Rogramming, Idden, Front display – Red Lion P16 User Manual

Page 9: 240 °f spsl, Sp-1

6.0 p

rogrAmming

: h

idden

l

oop

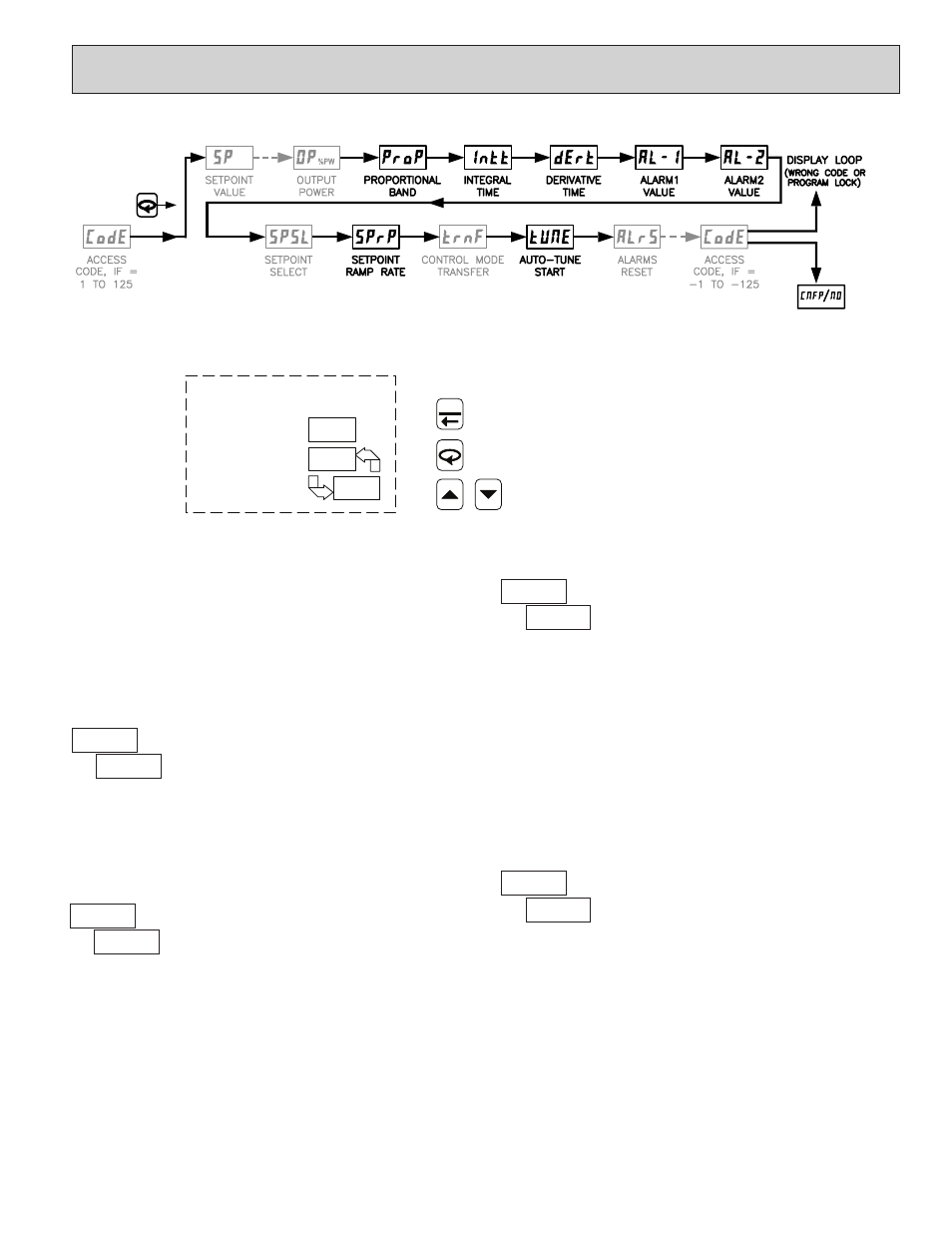

HIDDEN LOOP

Note: Parameters shown bold are the only parameters visible in the Hidden Loop with Factory Settings. Setpoint and Output Power are

factory set for the Display Loop. The remaining parameters can be selected for the Hidden Loop within Module 3.

Parameter availability is model and programming dependent.

FRONT DISPLAY

ENDS AND RETURNS TO START OF DISPLAY LOOP.

ADVANCES TO NEXT PARAMETER.

CHANGES SELECTION/VALUE.

240

°F

SPSL

TOP DISPLAY

TEMP/PROCESS

BOTTOM DISPLAY

PARAMETER

SELECTION/VALUE

SP-1

F1

To enter Hidden Loop, press A for 3 seconds.

HIDDEN LOOP

When A is pressed and held for three seconds, the controller advances to the

Hidden Loop. The Temperature/Process Value is shown in the top display. The

bottom display alternates between the parameter and its selection/value. B or

J

is pressed to change the selection/value for the shown parameter. The new

selection/value is activated after A is pressed. When L is pressed, the

controller returns to the Display Loop and stores changed selection/values to

permanent memory. Hidden Loop parameters may be locked out in Lockout

Module . Some parameters are model and programming dependent.

1

ACCESS CODE

1

to

12

If the Access Code is set from 1 to 125, in Lockout Module , Access

Code will appear here. By entering the proper Code, access to the Hidden Loop

is permitted. With the factory setting of 0, Access Code will not appear in the

Hidden Loop. A universal code of 111 can be entered to gain access,

independent of the programmed code number.

SETPOINT RAMP RATE

to

nF

CONTROL MODE TRANSFER

SETPOINT SELECT

1

or

2

The SPSL function allows the operator to switch from or to, setpoint 1 and

setpoint 2. In the Display Loop, there is no annunciator indicating the selected

Setpoint, however, the selected Setpoint value is displayed and activated.

In Automatic Mode, the percentage of Output Power is automatically

determined by the controller. In Manual/User Mode, the percentage of

Output Power is adjusted manually while in the Display Loop. The Control

Mode can also be transferred through the F1 Key or User Input. For more

information, see Control Mode Explanations.

The setpoint ramp rate can reduce sudden shock to the process and reduce

overshoot on startup or after setpoint changes, by ramping the setpoint at a

controlled rate. R annunciator flashes while ramping. With the T16, the ramp rate

is always in tenths of degrees per minute, regardless of the resolution chosen for

the process display. With the P16, the ramp rate is in least-significant (display

units) digits per minute. A value of 0.0 or 0 disables setpoint ramping. Once the

ramping setpoint reaches the target setpoint, the setpoint ramp rate disengages

until the setpoint is changed again. If the ramp value is changed during ramping,

the new ramp rate takes effect. If the setpoint is ramping prior to starting Auto-

Tune, the ramping is suspended during Auto-Tune and then resumed afterward.

Deviation and band alarms are relative to the target setpoint, not the ramping

setpoint. A slow process may not track the programmed setpoint rate. At power

up, the ramping setpoint is initialized at the ambient temperature/process value.

9