Bryant 312AAV User Manual

Page 4

CAUTION: Application of this furnace should be in-

doors with special attention given to vent sizing and

material, gas input rate, air temperature rise, and unit

sizing. Improper installation or misapplication may re-

quire excessive servicing or cause premature component

failure.

WARNING: Improper installation, adjustment, alter-

ation, service, maintenance, or use can cause carbon

monoxide poisoning, explosion, fire, electrical shock, or

other conditions which may cause personal injury or

property damage. Consult a qualified installer, service

agency, local gas supplier, or your distributor or branch

for information and assistance. The qualified installer or

agency must use only factory-authorized and listed kits or

accessories when modifying this product.

Failure to follow this warning could result in electrical

shock, fire, personal injury or death.

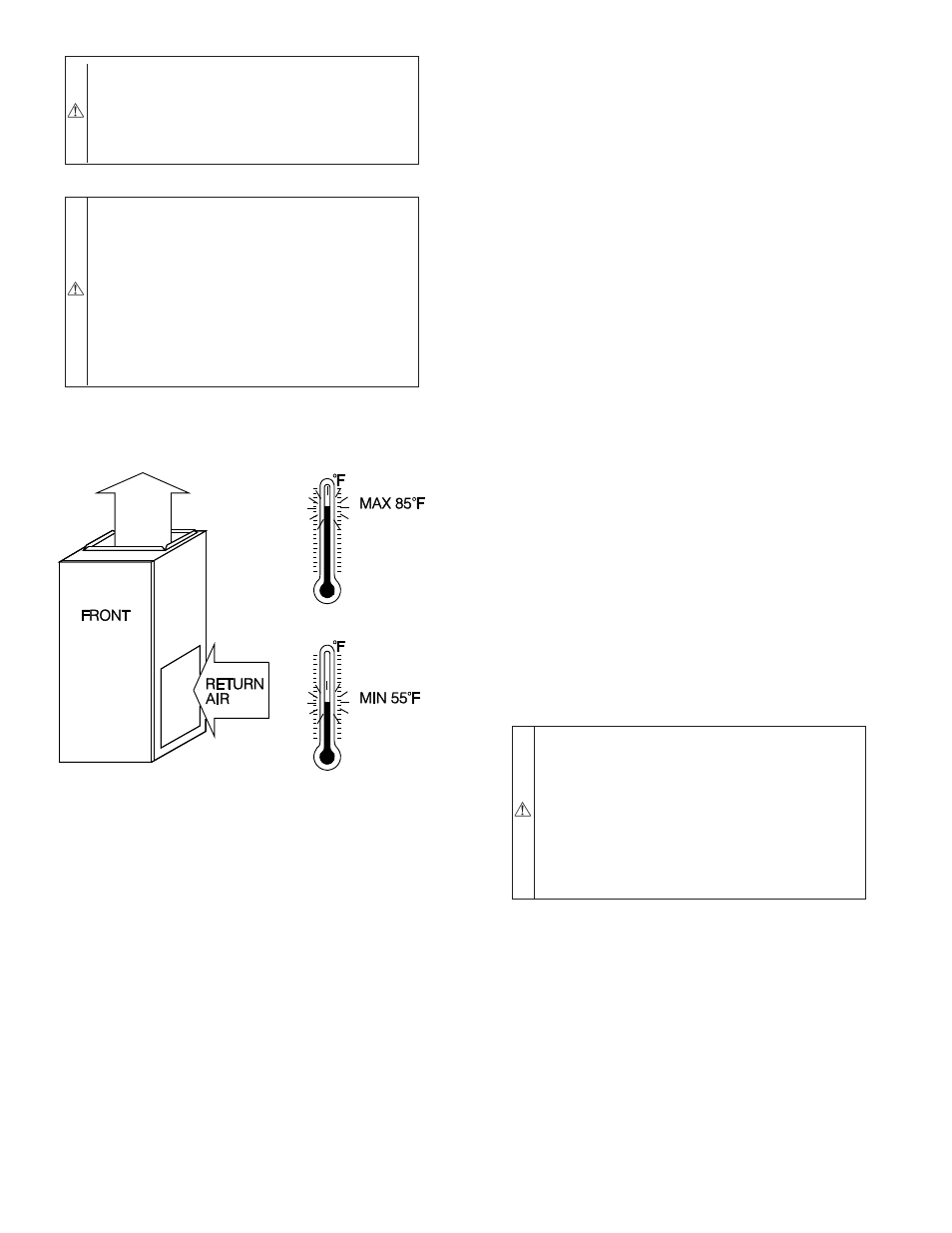

This furnace is designed for minimum continuous return-air

temperature of 60°F db or intermittent operation down to 55°F db.

