Pulsatrol removal, Back pressure valve, Pressure relief valve – Pulsafeeder Pulsar Shadow User Manual

Page 52

46

PULSAtrol Removal

When removing or disassembling a PULSAtrol, drain all piping and remove all air and process pressure.

Assume that the diaphragm is broken and the chamber is flooded under pressure since the pressure

gauge could be damaged. Separate chambers with caution in a direction away from the body.

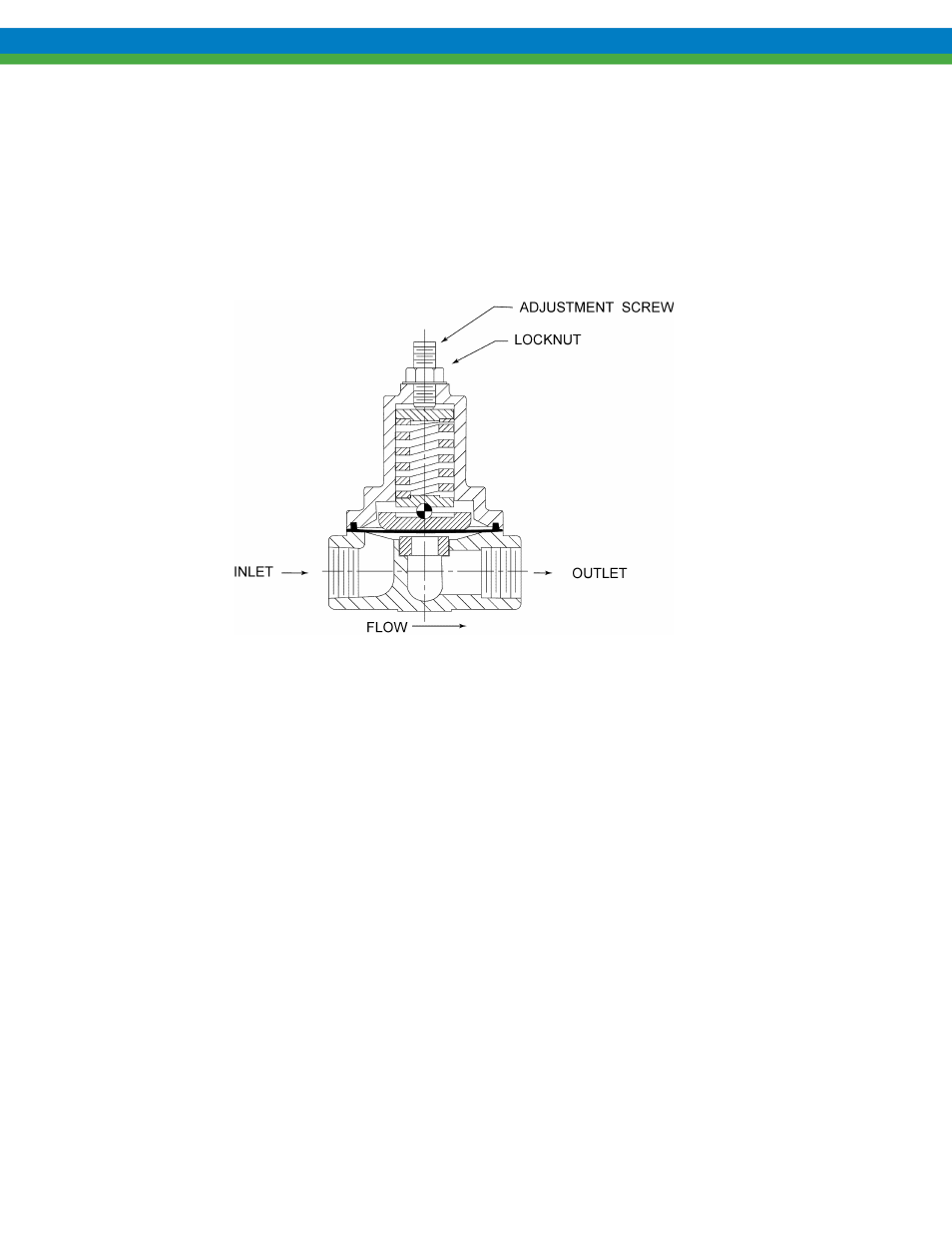

Back Pressure Valve

Figure 29

The Pulsafeeder diaphragm backpressure valve creates constant backpressure. A TFE diaphragm,

offering maximum chemical protection and service life, seals spring and bonnet from product. This

diaphragm seals directly on a replaceable seat.

Be sure to install with fluid flow in direction of arrow on valve body. If arrow is missing from plastic

valve body, install with flow exiting out center hole of valve body.

Pressure Relief Valve

Pressure relief valves should be utilized in any system to protect the pump and other process equipment

and piping from potentially damaging or unsafe pressures. It is critical that the pressure relief valve be

mounted in the discharge piping system before any other devices that can potentially block or impede

flow, or it cannot perform its intended function (refer to Figure 8).

The pressure relief valve must be set to a pressure high enough to prevent unwanted fluid relief during

normal process conditions. A setting that is approximately 10-20% above normal operating pressures is

generally sufficient. The valve must also be set below the maximum pressure capability of the lowest

rated device in the system. For example, if a PULSAR pump is rated with a maximum pressure

capability of 150 psi (approx. 10 bar) but the piping within the system is rated only to a maximum of

100 psi (approx. 7 bar) then the pressure relief valve must be set to a value lower than 100 psi.