JKS OGS166 User Manual

Page 6

JKSOGS166

JKS Front Trackbar + Sector Shaft Reinforcement Installation

6 Page

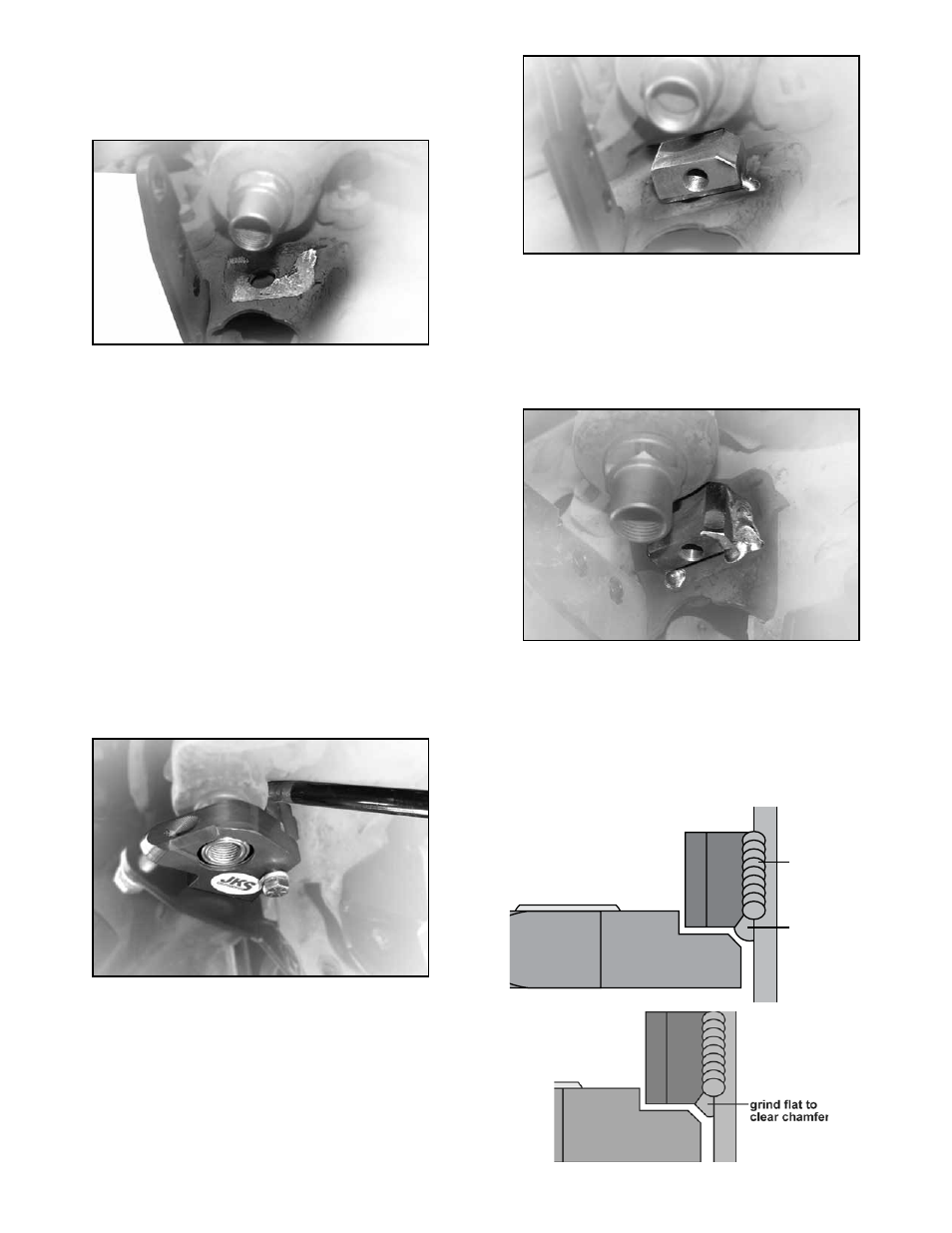

Remove paint from area on chassis where edges

of Pillow Block Frame Mount (I) are marked.

HINT:

If you cannot reach the area with a sanding tool, a

piece of emory cloth or sandpaper may be useful.

With bare metal exposed on chassis, the Steer-

ing Sector Pillow Block (E) must be re-installed so

that the Pillow Block Frame Mount (I) can be tack

welded in place. Slide the Pillow Block assembly

back onto the Sector Bearing Nut (G) and re-insert

the two 3/8” Bolts (L) and 1/2” Bolt (U) to hold the

Pillow Block in position.

Re-adjust the Steering Sector Pillow Block (E) until

level side-to-side and square to Trackbar Chassis

Bracket (A) as before.

Once the Pillow Block is properly positioned, add

tension to the two 3/8” Bolts (L) and 1/2” Bolt (U)

until snug to prevent the Pillow Block from acci-

dentally moving.

With mounting bolts snug, make sure the Pillow

Block Frame Mount (I) is square to Pillow Block

and positioned as close to chassis as possible.

Remember, a small gap between the weld-on

mount and chassis is normal and acceptable.

While holding the Frame Mount (I) in place, care-

fully tack weld both sides of the weld-on mount

directly to the chassis.

HINT: It may be helpful to

apply slight pressure from above using a pry bar to

ensure Frame Mount remains flush against Pillow

Block.

Once the Frame Mount (I) is securely tacked in the

desired position, remove the two 3/8” Bolts and

1/2” Bolt and slide the Sector Shaft Pillow Block off

of the Sector Bearing Nut.

Make sure you can access both sides of Frame

Mount (I) with welder. If necessary, the Trackbar

Chassis Bracket (A), Sector Bearing Nut (G) and/or

pitman arm can be temporarily removed for better

accessibility.

Completely weld both sides of Pillow Block Frame

Mount (I) to chassis.

Bottom of Frame Mount may also be welded to

chassis as long as bead does not interfere with

re-installation of Pillow Block.

HINT: Edges of

weld-on mount and Pillow Block are chamfered

to provide clearance for small weld bead. If weld

bead interferes with re-installation of Pillow Block,

you must remove any protrusions using a grinding

wheel for proper fitment.

horizontal

weld (bottom)

vertical

weld (side)

chassis