Calibration, 5 calibration – Pulsafeeder Pulsar Shadow User Manual

Page 20

15

6.5

Calibration

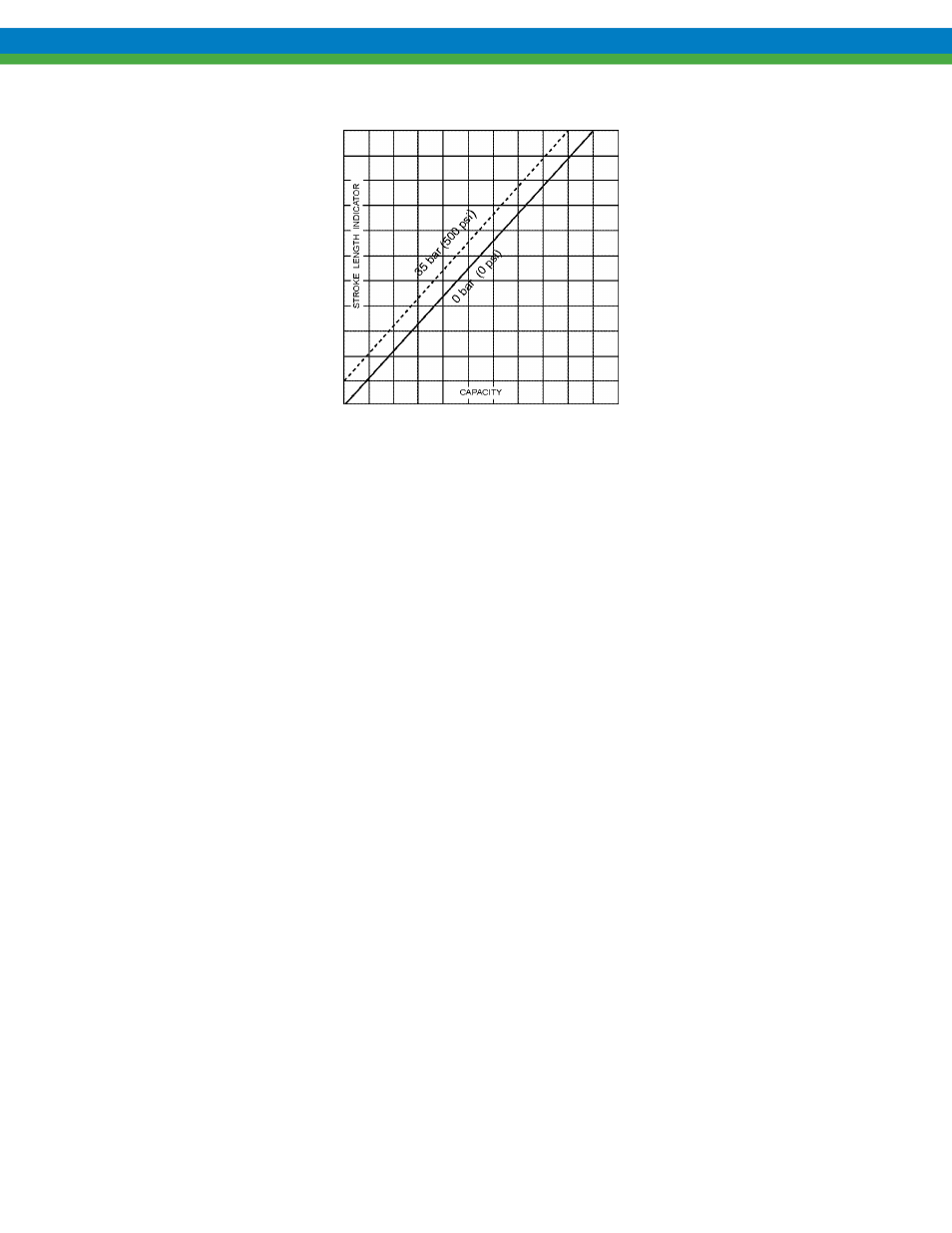

Figure 13

All metering pumps must be calibrated in order to accurately specify stroke length settings for required

flow rates. For pumps provided with DLC or DLCM electronic stoke length control, refer to separate

instructions as noted on page 8.

A typical calibration chart is shown in Figure 13. Although output is linear with respect to stroke

length setting, an increase in discharge pressure decreases output uniformly, describing a series of

parallel lines, one for each pressure (only two are shown).

The theoretical output flow rate at atmospheric output pressure is based on the displacement of the

hydraulic piston (the product of piston cross-sectional area and stroke length) and the stroking rate of

the pump. With increasing discharge pressure there is a corresponding decrease in output flow of

approximately 1% per 7 bar (100 psig) increase in output pressure. Whenever possible, calibration

should be performed under actual process conditions (i.e., the same or a similar process liquid at system

operating pressure).

To assure a sound hydraulic system, run the pump for 10-15 minutes prior to calibration. This will

allow the PTP (automatic bleed) valve to purge any air from the system.

To construct a calibration chart, measure the flow rate several times at three or more stroke settings (i.e.,

25, 50, 75, and 100), plot these values on linear graph paper, and draw a best-fit line through the points.

For stable conditions, this line should predict settings to attain required outputs.

Checking the actual flow rates is especially important in pumps producing low flow rates and operating

against high discharge pressures. In this type of system, normal losses of efficiency can result in lack of

measurable flow at shorter piston stroke lengths. This is a function of the system conditions and does

not indicate a problem with the pump. Careful measurement of actual pump flow at several test points

will allow for proper calibration over the complete flow range.