1 i, 2 module 2 - o, Utput – Red Lion P16 User Manual

Page 14: Arameters, Parameter menu

14

2

CYCLE TIME

to

2

seconds

OUTPUT POWER DAMPENING

to

2

seconds

The Cycle Time is entered in seconds with one tenth of a second resolution.

It is the total time for one on and one off period of the time proportioning

control output O1. With time proportional control, the percentage of power is

converted into an output on-time relative to the cycle time value set. (If the

controller calculates that 65% power is required and a cycle time of 10.0

seconds is set, the output will be on for 6.5 seconds and off for 3.5 seconds.)

For best control, a cycle time equal to one-tenth or less, of the natural period of

oscillation of the process is recommended. When using the Analog Output

signal for control, the Cycle Time setting has no effect. If the O1 output is not

being used, a cycle time of 0 can be entered to prevent the output and indicator

from cycling.

CONTROL ACTION

Direct (cooling)

Reverse (heating)

This determines the control action for the PID loop. Programmed for direct

action (cooling), the output power will increase if the Process value is above the

Setpoint value. Programmed for reverse action (heating), the output power

decreases when the Process Value is above the Setpoint Value. For heat and cool

applications, this is typically set to reverse. This allows O1 or A1 (models with

Analog Output) to be used for heating, and A2/O2 to be used for cooling.

OUTPUT POWER LOWER LIMIT

to

1

percent O1

1

to

1

percent O1/O2

This parameter may be used to limit controller power at the lower end due to

process disturbances or setpoint changes. Enter the safe output power limits for

the process. If Alarm 2 is selected for cooling, the range is from -100 to +100%.

At 0%, both O1 and O2 are off; at 100%, O1 is on; and at -100%, O2 is on.

When the controller is in Manual Control Mode, this limit does not apply.

1

I

OUTPUT POWER UPPER LIMIT

to

1

percent O1

1

to

1

percent O1/O2

This parameter may be used to limit controller power at the upper end due to

process disturbances or setpoint changes. Enter the safe output power limits for

the process. If Alarm 2 is selected for cooling, the range is from -100 to +100%.

At 0%, both O1 and O2 are off; at 100%, O1 is on; and at -100%, O2 is on.

When the controller is in Manual Control Mode, this limit does not apply.

AUTO-TUNE CODE

fastest to

2

slowest

Prior to starting Auto-Tune, this code should be set to achieve the necessary

dampening level under PID Control. This value allows customization of the PID

values that Auto-Tune will calculate. For the process to be controlled aggressively

(fastest process response with possible overshoot), set the Auto-Tune Code to 0.

For the process to be controlled conservatively (slowest response with the least

amount of overshoot), set this value to 2. If the Auto-Tune Code is changed,

Auto-Tune needs to be reinitiated for the changes to affect the PID settings. For

more information, see PID Tuning Explanations Section.

F

SENSOR FAIL POWER LEVEL

This parameter sets the power level for the control outputs in the event of a

sensor failure. If Alarm 2 is not selected for cooling, the range is from 0% (O1

output full off) to 100% (O1 output full on). If A2 is selected for cooling, the

range is from -100 to +100%. At 0%, both O1 and O2 are off; at 100%, O1 is

on; and at -100%, O2 is on. The alarm outputs are upscale drive with an open

sensor, and downscale drive with a shorted sensor (RTD only), independent of

this setting. Manual Control overrides the sensor fail preset.

The Dampening Time, entered as a time constant in seconds, dampens

(filters) the calculated output power. Increasing the value increases the

dampening effect. Generally, dampening times in the range of one-twentieth to

one-fiftieth of the controller’s integral time (or process time constant) are

effective. Dampening times longer than these may cause controller instability

due to the added lag effect.

ON/OFF CONTROL HYSTERESIS

1

to

2

The controller can be placed in the On/Off Control Mode by setting the

Proportional Band to 0.0%. The On/Off Control Hysteresis (balanced around

the setpoint) eliminates output chatter. In heat/cool applications, the control

hysteresis value affects both Output O1 and Output O2 control. It is suggested

to set the hysteresis band to Factory Setting prior to starting Auto-Tune. After

Auto-Tune, the hysteresis band has no effect on PID Control. On/Off Control

Hysteresis is illustrated in the On/Off Control Mode section.

