Bryant 312AAV User Manual

Page 8

DOWNFLOW FURNACES

Connect supply-air duct to supply-air opening on furnace. The

supply-air duct attachment must ONLY be connected to furnace

supply/outlet or air conditioning coil casing (when used). When

installed on combustible material, supply-air duct attachment must

ONLY be connected to an accessory subbase or factory approved

air conditioning coil casing. DO NOT cut main furnace casing to

attach supply side air duct, humidifier, or other accessories. All

accessories MUST be connected external to furnace casing. Supply

air opening duct flanges must be modified per Fig. 14.

HORIZONTAL FURNACES

Connect supply-air duct to supply air opening on furnace. The

supply-air duct attachment must ONLY be connected to furnace

supply/outlet or air conditioning coil casing (when used). DO NOT

cut main furnace casing to attach supply side air duct, humidifier,

or other accessories. All accessories MUST be connected external

to furnace casing. Supply air opening duct flanges must be

modified per Fig. 14.

D. Return Air Connections

DOWNFLOW AND HORIZONTAL FURNACES

WARNING: Never connect return-air ducts to the back

of the furnace. A failure to follow this warning can cause

a fire, personal injury, or death.

The return-air duct must be connected to return-air opening

(bottom inlet) as shown in Fig. 1. DO NOT cut into casing sides

(left or right). Side opening is permitted for only upflow furnaces.

Bypass humidifier connections should be made at ductwork or coil

casing sides exterior to furnace.

UPFLOW FURNACES

The return-air duct must be connected to bottom, sides (left or

right), or a combination of bottom and side(s) of main furnace

casing as shown in Fig. 1. Bypass humidifier may be attached into

unused side return air portion of the furnace casing.

