Diagnosis of diaphragm failure, 1 diagnosis of diaphragm failure – Pulsafeeder Pulsar Shadow User Manual

Page 38

32

10.1 Diagnosis of Diaphragm Failure

The following guide provides some potential causes of diaphragm failure; it is based upon visual

observation of the diaphragm. Careful observation of both the pump and the surrounding system is

necessary for proper diagnosis. This is only a guide, and may not include all potential causal factors.

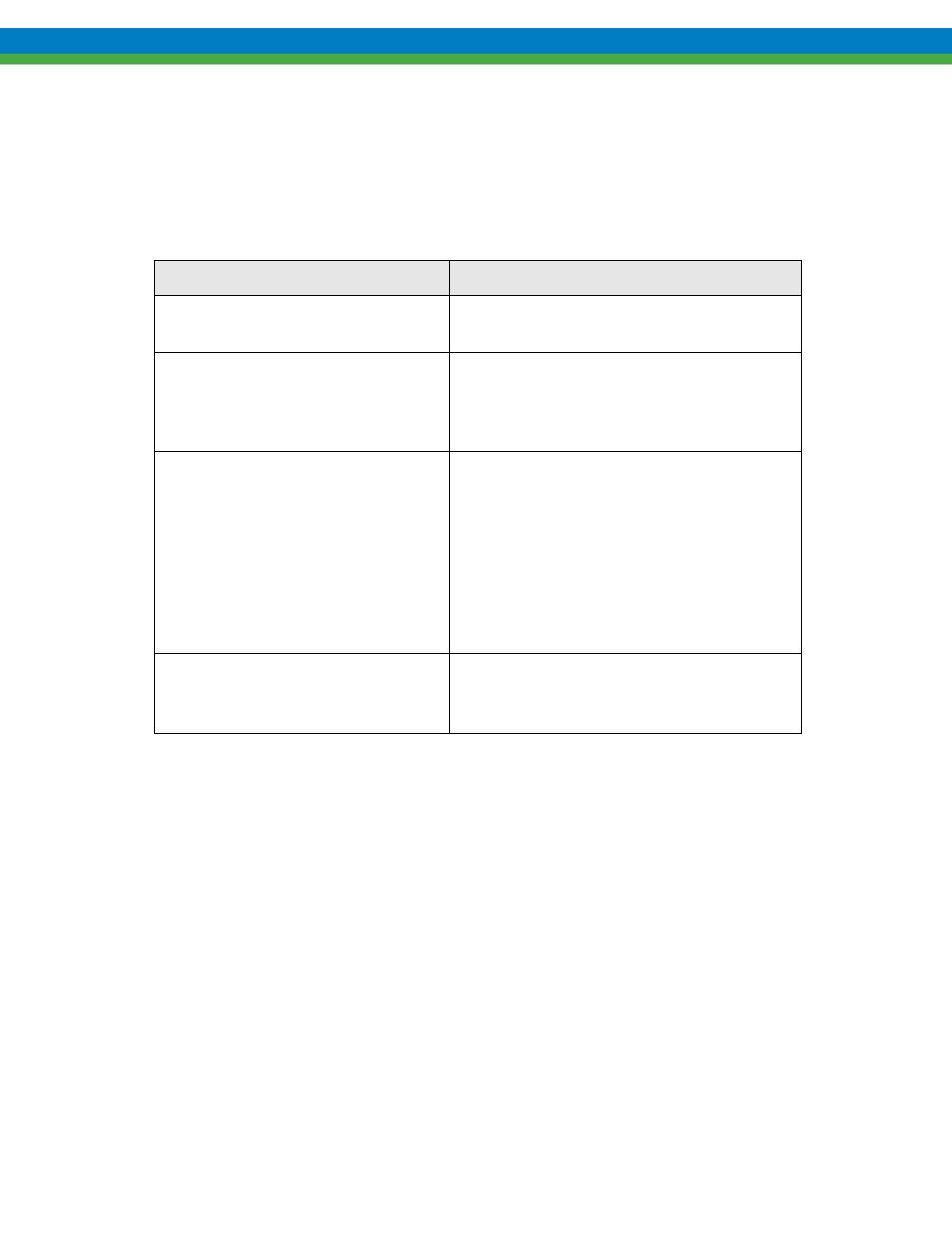

Failure Observed

Potential Causes

Puncture, surface wear, or physical

damage

Abrasives or solids in the process stream

Foreign object in process or hydraulic system

Extrusion and/or failure to the front

(towards the process end)

Extended time under poor suction conditions,

can include inadequate NPSH, closed valves,

clogged strainers or filters, obstructed piping

Malfunctioning HPV

Extrusion and/or failure to the rear

(towards the hydraulic end)

HPV filter screen clogged

High (excessive) suction pressure

Discharge pressure above maximum limit

Leaking (damaged) discharge check valve

Change in surface characteristics, color,

smoothness

Chemical incompatibility with the product