Leak detection option – setup for vacuum, Leak detection option – setup for pressure, 3 leak detection option – setup for vacuum – Pulsafeeder Pulsar Shadow User Manual

Page 40: 4 leak detection option – setup for pressure

34

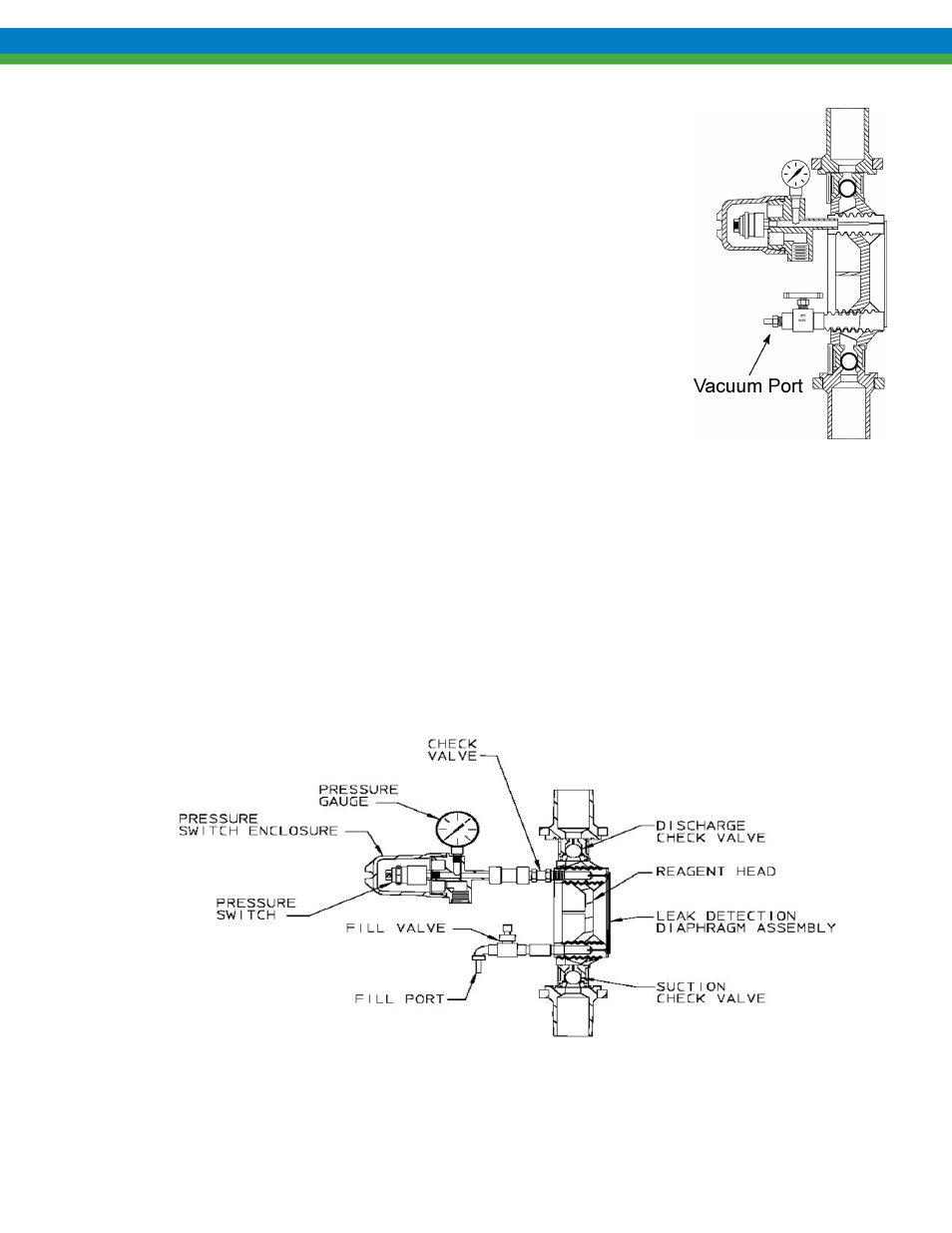

11.3 Leak Detection Option – Setup for Vacuum

A vacuum must be maintained at all times during pump operation,

otherwise, the diaphragm halves may separate during the suction stroke of

the pump, reducing flow capacity and potentially damaging the diaphragm.

Pumps incorporating the leak detection option are shipped from the factory

with the system evacuated to the operating vacuum of 650 mm Hg (26 in.

Hg). Due to flexure of the TFE diaphragms during transit and storage, the

initial vacuum may not be present at startup. When this occurs, re-evacuate

the system to the operating vacuum of 650 mm Hg (26 in. Hg).

1. Apply power to the alarm circuit.

2. Connect a vacuum pump capable of generating 26 inches of vacuum to

the Vacuum port, open the needle valve, and evacuate the system. A

hand-operated vacuum pump is generally appropriate for this procedure.

3. If required, verify system operation.

Figure 25

11.4 Leak Detection Option – Setup for Pressure

Pumps incorporating pressure leak detection are shipped from the factory with the system fully set up to

work at full pump pressure. No further setup is required. The standard factory barrier fluid is silicone

oil, if any other customer-specified media is used it must be compatible with construction materials.

The system will require proper setup after maintenance or repairs, see section 11.5 on the following

page for the proper procedure.

Figure 26