Drive motor installation, Motor rotation, Motor installation – Pulsafeeder Pulsar Shadow User Manual

Page 17: Electrical

12

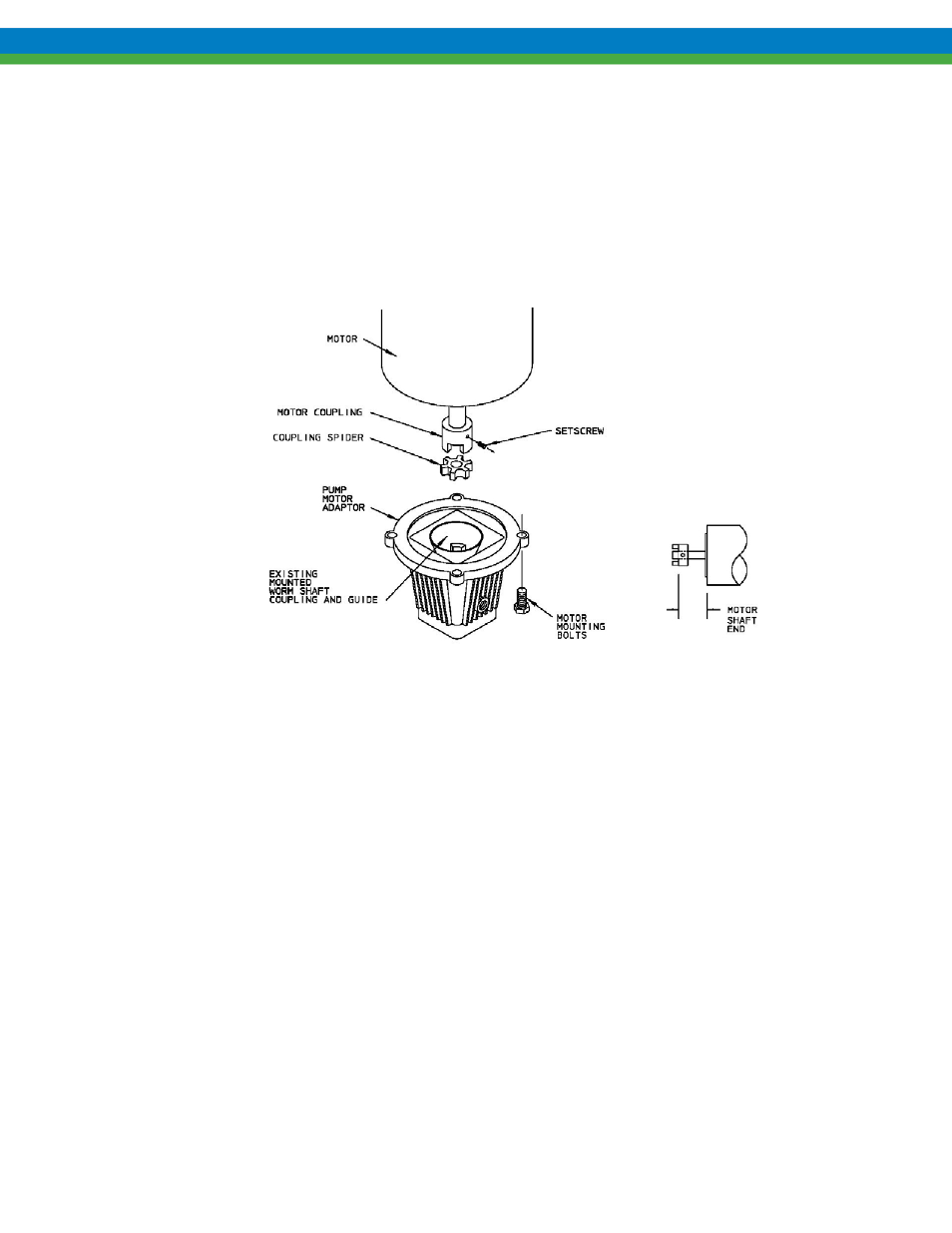

Drive Motor Installation

5.2.1

Motor Rotation

Motor can be operated in either direction, clockwise or counterclockwise. Verification of motor

direction is not necessary at startup.

5.2.2

Motor Installation

PULSAR pumps may be shipped with the drive motor packed separately. This is done to avoid damage

during transport.

Figure 11

1. Remove the unattached coupling half from the motor adaptor. Ensure that the elastomer

coupling spider remains in place, on the coupling half that remains attached to the worm shaft.

2. If applicable, remove any tape or retainer rings that hold the motor shaft key in place.

3. Place the loose coupling half on the motor shaft. Align the keyway with the key and align shaft

end to inner coupling surface as shown in figure above.

4. Tighten the setscrew onto the shaft key.

5. Place the motor in a vertical position and align the coupling teeth.

6. Install the motor downwards onto the adaptor. The plastic guide will assist in aligning the

coupling halves. Final position can be achieved by slightly rotating the motor until the coupling

jaws align.

7. Rotate the motor until the clearance holes in the adaptor and the tapped holes in the motor align.

Fasten the motor to the adaptor using the supplied bolts (4). Tighten bolts evenly to secure

motor.

5.2.3

Electrical

Wire the PULSAR drive motor according to the motor vendor’s nameplates and instructions, and

according to any appropriate national and local electrical codes and regulations.

If the motor is to be utilized with a Pulsafeeder controller, such as the DLC, DLCM, or MPC,

consult the appropriate Pulsafeeder IOM for further motor wiring instructions.