Etting, Umpers, Nstalling – Red Lion P16 User Manual

Page 5: Ontroller, Multiple controller stacking, Nalog, Utput, Odels

5

1.0 S

etting

the

J

umperS

(A

nAlog

o

utput

m

odelS

o

nly

)

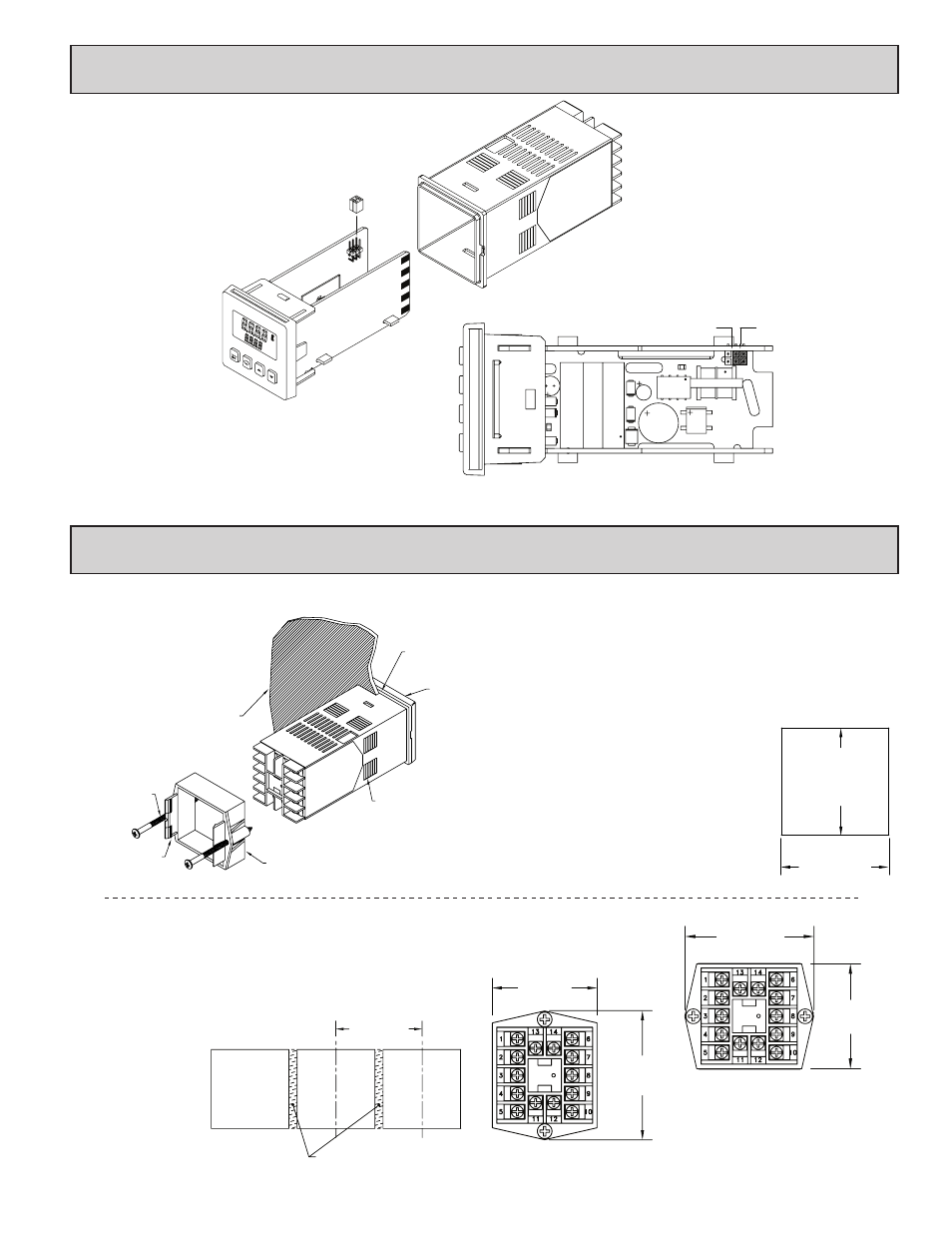

To insure proper operation, the Analog Output jumpers must be set to the same

range selected in programming Module 2-OP. The default jumper setting

is for 20 mA. The default setting in Module 2-OP is 4-20 mA. To

access the jumpers, insert a flat-blade screwdriver between the front

panel and the side case slot. This should disengage the top and

bottom front panel latches from the case grooves. Pull the

front panel assembly with the controller boards out of

the case. The jumpers are located inside the

controller on the left board along the back

top section.

20mA (Both jumpers toward

the rear of the unit)

10V (Both jumpers toward

the front of the unit)

VIEW FROM TOP OF UNIT

02

F1

RDY

A2

01

A1

°

%PW

MAN

%

YORK

, PA

. M

ADE

IN U

.S.A.

RED LION C

ONTROLS

2.0 i

nStAlling

the

C

ontroller

Instructions:

1. Prepare the panel cutout to the proper dimensions.

2. Remove the panel latch from the controller. Discard the cardboard sleeve.

3. Carefully remove the center section of the panel gasket and discard. Slide the

panel gasket over the rear of the controller, seating it against the lip at the

front of the case.

4. Insert the controller into the panel cutout. While holding the controller in

place, push the panel latch over the rear of the controller, engaging the tabs

of the panel latch in the farthest forward slot possible.

5. To achieve a proper seal, tighten the panel latch

screws evenly until the controller is snug in the

panel, torquing the screws to approximately 7

in-lb (79 N-cm). Overtightening can result in

distortion of the controller, and reduce the

effectiveness of the seal.

Note: The installation location of the controller is

important. Be sure to keep it away from heat

sources (ovens, furnaces, etc.) and away from

direct contact with caustic vapors, oils, steam, or

any other process by-products in which exposure

may affect proper operation.

-0.0

+0.6

-0.000

+0.024

-0.0

+0.6

-0.000

+0.024

(45 )

1.772

(45 )

1.772

14

13

6

7

8

10

9

LATCHING

BEZEL

LATCHING

PANEL LATCH

PANEL

MOUNTING

SCREW

TABS

SLOTS

PANEL

PANEL GASKET

Multiple Controller Stacking

The controller is designed to allow for close spacing of multiple controllers

in applications that do not require protection to NEMA 4X. Controllers can be

stacked either horizontally or vertically. For vertical stacking, install the panel

latch with the screws to the sides of the controller. For horizontal stacking, the

panel latch screws should be at the top and bottom of the controller. The

minimum spacing from centerline to centerline of controllers is 1.96" (49.8

mm). This spacing is the

same for vertical or

horizontal stacking.

Note: When stacking

controllers, provide

adequate panel

ventilation to ensure

that the maximum

operating temperature

range is not exceeded.

1.96 (49.8)

MIN

STANDARD

PANEL

CUT-OUT

IF NEMA 4 IS NOT REQUIRED,

THIS PANEL MATERIAL MAY BE REMOVED.

2.39 (60.7)

MAX.

1.96 (49.8)

MAX.

2.39 (60.7)

1.96 (49.8)

MAX

MAX

The T16 and P16 controllers meet NEMA 4X/IP65 requirements for indoor

use to provide a watertight seal in steel panels with a minimum thickness of

0.09", or aluminum panels with a

minimum thickness of 0.12". The

controllers are designed to be

mounted into an enclosed panel.

The bezel assembly must be in

place during installation of

the controller.