Troubleshooting and maintenance – AMT Datasouth 600 User Manual

Page 46

44

User Manual

TROUBLESHOOTING AND MAINTENANCE

When the printer detects a malfunction or an abnormal condition occurs the READY LED

will begin to blink. The printer will also stop printing and communication with the host will

stop.

Check the following LED conditions when the READY LED is blinking.

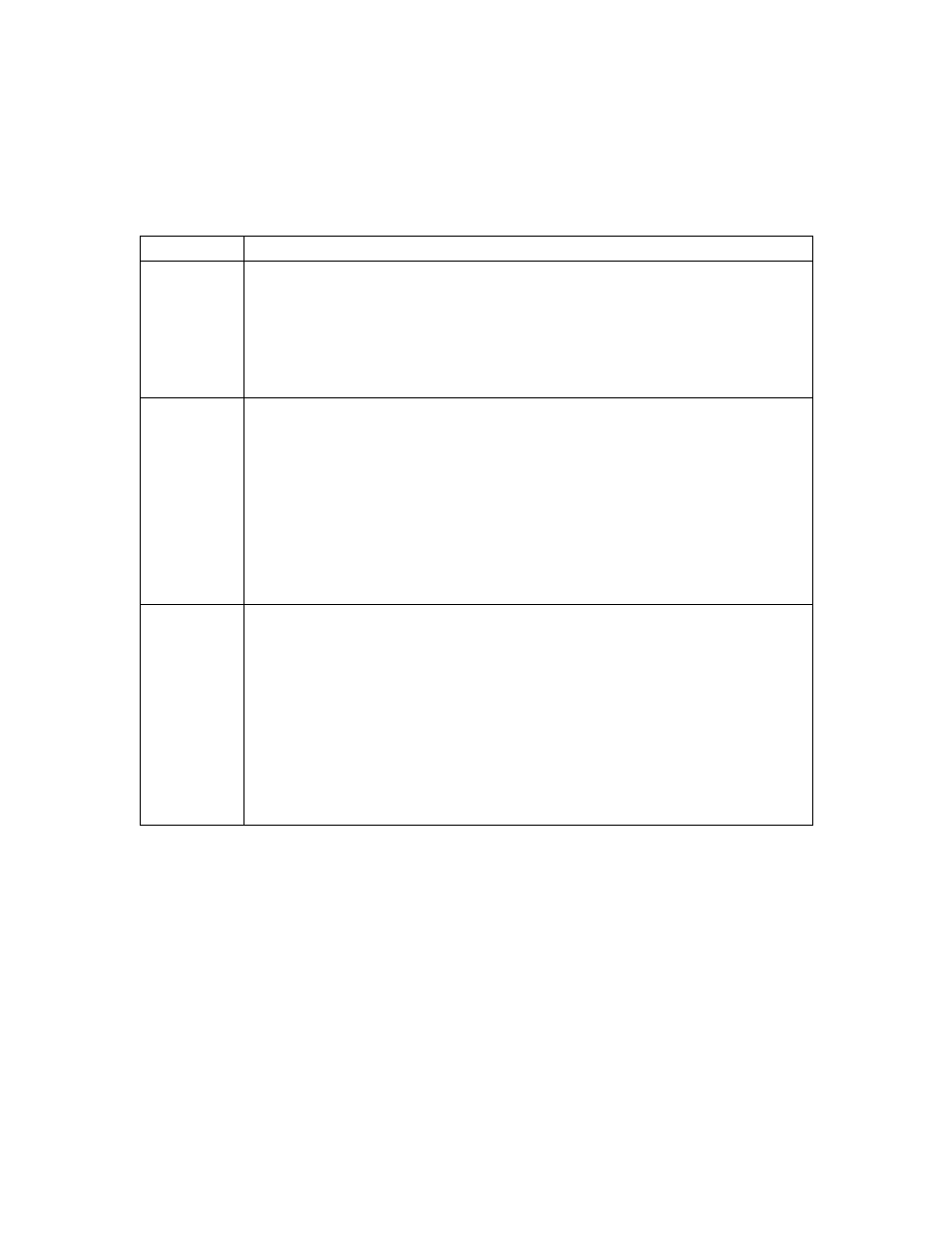

LED

Error Condition and possible Cause and Correction

m READY

Blinking:

Ø

The format or baud rate of the RS232 protocol is incorrect between the

printer and host.

Ø

The cutter can not cut off the media, check the media and cutter.

Ø

The printer buffer is full. Can be caused by the loaded soft fonts, graphics

or forms.

m MEDIA

Blinking: Media Error. A reflective sensor under the media stock monitors the

media. If the media sensor does not see the media stock or if the next

Top-of-Label is not at the expected location or if the back of the

media stock absorbs the reflection this error may occur.

Ø

Typically a Media OUT has occurred. Install a new media.

Ø

Verify that Media Sensor is in proper position.

Ø

Verify that a foreign substance does not cover the Media Sensor slot.

Ø

Verify that the media stock have dark information printed on the back.

Ø

Calibrate the printer.

m RIBBON Blinking: Ribbon error occurred. The printer monitors the motion of the Supply

roll. If the printer is set for Thermal Transfer and the Supply Roll

does not turn, then a ribbon error will occur.

Ø

Typically the ribbon is out. Install a new ribbon.

Ø

Ribbon has broken. Verify that the Heat and the Print Speed settings do

not result in burning the ribbon in two. Also, very large black lines that are

full length of the media may also cause the ribbon to separate.

Ø

Does the Ribbon Supply and Ribbon Take-up Cores have notches on the

left side of the core. If not then use the adapter cores.

Ø

Verify that the ribbon is being pulled by the Take-up roll.