Duro-t – ROHM SUPER-LOCK User Manual

Page 12

1

3. Assembly, initialisation and dismantling

3.1 Assembly

3.1.1. Order of assembly

3.1.1.1 Draw bolt

In order to install the “SuperLock” locking unit, the first

step is to “pull out” the draw bolt from the complete mo-

dule which has been supplied fully mounted. The draw

bolt must then be installed in the spindle (receiver). It is

preferable to screw the draw bolt outside of the spindle

with the draw bolt extension (with an Allen wrench on

the head of the draw bolt - refer to table below for key

width). The mounting of the draw bolt can also be carried

out from the front with a standard sleeve socket wrench

and extension. The respective torque for the draw bolt is

also contained in table .

The draw bolt extension is inserted into the spindle from

the back and secured to the spindle depending upon the

individual construction of the spindle.

3.1.1.2 Clamping/release units and draw bolt

The next step is to mount the clamping and release unit.

In the release position, the position of the head end of

the draw bolt is measured in the spindle (illustration 5,

table , dimensions l1). Corrections to the position of the

draw bolt can only be undertaken on the clamping and

release unit or the draw bolt extension.

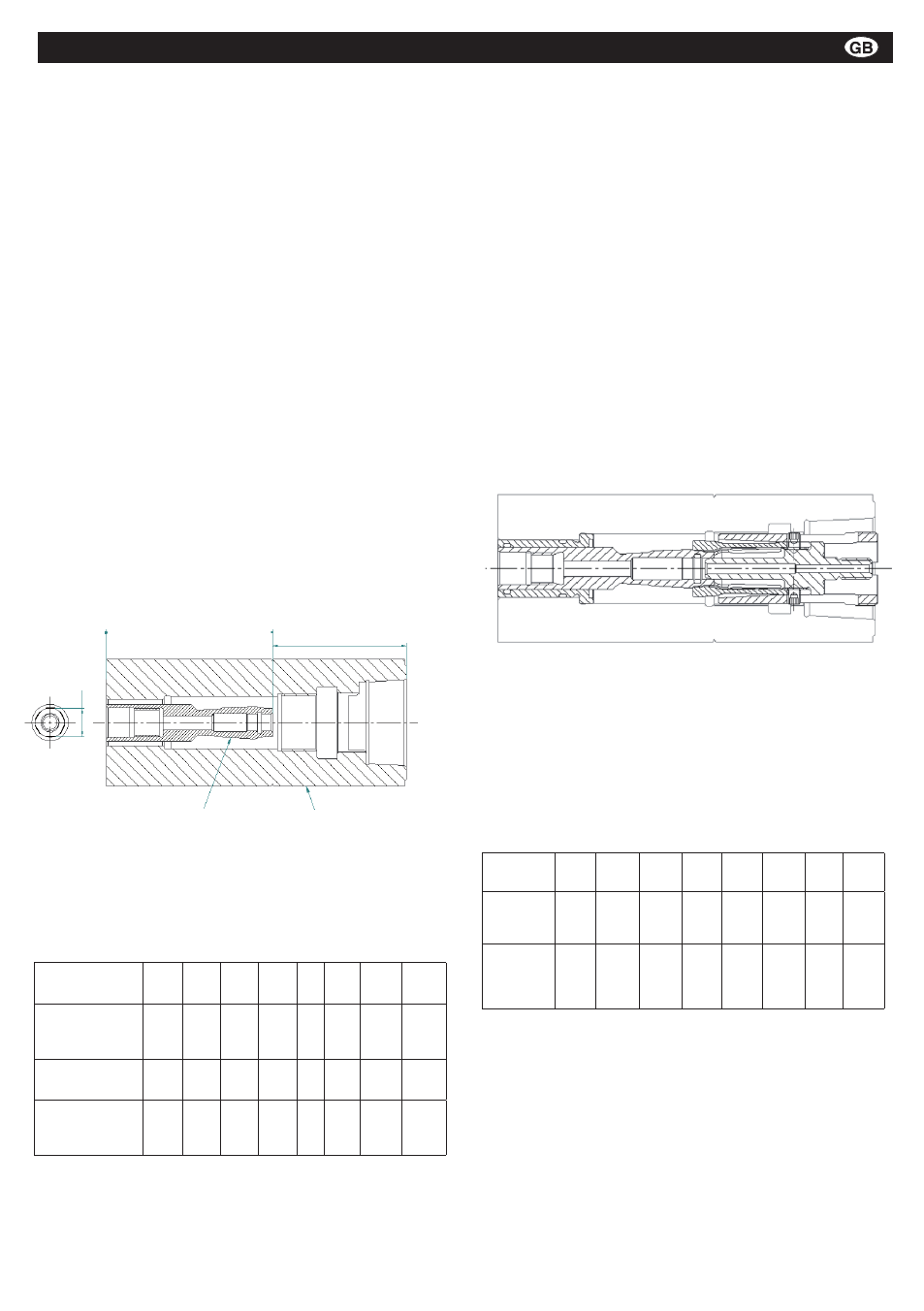

Illustration 5: control dimensions for the installation of the draw bolt

(l1), key width on the draw bolt (SW)

HSK nominal

size:

5

3

40

50

63 80

100

15

Key width on

the draw bolt

(SW):

6,35

8

10

1

15 19

8

Draw bolt tor-

que Mz (Nm):

5

10

0

40

80 150 50

400

Draw bolt-HSK

contact face l1

(mm):

30,4 36,5 47,5 56, 7 93,1 117,8 145,1

Key width (SW), torque (Mz) and control dimensions

for the draw bolt (l1)

3.1.1.3 Locking unit

First of all, the guide sleeve of the locking unit is inserted

in the spindle. Attention should be paid to the careful in-

sertion of the O-ring on the guide sleeve into the spindle

drill hole in order to avoid the shearing of the O-ring.

The module with clamping sleeve, collet and draw bar

is screwed into the spindle from the front. The movable,

protuding collet in the clamping sleeve is initially positi-

oned over the pull bolt without any screwing movement.

The collet is then manually placed on the head of the

draw bolt, the clamping sleeve is repositioned on the

collet as far as it will go on the rotation prevention screw

and is then pushed axial onto the draw bolt (compare

illustration 6) with some pressure. Depending upon

the HSK nominal size, this process is undertaken with

some application of force due to the spread of the collet.

Standard tools can be used as aids.

Assembly position

HSK nominal

size:

5

3

40

50

63

80

100 15

Röhm ID no

for mounting

wrench

117346 1143355 117611 1176114 117348 1176116 1176118 117610

Clamping

sleeve

torque Mh

(Nm)

15

5

35

50

70

95

15 160

Mounting wrench and torque for mounting the

clamping sleeve

Illustration 6: position of the collet in the clamping sleeve during

assembly of the draw bolt.

Once the collet has taken position on the draw bolt and

can be freely turned, the clamping sleeve can be scre-

wed in with a mounting wrench. The mounting wrench

required and the torque for the clamping sleeve are

included in table 3.

Table 2

Table 3

Montage- und Betriebsanleitung für

Fremdsprachentexte ...

Handspannfutter (Keilstangenprinzip)

Fremdsprachentexte ...

Fremdsprachentexte ...

mit Backensicherung

DURO-T

E

F

RUSS

Draw bolt

Spindle

l1

SW

0

0