Step 9) boost inductor specifications, An368 – Cirrus Logic AN368 User Manual

Page 38

AN368

38

AN368REV2

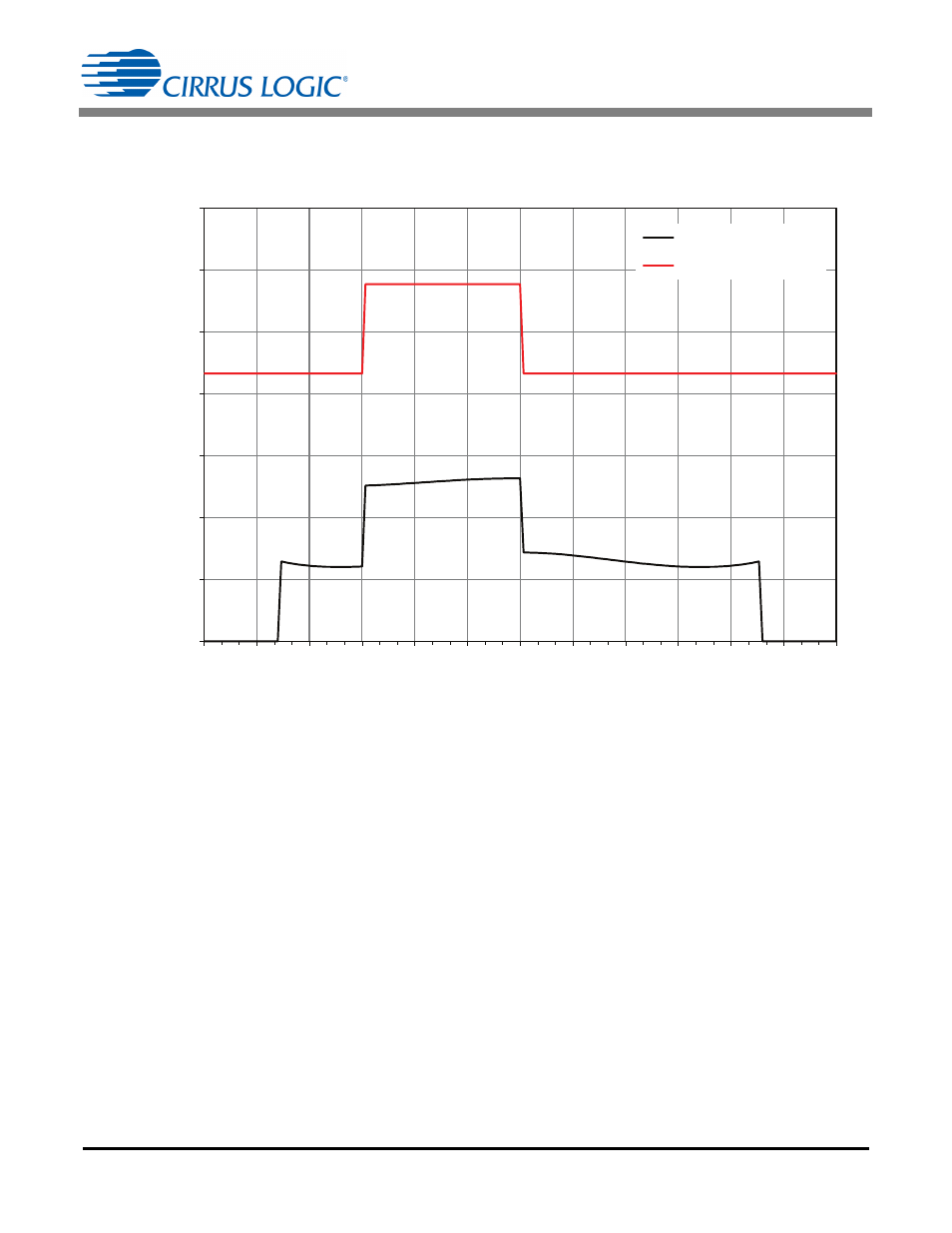

The AC line current does not follow the inductor peak current envelope because the circuit operates in CRM

and DCM. The switching frequency and duty cycle changes across the AC line phase, resulting in a changing

average value after the EMI filter smoothing.

During circuit adjustment, connect an electronic load in CV mode for testing and clamp protection. Set the

electronic load so that the boost output voltage is 425V for a 230V system (CS1631) or 215V for a 120V

system (CS1630). Measure the switching frequency at the nominal line voltage. Adjust I

PK(BST)

to obtain the

desired waveform at the peak of the line voltage, as shown in Figure 18.

Step 9) Boost Inductor Specifications

The CS1630 controls I

PK(BST)

and keeps the boost stage operating in CRM. Boost inductance L

BST

only

controls the average switching frequency. The instantaneous frequency changes to meet the I

PK(BST)

imposed

by the controller, and the duty cycle imposed by the CRM/DCM algorithm.

The boost inductor should be designed for 600mA at 3000Gauss and the maximum ambient temperature. For

a given input voltage design, the product of (L

BST

·

P

IN

) is constant. Choose the frequency range on Figure 19

to find the corresponding (L

BST

·

P

IN

) product, and divide the product by P

IN

to obtain L

BST

.

0.00

0.02

0.04

0.06

0.08

0.10

0.12

0.14

0

15

30

45

60

75

90

105

120

135

150

165

180

Cur

rent (A

)

Phase Angle (°)

AC Line Current

Inductor Peak Current

Figure 18. Current vs Phase Angle