Re-priming the pumphead, 2 re-priming the pumphead – Pulsafeeder Pulsar Shadow User Manual

Page 25

20

7.2.2

Re-Priming the Pumphead

Leak Detection diaphragm systems

require special hydraulic priming

considerations to protect the

diaphragm from damage during

initial pump startup. Refer to

Appendix I, page 33 and review these

procedures carefully before re-

starting a PULSAR pump equipped

with a leak detection system.

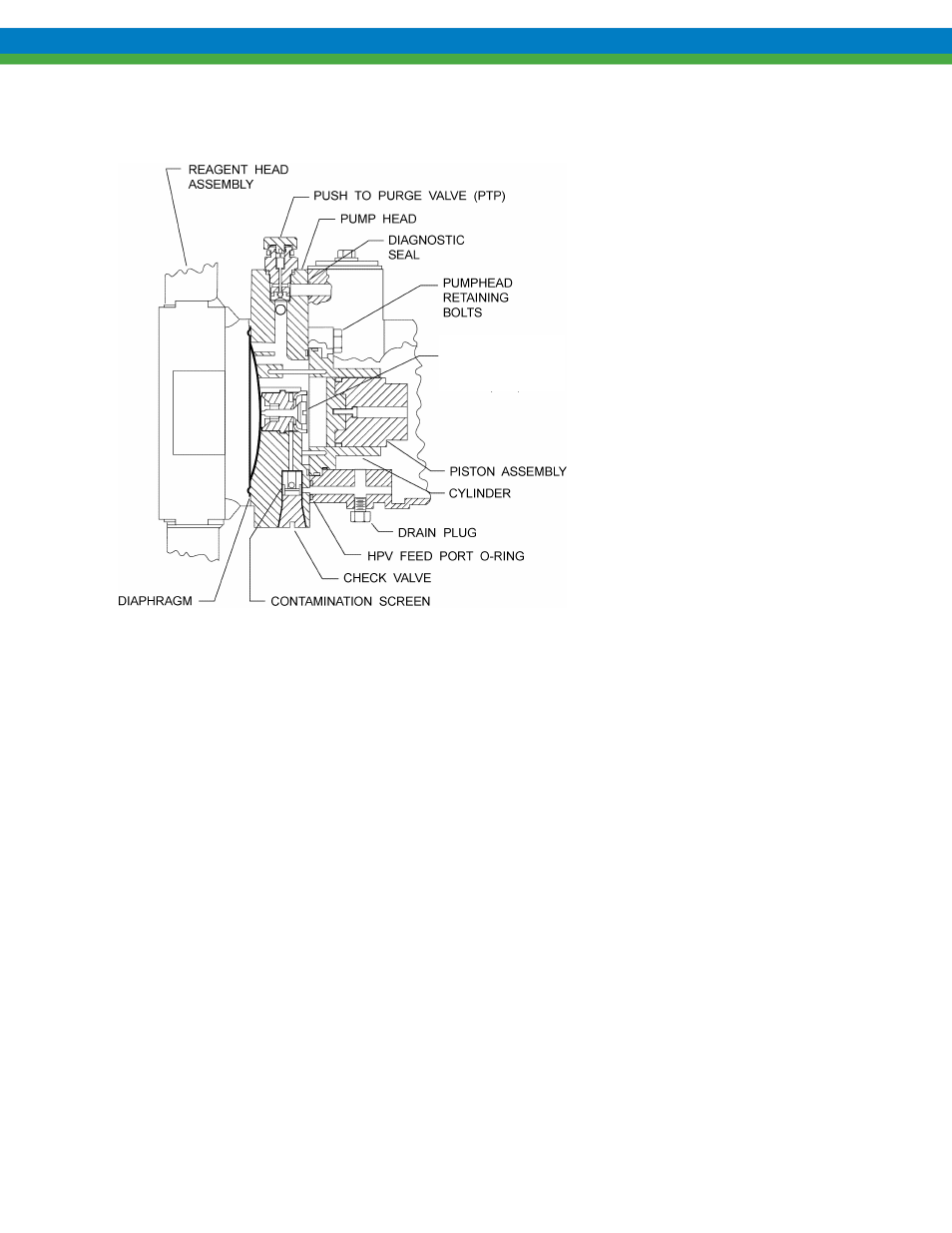

Figure 15

Hydraulic Priming Procedure, for standard Composite (THY) and Solid (PTFE) diaphragms:

1. Disconnect the power source to the drive motor.

2. Relieve all pressure from the piping system and where possible allow liquid to enter the reagent

head assembly.

3. Remove the diagnostic window and fill the eccentric box with PULSAlube 7H hydraulic oil to the

proper level. Replace the diagnostic window.

4. Turn on the pump and adjust the stroke length to the maximum setting of 100%.

5. Fully depress and hold the PTP valve. After several minutes oil should begin to flow out of the

center diagnostic port. Continue to hold the valve down until the oil is clear of bubbles. The

pump is now primed. If oil fails to flow out of the diagnostic port, proceed to step 6.

6. Reset to the zero stroke length setting, and turn off the pump. Setting the pump to zero stroke

moves the piston forward to prevent diaphragm damage at startup.

7. Remove the PTP valve from the pumphead. Using a small plastic funnel, slowly pour oil into the

pumphead through the PTP valve port until full.

8. Replace the PTP valve, ensuring that the flat copper gasket and o-ring are properly in place.

9. Turn on the pump. Gradually raise the stroke to the full 100% setting. Fully depress and hold the

PTP valve. Oil should begin to flow out of the center diagnostic port. Continue to hold the valve

down until the oil is clear of bubbles. If oil fails to flow out of the diagnostics port, then

additional oil is required in the pumphead: repeat steps (6) and (7) above.

HYDRAULIC

PERFORMANCE

VALVE (HPV)