Setra System Model 869 User Manual

Page 12

12

6.0 POCKET PC INTERFACE SCREENS

The Pocket PC Interface is tab-based, split into 6 major sections at the

bottom of the screen.

6.1 APPLICATION DEFINITIONS

General: This describes operation for the broadest range of applications.

Dial Gauge: Departures from general operation for Dial Gauge calibration.

P-Switch: Departures from general operation for Pressure Switch calibration.

Expert System: Departures from general operation for Expert System

calibration.

6.2 REAL TIME: General

Screen Instructions (Diagram 7):

Real Time page is constantly updating and is used to see the output and

pressure being applied for calibration purposes and test purposes (acts as

a digital indicator).

Applied Pressure Window: Displays system pressure. When “Go To

Pres.” is pushed, the text will turn yellow while pressure is outside of tar-

get control band. (Required control stability for UUT.) Text will turn green

when target pressure is reached.

Go to Pressure macro buttons are configured by UUT pressure range.

For all units, the top most button will display the UUT’s lowest Input Pres-

sure. The bottom-most button will display the UUT’s highest input pres-

sure. The middle button will display “0.0” for bidirectional units, and 50%

FS (Full Scale) of UUT range for unidirectional units.

Pressing any of the buttons enters the pressure value on the button into

the target pressure window and calls the “Go to Pressure” function.

HOLD SAMPLE: Will take a filtered reading and freeze the display with

that reading. To release, press the same button - Release Hold.

VENT: Opens both positive and negative pressure ports to each other

and atmosphere.

TARE: Zeros out internal pressure standard and re-zero’s mechanical

components in controller.

GO TO PRESSURE: Calls controller to generate pressure point set in

pressure target box.

HALT: Stops any process in action.

MONITOR/CONTROL: Switches calibrator into monitoring mode. This

allows calibrator to be used as pressure measurement device.

Error Graph is an auto-scaling display of the present error of the UUT’s

output as compared to the applied pressure. The red bars on the graph

represent the UUT’s accuracy specification limits. The labels will display

Excitation to Unit UnderTest (UUT)

Tares Internal Pressure Standard

Applied Pressure

UUT Output

Terminal Based

Error (%FS)

Includes Zero

and Span Errors

Bar Graph of

Error (%FS)

Snapshot of Any

Displayed Condition

Vents Pressure to Atmosphere

Halts Operation

Monitor Mode

Current Pressure Target

Go To Pressure Macro buttons

45

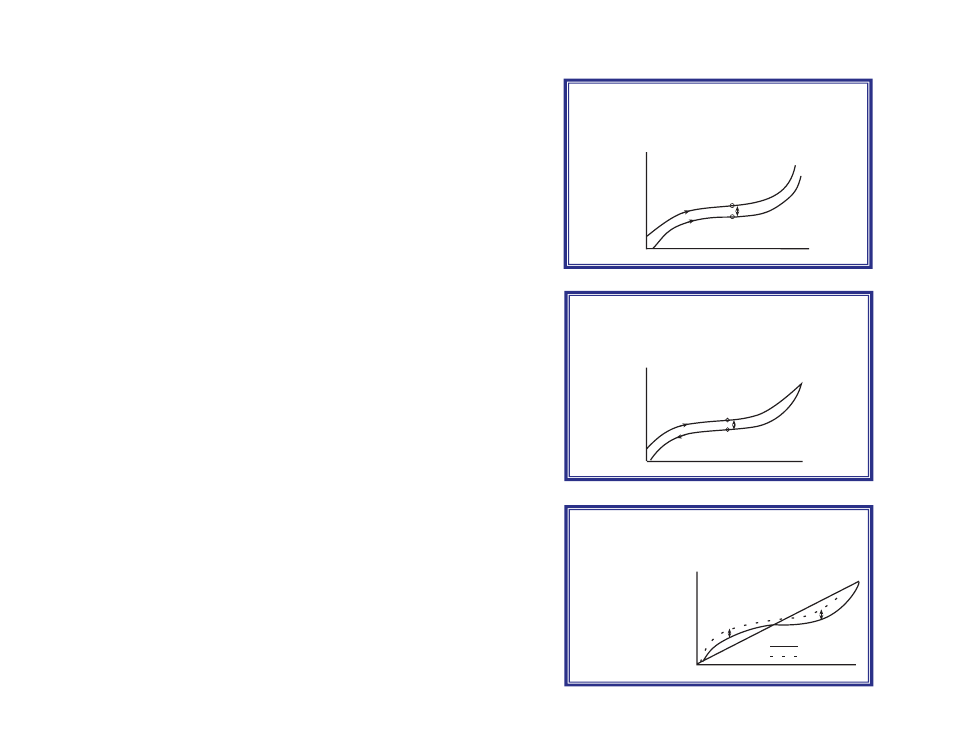

Hysteresis

Non-Repeatability

The ability of a transducer to reproduce output

readings when the same pressure value is

applied to it consecutively, under the same

conditions, and from the same direction.

5 VDC

0 VDC

0 PSI

100 PSI

<0.02%FS

The maximum difference in output at any

pressure value within the specified range, when

the value is approached with increasing and

decreasing pressure.

5 VDC

0 VDC

0 PSI

100 PSI

<0.05%FS

Long-Term Stability

The ability of a transducer to reproduce output

readings obtained during its original calibration

at room conditions for a specified period of time.

5 VDC

0 VDC

0 PSI

100 PSI

+0.1

% F

S

Example: ±0.1% FS

Over 6 Months at

70°F (21°C)

-0.1

% F

S

Original Calibration

After 6 Months