JKS 9100 User Manual

Page 3

JKS9100

JKS Switchblade Swaybar Installation

Page 3

Remove front swaybar from vehicle.

3. PREPARE FRONT CROSS mEmBER

The SwitchBlade Swaybar mounts through the tubular

crossmember that connects the chassis rails together im-

mediately forward of the steering box. Crossmember must

be intact and free of damage in order to install this product.

Inspect the inside surface at each end of the

crossmember for any debris or deformation that

could interfere with installation of Torsion Bar

Bushings (D).

Clean any mud, dirt, rust, burs, slag, or other de-

bris from inside ends of crossmember.

HINT: A die grinder with sanding wheel or similar tool is

useful for removing stubborn debris.

4. INSTALL TORSION BAR

Insert a Torsion Bar Bushing (D) into each end of

the tubular crossmember.

HINT: A block of wood

and soft mallet may be useful to fully seat bushing

into crossmember. Do not use brute force – only

light tapping with mallet. A light application of

silicone lubricant to outer surface of bushing may

also be used. If bushings are still difficult to insert,

contact JKS at 877-533-7557 for technical assis-

tance.

Wipe down the Torsion Bar (C) with a light applica-

tion of Silicone lubricant.

Install Torsion Bar (C) by guiding it through the

Torsion Bar Bushings (D) until it is centered.

CROSS MEMBER

CHASSIS

RAIL

BUSHING

TORSION BAR

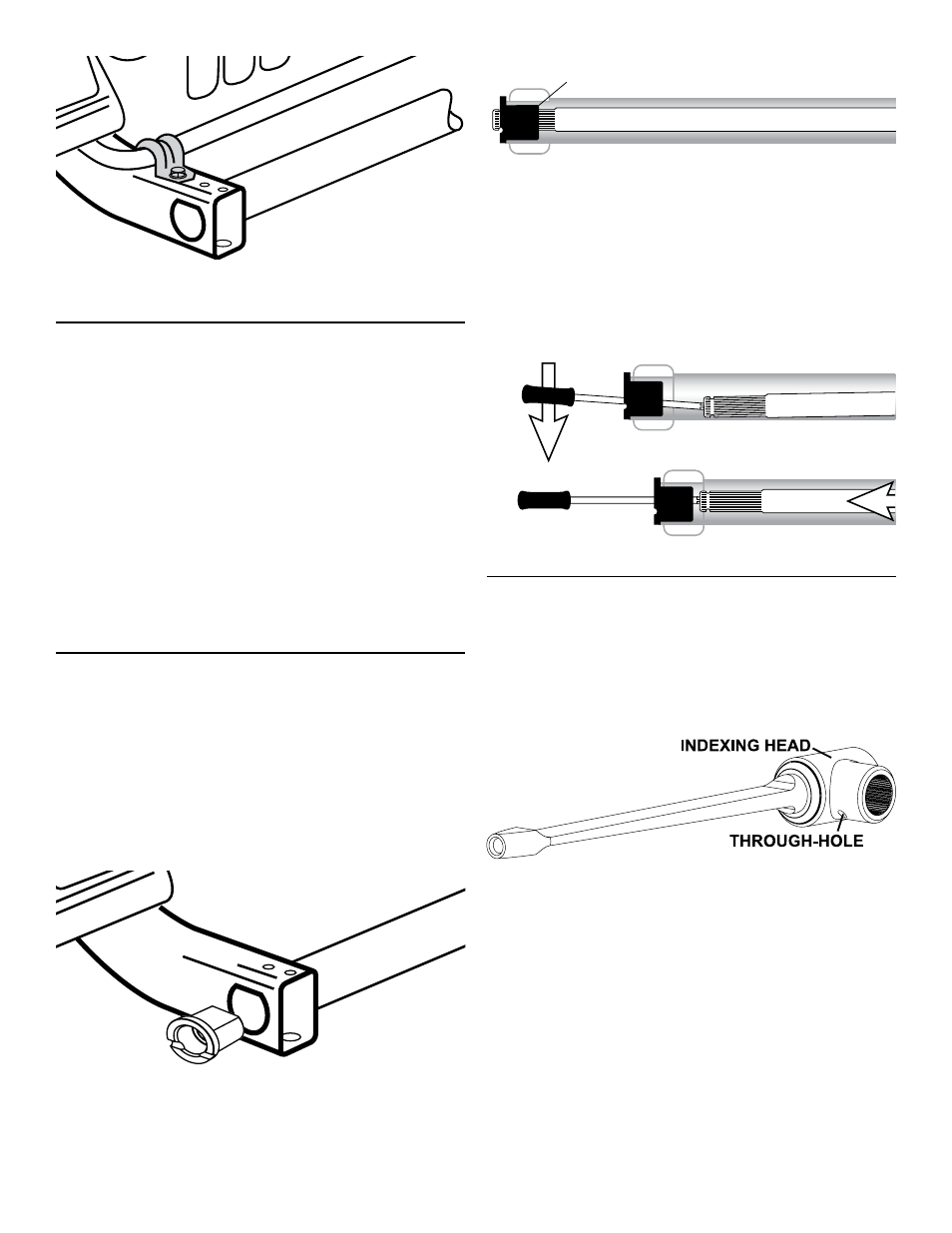

HINT: To guide torsion bar through bushing at far end of

crossmember, insert a Philips head screwdriver through

bushing and into center hole of torsion bar as illustrated

below. Pry torsion bar up using screwdriver while pushing

it through the bushing from the opposite end.

Use caution to avoid damaging bushings when install-

ing torsion bar.

CROSS MEMBER

CHASSIS

RAIL

BUSHING

TORSION BAR

CROSS MEMBER

CHASSIS

RAIL

BUSHING

TORSION BAR

5. INSTALL BLADE ARmS

Locate the Blade Arm Assemblies (A & B) and

identify their correct mounting location by read-

ing the label applied to the Indexing Heads. “RH”

indicates Right-Hand side, and “LH” indicates Left-

Hand side.

Hint: When installed correctly, the 1/4”

through-hole will be on bottom of Indexing Head.

BLADE ARM ASSEMBLY

Slide the splined opening of the Indexing Head on

to end of Torsion Bar (C).

HINT: It may be neces-

sary to gently tap side of Indexing Head with a

rubber mallet to fully engage splines. Use a clean,

soft towel to protect the polished finish.

Slowly pivot the Blade Arm Assembly (A) up or

down until the 1/4” through-hole in Indexing Head

aligns with the access groove in the Torsion Bar

Bushing (D) as illustrated below.

Insert a 1/4" Dowel Pin (E) into the through-hole as

shown below.

Drive the 1/4” Dowel Pin (E) into through-hole until

it is centered as shown below.

HINT: A hammer