INSTALLATION

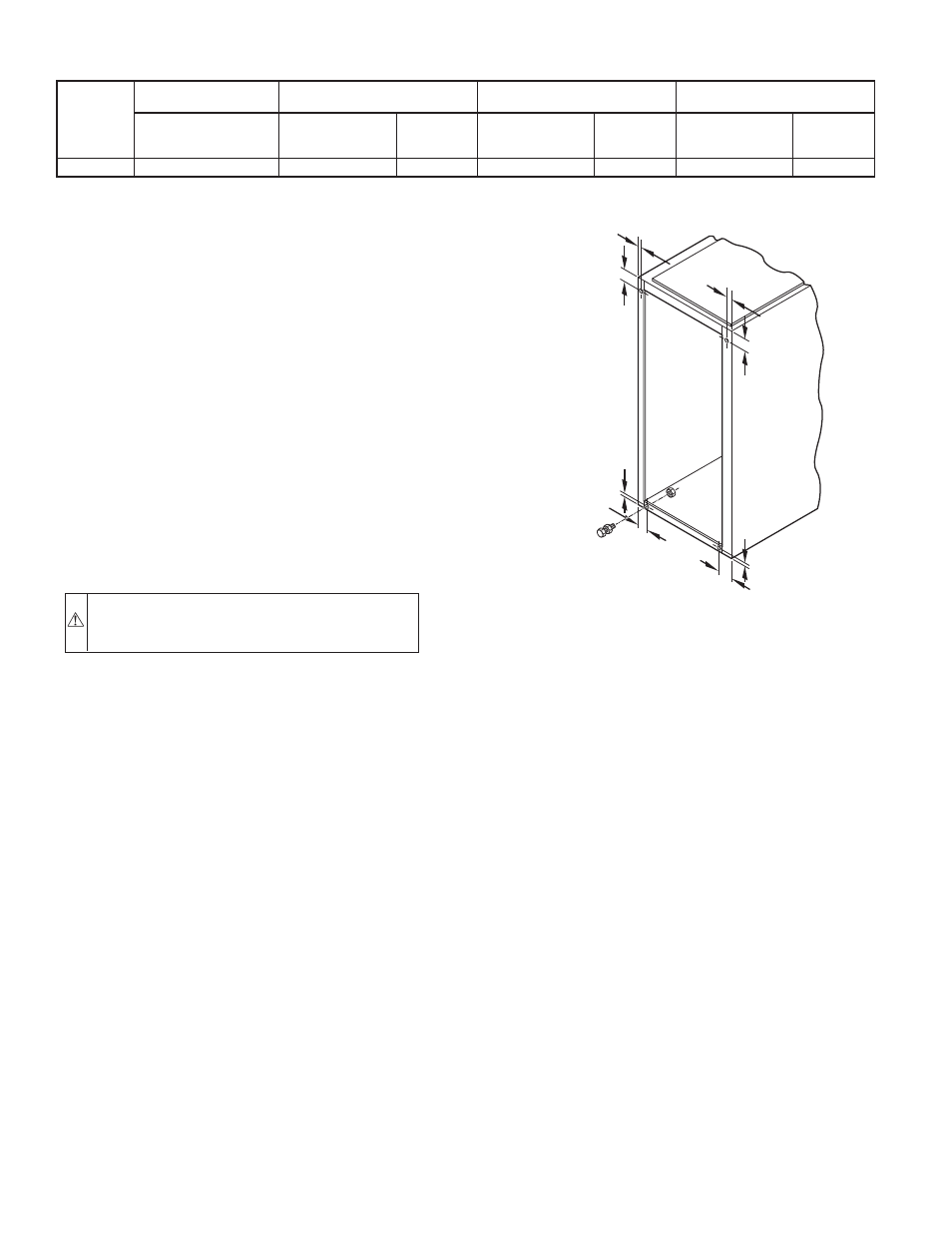

I. LEVELING LEGS (IF DESIRED)

When furnace is used in upflow position with side inlet(s), leveling

legs may be desired. (See Fig. 9.) Install field-supplied, corrosion-

resistant 5/16-in. machine bolts and nuts.

NOTE: The maximum length of bolt should not exceed 1-1/2 in.

1. Position furnace on its back. Locate and drill a 5/16-in.

diameter hole in each bottom corner of furnace. (See Fig.

9.) Holes in bottom closure panel may be used as guide

locations.

2. For each hole, install nut on bolt and then install bolt and

nut in hole. (Install flat washer if desired.)

3. Install another nut on other side of furnace base. (Install flat

washer if desired.)

4. Adjust outside nut to provide desired height, and tighten

inside nut to secure arrangement.

NOTE: Bottom closure must be used when leveling legs are used.

NOTE: Remove and discard bottom closure panel when bottom

inlet is used.

II. BOTTOM CLOSURE PANEL

These furnaces are shipped with bottom closure panel installed in

bottom return-air opening. This panel MUST be in place when side

return air is used.

To remove bottom closure panel, perform the following:

1. Tilt or raise furnace and remove 2 screws holding front

filler panel. See Fig. 10)

2. Rotate front filler panel downward to release holding tabs.

3. Remove bottom closure panel.

4. Reinstall front filler panel and screws.

NOTE: Side return-air openings can ONLY be used in UPFLOW

configurations.

III. DOWNFLOW INSTALLATION

NOTE: For downflow applications, this furnace is approved for

use on combustible flooring when special base (Part No.

KGASB0201ALL) is used. Special base is not required when this

furnace is installed on manufacturer’s Coil Assembly Part No.

CD5 or CK5, or Coil Box Part No. KCAKC is used.

1. Determine application being installed from Table 3.

2. Construct hole in floor per dimensions specified in Table 3

and Fig. 11.

3. Construct plenum to dimensions specified in Table 3 and

Fig. 11.

4. If downflow subbase (KGASB) is used, install as shown in

Fig. 12.

TABLE 2–MINIMUM FREE AREA OF COMBUSTION AIR OPENING*

312AAV

FURNACE

INPUT

(BTUH)

AIR FROM INDOOR

UNCONFINED SPACE

OUTDOOR AIR THROUGH

VERTICAL DUCTS

OUTDOOR AIR THROUGH

HORIZONTAL DUCTS

OUTDOOR AIR THROUGH

SINGLE DUCT

Free Area

of Opening

(Sq In.)

Free Area of

Opening and Duct

(Sq. In.)

Round Pipe

(in. Dia)

Free Area of

Opening and Duct

(sq In.)

Round Pipe

(in. Dia)

Free Area of

Opening and Duct

(Sq In.)

Round Pipe

(In. Dia)

88,000

100

22.0

6

44.0

8

29.33

7

* Free area shall be equal to or greater than the sum of the areas of all vent connectors in the confined space. Opening area must be increased if other gas appliances in

the space require combustion air.

Fig. 9–Leveling Legs

A89014

1

3

/

4

″

1

3

/

4

″

1

3/

4

″

1

3/

4

″

5/

16

″

5

/

16

″

5/

16

″

5/

16

″

(44mm)

(8mm)

(44mm)

(8mm)

(8mm)

(8mm)

(44mm)

(44mm)

—8—