1

T16

P16

2

2

T16

P16

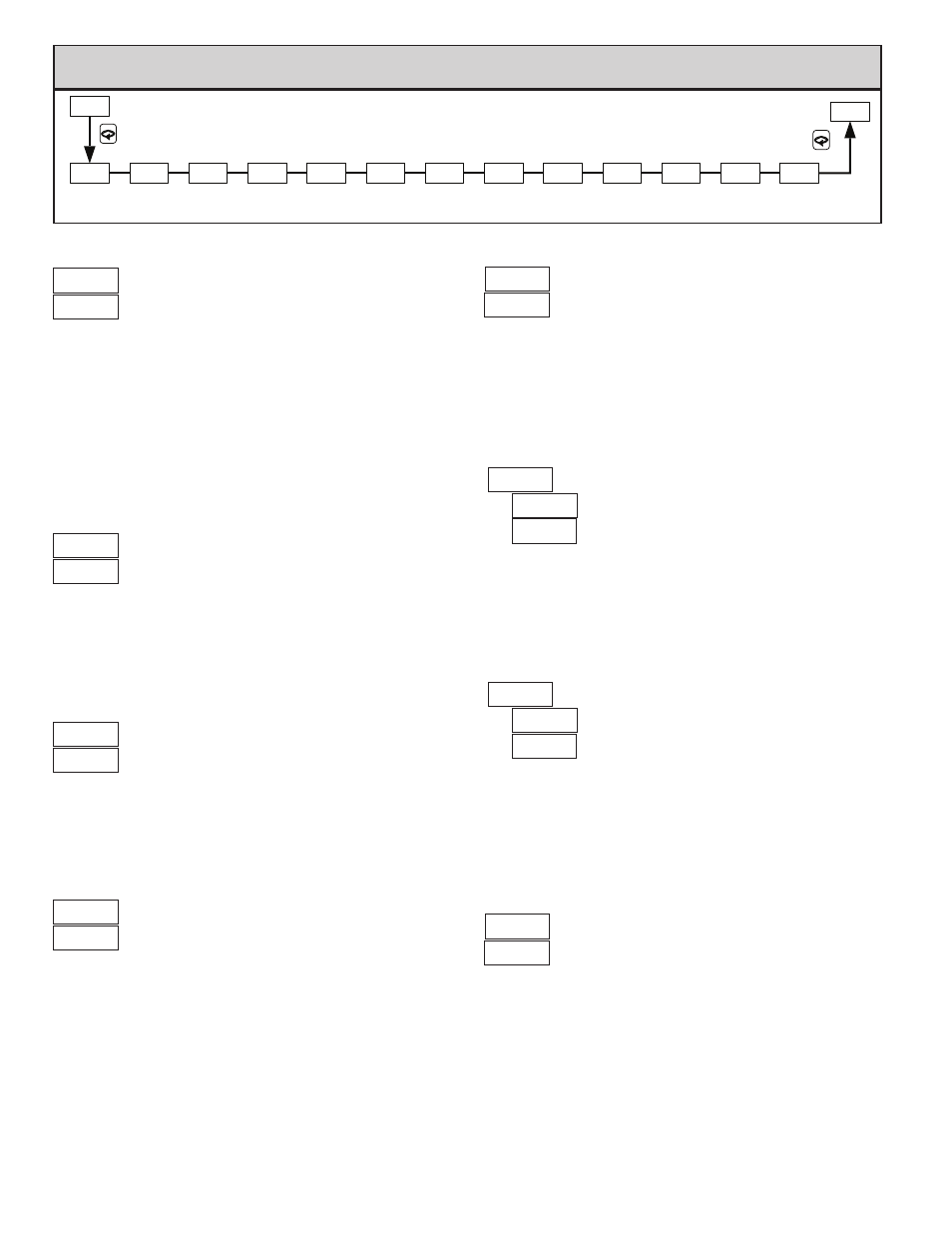

7.2 module 2 - o

utput

p

ArAmeterS

(

2-OP

)

CYCt

OPLO

OPAC

OPHI

OPFL

OPdP

CHYS

CYCLE

TIME

CONTROL

ACTION

OUTPUT

POWER

CONTROL

ON/OFF

OUTPUT

POWER

2-OP

CNFP

UPDATE

ANAS

OUTPUT

ANALOG

ANUt

ANALOG

ANALOG

ANHI

HIGH

ANLO

LOW

ANALOG

SENSOR FAIL

POWER

CODE

AUTO-TUNE

OUTPUT

ANALOG

tcod

ANtP

LOW LIMIT

HIGH LIMIT

POWER

OUTPUT

LEVEL

DAMPENING HYSTERESIS

RANGE

ASSIGNMENT

TIME

SCALING

SCALING

PARAMETER MENU

to

1

percent O1

1

to

1

percent O1/O2