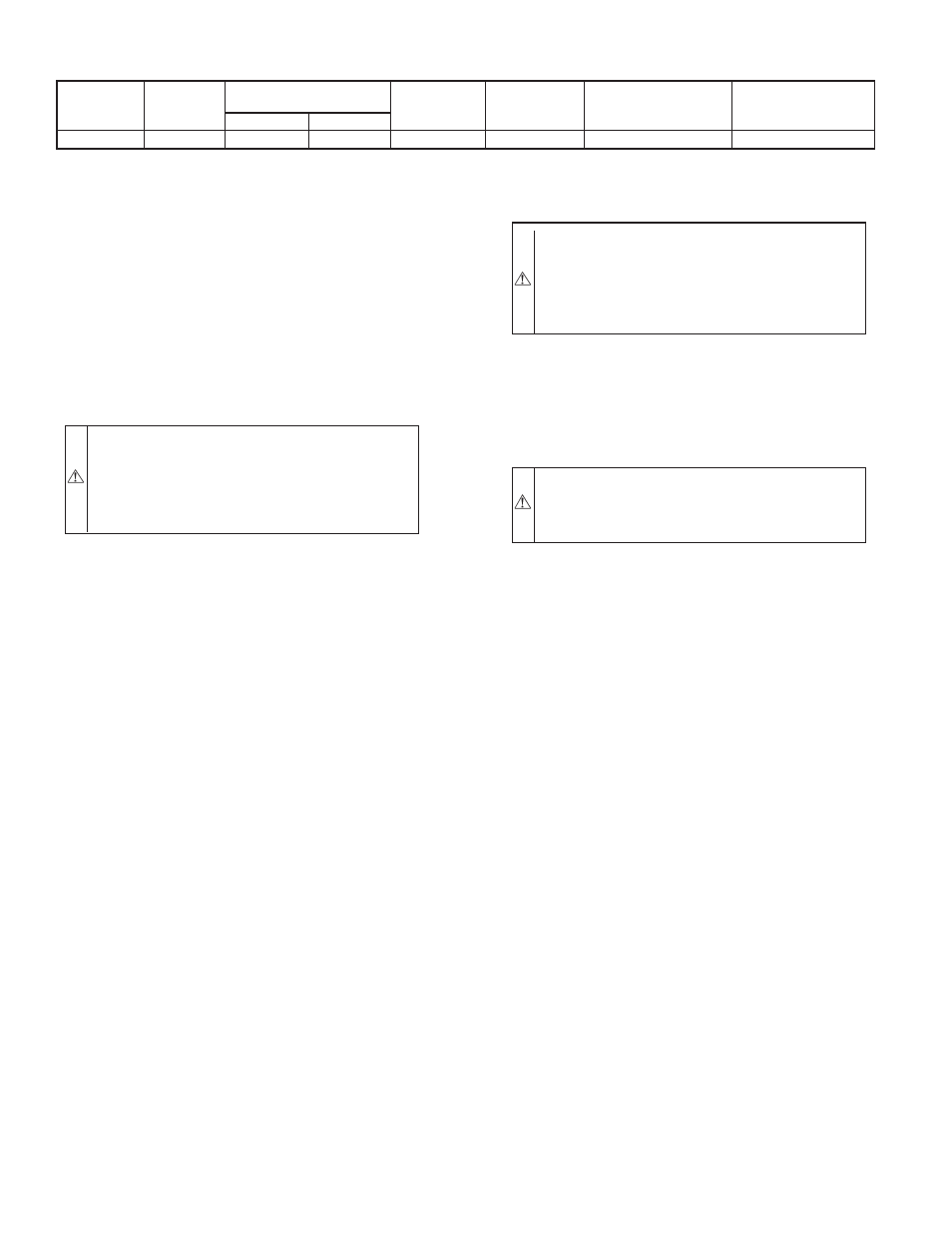

TABLE 6–ELECTRICAL DATA

UNIT SIZE

VOLTS-

HERTZ-

PHASE

OPERATING

VOLTAGE RANGE

MAXIMUM

UNIT AMPS

MINIMUM

WIRE GAGE

MAXIMUM

WIRE LENGTH (FT)‡

MAXIMUM

FUSE OR CKT BKR

AMPS†

Maximum*

Minimum*

042090

115–60–1

127

104

9.0

14

31

15

* Permissible limits of the voltage range at which the unit operates satisfactorily.

† Time-delay type is recommended.

‡ Length shown is as measured 1 way along wire path between unit and service panel for maximum 2 percent voltage drop.

—14—