JKS 2710 User Manual

Installation instructions

JKS ACOS Pro

™

Installation

PN 2710

Page 1 of 5

Installation

Instructions

Product:

ACOS Pro™

Part Number: PN 2710

Application: Jeep Wrangler JK, 2007+ (front only)

Welcome

CONGRATULATIONS on your purchase

of a new JKS ACOS Pro

™ system! At JKS

Manufacturing, we are committed to providing

you with the best products available and your

satisfaction is our first priority.

PLEASE READ these Installation Instructions

carefully, and save them for future reference,

as they contain important installation and

maintenance information.

Before You Begin…

1. Familiarize yourself with the supplied parts

as illustrated in the column to the far right.

2. Thoroughly read all procedures to ensure

you have the tools and experience

necessary to complete this installation.

3. If you are not completely comfortable with

any of the procedures described on the

following pages, do not attempt this

installation. Contact the JKS Technical

Department at (308) 762-6949 to locate a

qualified installation specialist in your area.

Important

MOST VEHICLES REQUIRE additional parts

or modifications to accommodate the

immediate increase in ride height provided by

the ACOS Pro

™ system.

DO NOT EXCEED maximum range of

adjustment

– see illustration on page 3.

NOT COMPATIBLE with Rancho, TrailMaster,

Rough Country or Fabtech coil springs.

INSTALLATION of this product is not

reversible and should only be performed by an

experienced mechanic or fabricator.

Tools Required

Hydraulic Floor Jack and Jack Stands

Metric/Standard Socket Wrench Set

1/4” Allen Wrench

Die Grinder with Cut-Off Wheel

(or reciprocating saw)

File or Deburring Tool

Emory Cloth (or similar paint stripping tool)

Rubber or Plastic Mallet *

Tape Measure

Spray Lubricant (WD-40 or similar)

Anti-Seize Lubricant

Medium Strength Threadlocker

Satin Black Spray Paint

Welding Equipment

Band Saw (or equivalent) *

16TPI Thread Restoring File (or equivalent) *

Coil Spring Compressor *

Factory Service Manual (recommended)

* Asterisk denotes tools that are not required for some

applications. Thoroughly read instructions first to

determine which tools will be required for your

application.

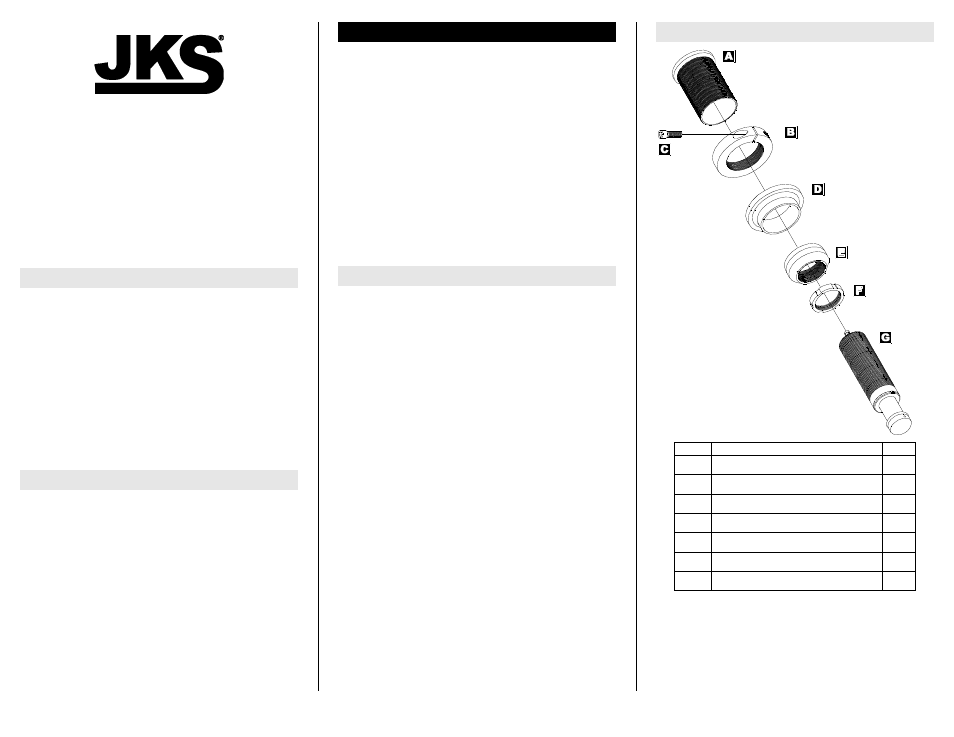

Parts

DESCRIPTION

QTY

A Threaded Tube

2

B Adjuster Ring

2

C 5/16” x 1-1/4” Cap Bolt

2

D Isolator Pad

2

E Bump Shock Adapter

2

F Bump Shock Nut

2

G Bump Shock Assembly

2