JKS 9100 User Manual

Page 4

JKS9100

JKS Switchblade Swaybar Installation

4 Page

and 3/16” punch are useful for driving the locking

pin into position.

With pin installed, fill the rest of the through-hole

with blue RTV silicone. Do this on front and back

of indexing head. This step is important – do not

skip. Silicone will seal through-hole from both ends

to prevent any moisture or debris from entering.

Repeat this process to install the second Blade

Arm Assembly (B), making sure both arms are

perfectly aligned before installing pin.

HINT: If

arms are not aligned, remove the second arm and

rotate up or down by one spline until arms are

mounted on the exact same plane.

Blade Arms must be perfectly aligned with each other

before proceeding.

6. PREPARE END LINKS

To ensure proper swaybar operation, the supplied End

Links must be adjusted to the appropriate length for your

application. Adhere to the following instructions carefully to

determine the correct process for your vehicle.

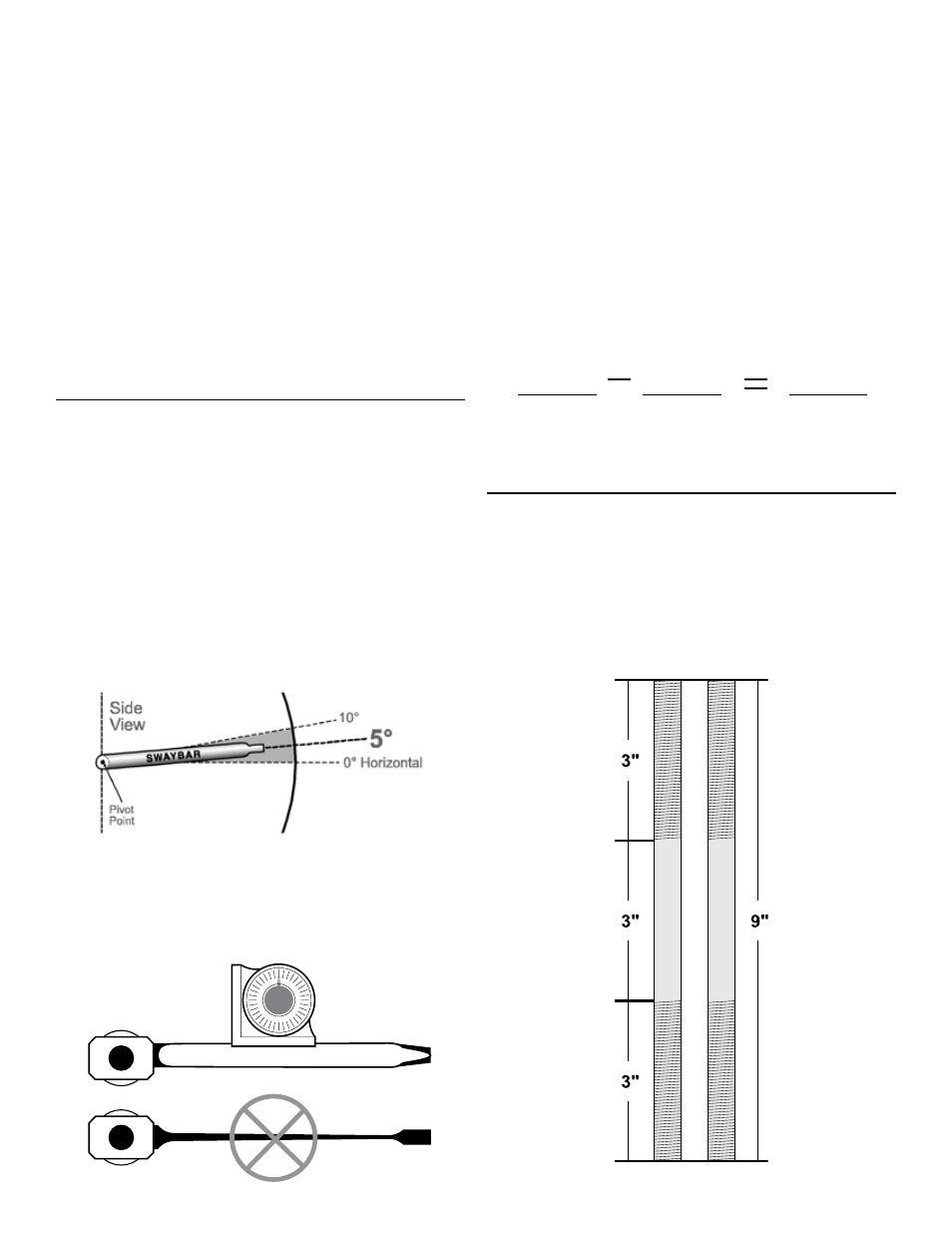

With the vehicle at normal ride height and located

on level ground, pivot the Blade Arms (A & B) until

they are level or parallel (within 2.5 degrees) with

the ground as illustrated below.

HINT: An angle

measuring tool placed directly on the Blade Arm is

useful for verifying angle. Always measure blade

arm in vertical position to ensure taper in horizon-

tal position does not affect results.

Rotate the Blade Arms (A & B) to the proper angle

and hold them in position.

HINT: A board, length of

pipe, or similar object clamped to one Blade Arm

is useful for holding in position.

While holding the Blade Arms (A & B) at the proper

angle, measure the distance between the center

of the hole at the end of each Blade Arm and the

original swaybar link mounting holes on the axle

bracket.

Subtract 3" from the distance recorded above to

determine the modified length of the Connecting

Rod (H).

HINT: For instance, if the center-to-center

distance for your application is 10", the modified

Connecting Rod length should be 7"

Distance between

mounting ends

Connecting Rod

(modified length)

3"

7. mODIFY CONNECTING ROD

The supplied Connecting Rods (H) are long enough to

accommodate an infinite range of lift heights. On most

applications, they must be shortened to set the swaybar at

the proper angle. This is accomplished by removing excess

material from the Connecting Rods, based on the modified

length measurement (from previous step) and the instruc-

tions that follow.