Startup procedure, Output adjustment, 1 output adjustment – Pulsafeeder Pulsar Shadow User Manual

Page 18

13

6. Startup Procedure

6.1

Output Adjustment

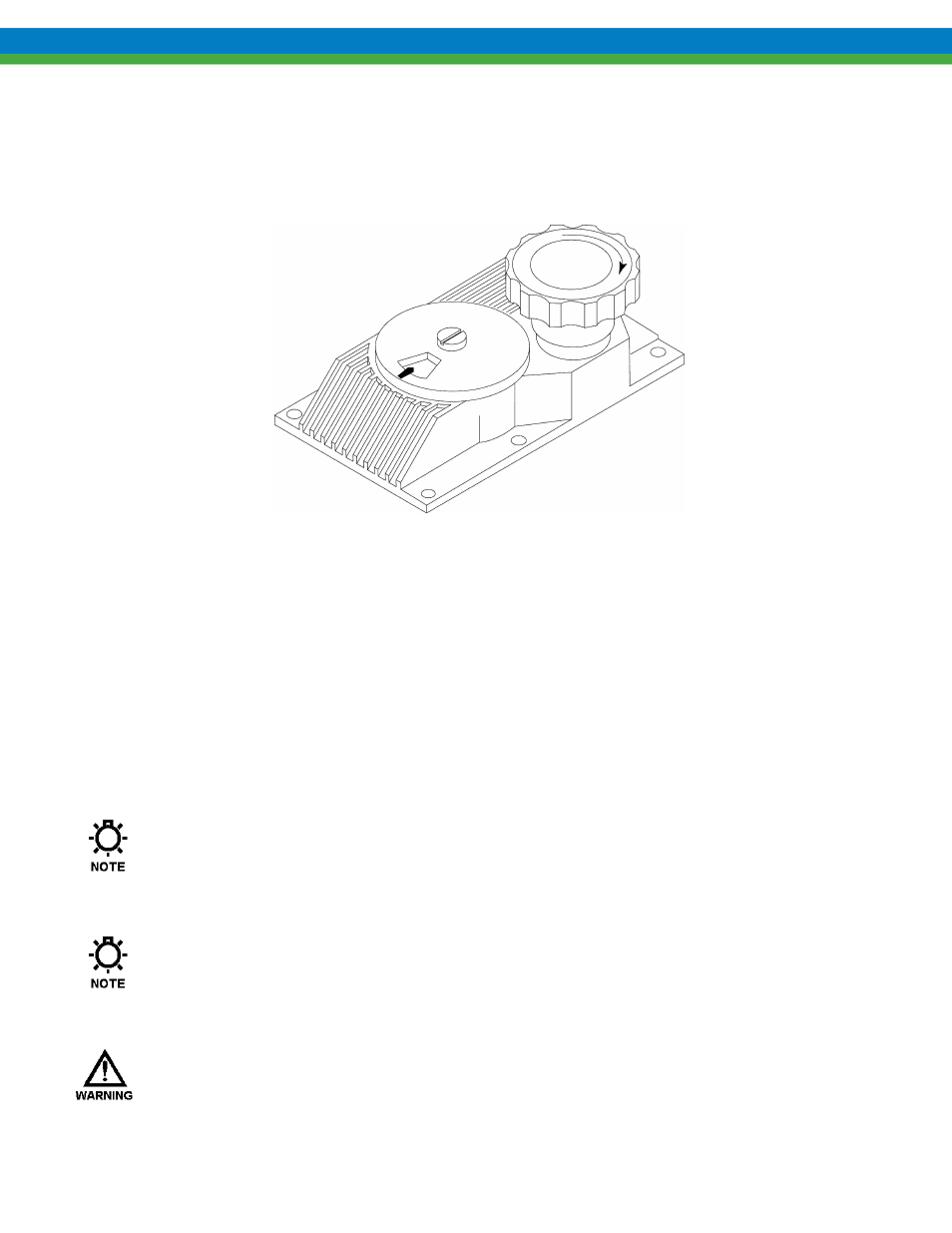

Figure 12

All PULSAR pumps have a hand-wheel for manual stroke length adjustment. Mounted atop the

eccentric box, the hand-wheel can be adjusted at any point (from 0 to 100% stroke setting) by pressing

down and then rotating the hand wheel as required. Stroke length is locked during operation to prevent

drift: pressing the hand-wheel down temporarily disengages the lock for adjustment; release after

adjustment automatically resets the lock at the new setting. An indicator adjacent to the hand-wheel

displays the output setting. Adjustments can be made while the pump is at rest or operating, although

operating adjustments are easier to make. Manual adjustment serves as a backup for pumps provided

with an optional DLC stroke length controller. If the control cover is removed and replaced, the bolts

should be tightened to 20-24 In-lb (225 – 270 N-cm).

If the pump is equipped with a vacuum leak detection system, vacuum must be maintained at

all times during pump operation, whether or not leak detection is required. If the proper level

of vacuum (between 10 in and 26 in. (250mm to 650mm) Hg) is not present, decreased flow

and/or diaphragm damage will occur. See Appendix I on page 33 for further information.

If the pump is equipped with a pressure leak detection system, the system must remain sealed at

all times during pump operation, whether or not leak detection is required. If the seal is broken,

decreased flow and/or diaphragm damage will occur. See Appendix I on page 33 for further

information.

Leak Detection Diaphragm systems require special hydraulic priming considerations to protect

the diaphragm from damage during initial pump startup. See Appendix I on page 33 for further

information.