Uning, Xplanations, 1i f – Red Lion P16 User Manual

Page 22: 11i, 2 n

22

TIME PROPORTIONAL PID CONTROL

In Time Proportional applications, the output power is converted into output

On time using the Cycle Time. For example, with a four second cycle time and

75% power, the output will be on for three seconds (4 × 0.75) and off for

one second.

The cycle time should be no greater than 1/10 of the natural period of

oscillation for the process. The natural period is the time it takes for one

complete oscillation when the process is in a continuously oscillating state.

LINEAR PID CONTROL

In Linear PID Control applications, the Analog Output Assignment is set

to % Output Power, . The Analog Low Scaling, , is set to 0.0 and the

Analog High Scaling, I , is set to 100.0. The Analog Output will then be

proportional to the PID calculated % output power for Heat or Cooling per the

Control Action . For example, with 0 VDC to 10 VDC (scaled 0 to 100%)

and 75% power, the analog output will be 7.5 VDC.

MANUAL CONTROL MODE

In Manual Control Mode, the controller operates as an open loop system

(does not use the setpoint and process feedback). The user adjusts the percentage

of power through the % Power display to control the power for Output O1.

When Alarm 2 is configured for Cooling (O2), Manual operation provides 0 to

100% power to O1 (heating) and -100 to 0% power to O2 (Cooling). The Low

and High Output Power limits are ignored when the controller is in Manual.

MODE TRANSFER

When transferring the controller mode between Automatic and Manual, the

controlling outputs remain constant, exercising true “bumpless” transfer. When

transferring from Manual to Automatic, the power initially remains steady, but

Integral Action corrects (if necessary) the closed loop power demand at a rate

proportional to the Integral Time.

AUTOMATIC CONTROL MODE

In Automatic Control Mode, the percentage of output power is automatically

determined by PID or On/Off calculations based on the setpoint and process

feedback. For this reason, PID Control and On/Off Control always imply

Automatic Control Mode.

p

id

t

uning

e

xplAnAtionS

AUTO-TUNE

Auto-Tune is a user-initiated function that allows the controller to

automatically determine the Proportional Band, Integral Time, Derivative Time,

Digital Filter, Control Output Dampening Time, and Relative Gain (Heat/Cool)

values based upon the process characteristics. The Auto-Tune operation cycles

the controlling output(s) at a control point three-quarters of the distance

between the present process value and the setpoint. The nature of these

oscillations determines the settings for the controller’s parameters.

Prior to initiating Auto-Tune, it is important that the controller and system be

first tested. (This can be accomplished in On/Off Control or Manual Control

Mode.) If there is a wiring, system or controller problem, Auto-Tune may give

incorrect tuning or may never finish. Auto-Tune may be initiated at start-up,

from setpoint or at any other process point. However, ensure normal process

conditions (example: minimize unusual external load disturbances) as they will

have an effect on the PID calculations.

