Roubleshooting – Red Lion P16 User Manual

Page 20

20

RESTORE FACTORY SETTINGS

Press and hold B to display . Press A. The controller will display

and then return to F. Press L to return to the Display Loop. This will

overwrite all user settings with Factory Settings.

NOMINAL CALIBRATION SETTINGS

Press and hold B to display . Press A. Press and hold B to display

again. Press A. The controller will then return to F. Press L to

return to the Display Loop. This will not overwrite any user settings but will

erase the controller calibration values. This procedure does not require any

calibration signals nor external meters. This can be used to clear calibration

error flag .

CAUTION: This procedure will result in up to ±10% reading error and the

controller will no longer be within factory specifications. For this reason, this

procedure should only be performed if meter error is outside of this range to

temporarily restore operation until the unit can be accurately calibrated.

For further technical assistance, contact technical support.

t

roubleShooting

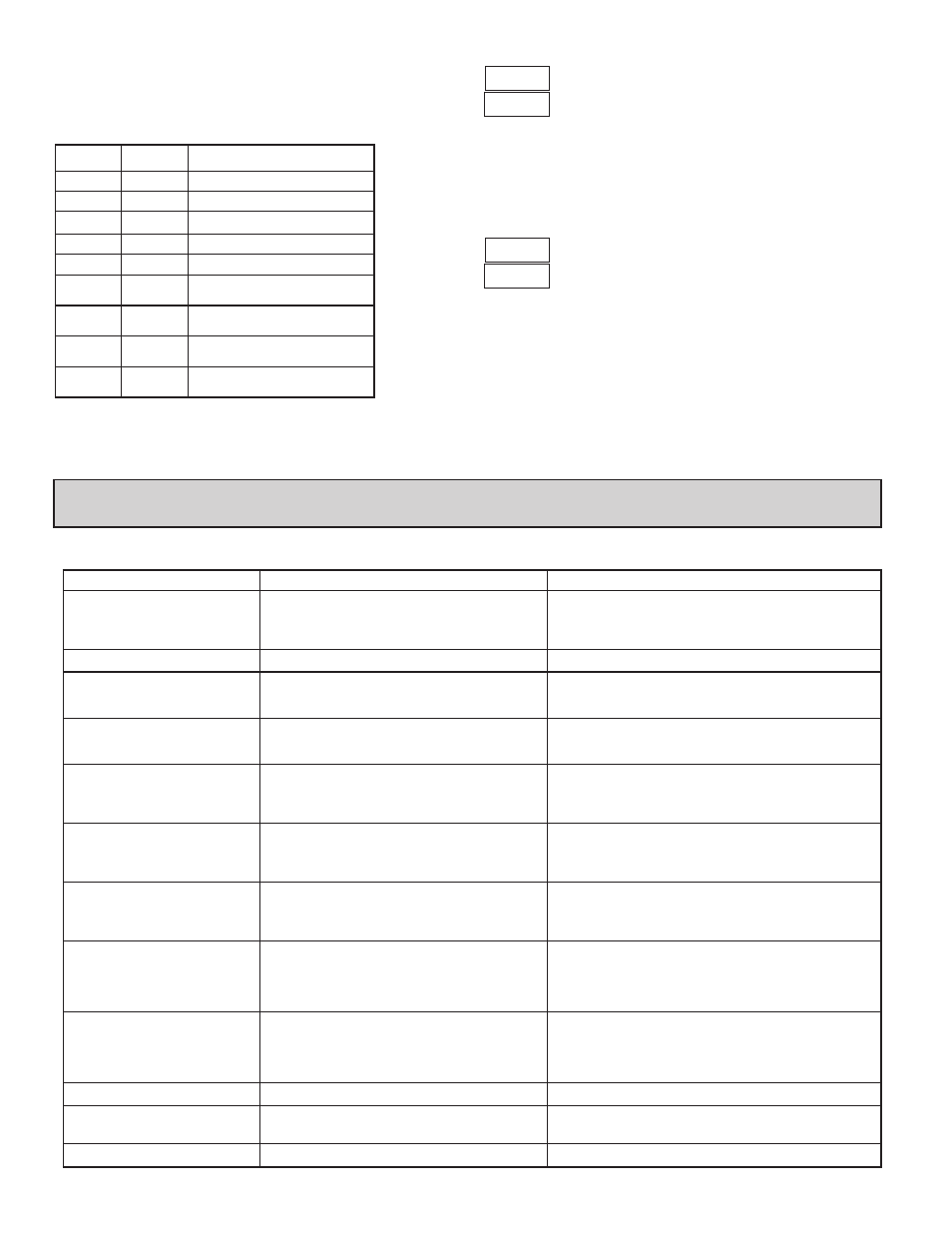

Analog Output Calibration (T16 and P16)

Set the controller Analog jumpers to the output type being calibrated.