Return-air temperature must not exceed 85°Fdb. (See Fig. 3.)

For accessory installation details, refer to the applicable instruction

literature.

NOTE: Remove all shipping brackets and materials before oper-

ating the furnace.

CODES AND STANDARDS

Follow all national and local codes and standards in addition to

these instructions. The installation must comply with regulations

of the serving gas supplier, local building, heating, plumbing, and

other codes. In absence of local codes, the installation must

comply with the national codes listed below and all authorities

having jurisdiction.

In the United States and Canada, follow all codes and standards for

the following:

I. SAFETY

• US: National Fuel Gas Code (NFGC) NFPA 54–1999/ANSI

Z223.1–1999 and the Installation Standards, Warm Air Heating

and Air Conditioning Systems ANSI/NFPA 90B

• CANADA: CAN/CGA-B149.1–and .2–M95 National Standard

of Canada. Natural Gas and Propane Installation Codes (NSC-

NGPIC)

II. GENERAL INSTALLATION

• US: Current edition of the NFGC and the NFPA 90B. For

copies, contact the National Fire Protection Association Inc.,

Batterymarch Park, Quincy, MA 02269; or for only the NFGC,

contact the American Gas Association, 400 N. Capitol, N.W.,

Washington DC 20001

• CANADA: NSCNGPIC. For a copy, contact Standard Sales,

CSA International, 178 Rexdale Boulevard, Etobicoke (Tor-

onto), Ontario, M9W 1R3 Canada

III. COMBUSTION AND VENTILATION AIR

• US: Section 5.3 of the NFGC, Air for Combustion and

Ventilation

• CANADA: Part 7 of NSCNGPIC, Venting Systems and Air

Supply for Appliances

IV. DUCT SYSTEMS

• US and CANADA: Air Conditioning Contractors Association

(ACCA) Manual D, Sheet Metal and Air Conditioning Con-

tractors National Association (SMACNA), or American Soci-

ety of Heating, Refrigeration, and Air Conditioning Engineers

(ASHRAE) 1997 Fundamentals Handbook Chapter 32.

V. ACOUSTICAL LINING AND FIBROUS GLASS DUCT

• US and CANADA: current edition of SMACNA and NFPA

90B as tested by UL Standard 181 for Class I Rigid Air Ducts

VI. GAS PIPING AND GAS PIPE PRESSURE TESTING

• US: NFGC; chapters 2,3,4, and 9 and National Plumbing Codes

• CANADA: NSCNGPIC Part 5

VII. ELECTRICAL CONNECTIONS

• US: National Electrical Code (NEC) ANSI/NFPA 70–1999

• CANADA: Canadian Electrical Code CSA C22.1

ELECTROSTATIC DISCHARGE (ESD) PRECAUTIONS

PROCEDURE

Use this procedure for all installed and uninstalled furnaces. An

ESD service kit (available from commercial sources) may be used

to prevent ESD damage.

CAUTION: Electrostatic discharge can affect electronic

components. Follow the Electrostatic Discharge Precau-

tions Procedure listed below during furnace installation

and servicing to protect the furnace electronic control.

Precautions will prevent electrostatic discharges from

personnel and hand tools which are held during the

procedure. These precautions will help to avoid exposing

the control to electrostatic discharge by putting the

furnace, the control, and the person at the same electro-

static potential.

1. Disconnect all power to the furnace. Multiple disconnects

may be required. DO NOT TOUCH THE CONTROL OR

ANY WIRE CONNECTED TO THE CONTROL PRIOR

TO DISCHARGING YOUR BODY’S CHARGE TO

GROUND.

2. Firmly touch a clean, unpainted metal surface on the

furnace chassis close to the control. Tools held in hand

during grounding will be discharged.

3. You may proceed to service the control or connecting wires

as long as you do nothing to recharge your body (moving or

shuffling feet, touching ungrounded objects, etc.)

4. If you touch ungrounded objects, firmly touch a clean,

unpainted metal surface again before touching control or

wires.

Fig. 3–Return Air Temperature

A93042

—4—