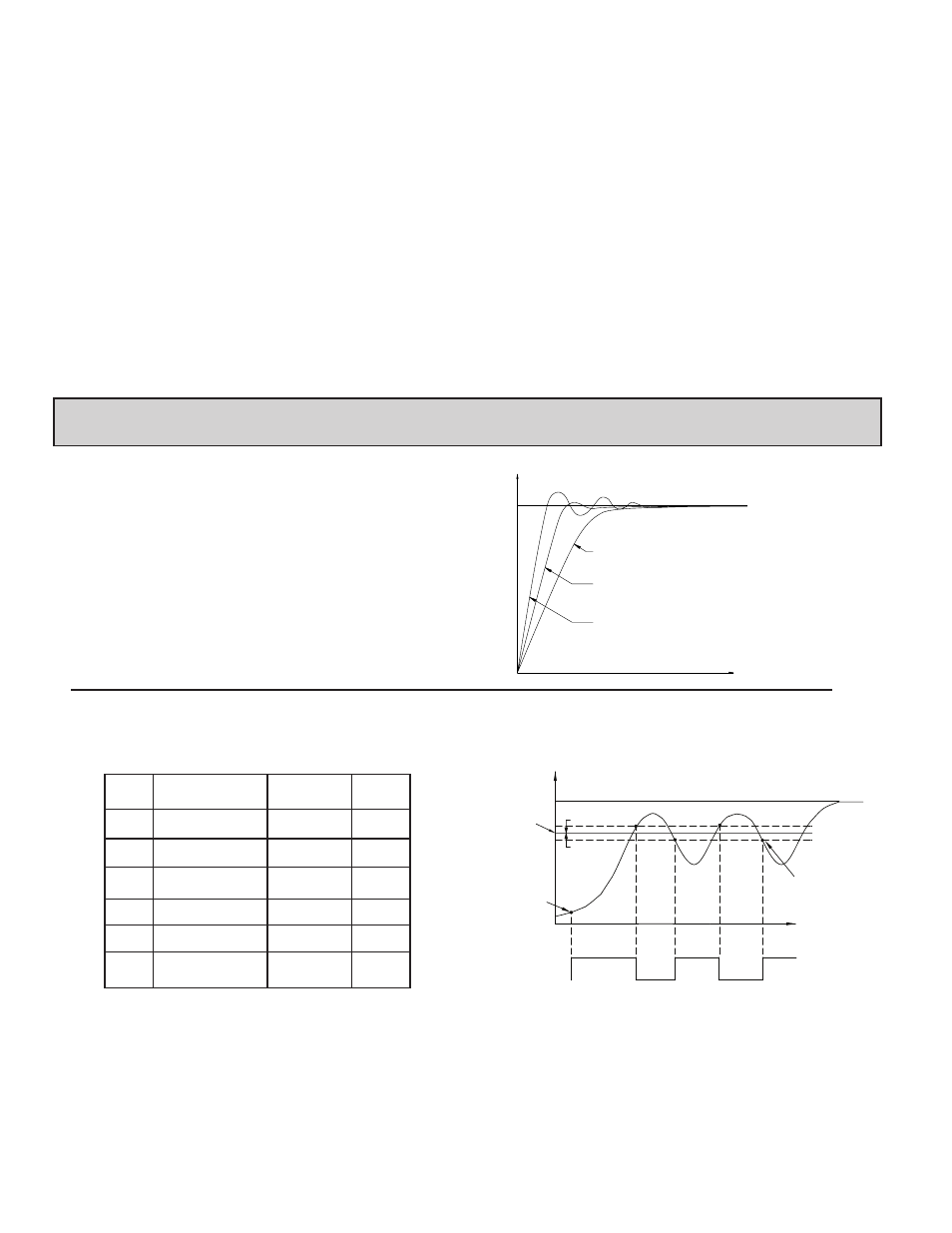

TIME

INPUT

TYPICAL RESPONSE CURVES WITH

AUTO-TUNE CODES 0 TO 2.

SP

0

1

2

AUTO-TUNE CODE FIGURE

Start Auto-Tune

Below are the parameters and factory settings that affect Auto-Tune. If these

setting are acceptable then Auto-Tune can be started just by performing two

steps. If changes are needed, then they must be made before starting Auto-Tune.

1. Enter the Setpoint value in the Display Loop.

2. Initiate Auto-Tune by changing Auto-Tune Start to in the Hidden

Loop.

Auto-Tune Progress

The controller will oscillate the controlling output(s) for four cycles. The

bottom display will flash the cycle phase number. Parameter viewing is

permitted during Auto-Tune. The time to complete the Auto-Tune cycles is

process dependent. The controller should automatically stop Auto-Tune and

store the calculated values when the four cycles are complete. If the controller

remains in Auto-Tune unusually long, there may be a process problem. Auto-

Tune may be stopped by entering in Auto-Tune Start .

TIME

INPUT

Aut1

Aut4

AUTO-TUNE

START

AUTO-TUNE

CONTROL

POINT

SETPOINT

AUTO-TUNE COMPLETE, PID

SETTINGS ARE CALCULATED

AND LOADED INTO MEMORY

Aut2

Aut3

ON

OFF

ON

OFF

OUTPUT 1 (O1) :

PHASE

1/2 CHYS *

1/2 CHYS *

* - On/Off Control Hysteresis

AUTO-TUNE OPERATION

(REVERSE ACTING)

DISPLAY

PARAMETER

FACTORY

SETTING

MODULE

Input Type

T16

P16

1I

F

Digital Filtering

1

1I

On/Off Control

Hysteresis

2

T16

2

P16

2

Auto-Tune Code

2

2

Deadband

2

n

Auto-Tune Access