Connect an external meter with an accuracy of 0.05% (or better) that is capable

of measuring 10.00 V or 20.00 mA to terminals 6 (+V/I) and 7 (-V/I). The

voltage or current calibration that is not being used must be skipped by pressing

A

until End appears.

PROMPT

EXTERNAL

METER

FRONT PANEL ACTION

Press J until

, press A.

Press A.

Press A. (T16 only)

Press A. (T16 only)

Press B for

, press A.

0.00 V

Press B or J until external meter

matches listing, press A.

1

10.00 V

Press B or J until external meter

matches listing, press A.

0.0 mA

Press B or J until external meter

matches listing, press A.

2

20.0 mA

Press B or J until external meter

matches listing, press A.

PROBLEM

CAUSE

REMEDIES

NO DISPLAY

1. Power off.

2. Brown-out condition.

3. Loose connection or improperly wired.

4. Bezel assembly not fully seated into rear of controller.

1. Check power.

2. Verify power reading.

3. Check connections.

4. Check installation.

CONTROLLER NOT WORKING

1. Incorrect setup parameters.

1. Check setup parameters.

2

IN DISPLAY

1. Loss of setup parameters due to noise spike or other

EMI event.

1. Press F1 to escape, then check controller accuracy.

a. Recalibrate controller. (See Factory Service Module code 77.)

b. Reset parameters to factory default settings.

IN DISPLAY

1. Loss of calibration parameters due to noise spike or

other EMI event.

1. Press F1 to escape, then check controller accuracy.

a. Recalibrate controller. (See Factory Service Module code 77.)

b. Reset parameters to factory default settings.

or

IN DISPLAY

1. Display value exceeds 4 digit display range.

2. Defective or miscalibrated cold junction circuit.

3. Loss of setup parameters.

4. Internal malfunction.

1. Press F1 to escape, then check controller accuracy.

a. Recalibrate controller. (See Factory Service Module code 77.)

b. Reset parameters to factory default settings.

IN DISPLAY (T16)

1. Probe disconnected.

2. Broken or burned-out probe.

3. Corroded or broken terminations.

4. Excessive process temperature.

1. Change resolution to display whole number and verify reading.

2. Perform cold junction calibration.

3. Check setup parameters.

4. Perform Input calibration.

IN DISPLAY (P16)

1. Input exceeds range of controller.

2. Incorrect input wiring.

3. Defective transmitter.

4. Internal malfunction.

1. Check input parameters.

2. Check input wiring.

3. Replace transmitter.

4. Perform input calibration.

IN TOP DISPLAY

1. Input exceeds range of controller.

2. Temperature exceeds range of input probe.

3. Defective or incorrect transmitter or probe.

4. Excessive high temperature for probe.

5. Loss of setup parameters.

1. Check input parameters.

2. Change to input sensor with a higher temperature range.

3. Replace transmitter or probe.

4. Reduce temperature.

5. Perform input calibration.

IN TOP DISPLAY

1. Input is below range of controller.

2. Temperature below range of input probe.

3. Defective or incorrect transmitter or probe.

4. Excessive low temperature for probe.

5. Loss of setup parameters.

1. Check input parameters.

2. Change to input sensor with a lower temperature range.

3. Replace transmitter or probe.

4. Raise temperature.

5. Perform input calibration.

IN DISPLAY (T16)

1. RTD probe shorted.

1. Check wiring and/or replace RTD probe.

CONTROLLER SLUGGISH OR

NOT STABLE

1. Incorrect PID values.

2. Incorrect probe location.

1. See PID control.

2. Evaluate probe location.

IN DISPLAY

1. Control output is damaged.

1. Return controller to factory for repair.