Setra System 260 User Manual

Installation guide, General information, Multi-sense range specifications

Installation Guide

“Multi-Sense” Model 260 Series

Multi-Range Differential Pressure Transducer

GENERAL INFORMATION

Every Model 260 has been calibrated and tested before shipment to guarantee

performance for all pressure ranges.

The Model 260 is available in four versions, which have field selectable range

capability via a slide switch. See four versions below:

MULTI-SENSE RANGE SPECIFICATIONS

The Model 260 is available in three field selectable output configurations. See three versions below:

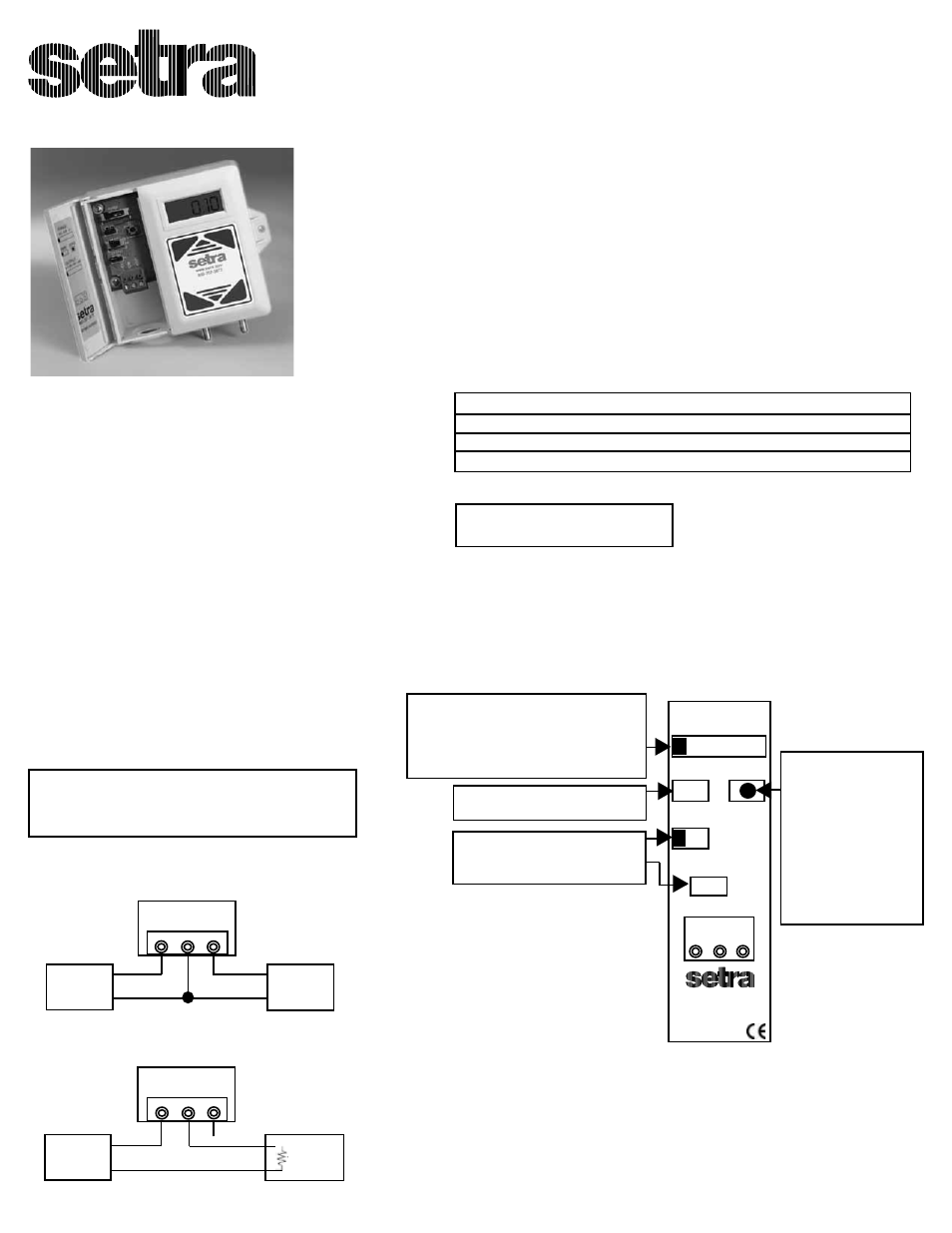

SIMPLE 5-STEP SETUP INSTRUCTIONS - STEPS 2 - 5

Power On - LCD Display

Display momentarily toggles thru all existing setup parameters on initial power

up. Pressure is normally indicated on display. Units are either in inches of water

column (WC) MS1 & MS2, or Pascal (Pa) MS3 & MS4.

Multi-Sense Voltage

3-Wire, 0-5, 0-10 VDC Configuration

Model 260

Multi-Sense Current

2-Wire, 4-20 mA Configuration

STEP 1: Wire and Power Up Unit - Follow diagrams

below for 2-wire and 3-wire configurations. After

completing wiring requirements - Apply power to

the Model 260.

SIMPLE 5-STEP SETUP INSTRUCTIONS -

STEP 1

For CE compliance a properly grounded shielding cable is

required.

ELECTRICAL CONNECTIONS

-

EXC

COM

OUT

Power

Supply

13 - 30V

-

24V AC/DC

Nominal

Excitation

-

Model C260

+

-

EXC

COM

OUT

+

-

24V (DC Only)

Nominal

Excitation

+

-

X

Typical 250 Ohm

Sense Resistor

for 1-5V Output

Measurement

Voltage

Monitor

Power

Supply

13 - 30V

Current

Monitor

Removable Terminal Block for Easy Wiring

MECHANICAL INSTALLATION

Mounting Position

Mount and calibrate in vertical position for quick and easy installation

on ducts, walls or ceilings and in control rooms.

Media Compatibility

Model 260 transducers are designed to be used with air or

nonconducting gases.

Use with liquids or corrosive gases will damage the unit.

Environment

The operating temperature limits of the 260 are as follows:

Operating Temperature 32°F to 122°F (0°C to 50°C)

Compensated Temperature Range 32°F to 122°F (0°C to 50°C)

Model MS1 0.1”, 0.25”, 0.5” and 1.0” W.C. FS +/- 0.1”, 0.25”, 0.5” and 1.0” W.C. FS

Model MS2 1.0”, 2.5”, 5.0” and 10” W.C. FS +/- 1.0”, 2.5”, 5.0” and 10” W.C. FS

Model MS3 25, 50, 100 and 250 Pa FS +/- 25, 50, 100 and 250 Pa FS

Model MS4 .25, .50, 1.00 and 2.5 kPa +/- .25, .50, 1.00 and 2.5 kPa

Ranges

Version Unidirectional Bidirectional

2-Wire 4-20 mA (Current)

3-Wire 0-5, or 0-10 VDC (Voltage)

+

+

+

+

+

RANGE:

1 0.5 0.25 0.1

UNI/BI

ZERO

mA/Volt

+ -

2601MS1

S/N:

EXC

COM

OUT

*STEP 2: Select Pressure Range: Set

appropriate full scale range using

the Slide Switch Multiplier. LCD

will momentarily indicate selected

range.

STEP 5: Push Button

Zero - While at

zero pressure

Press and hold

the Zero Push

Button for 5

seconds to auto-

matically reset

output to zero.

STEP 3: Select Unidirectional

or Bi-directional mode.

**STEP 4: Select Current (mA)

or Voltage 0-5, or

0-10 VDC output range.

*Step 2 will follow same

instructions for other inches of

water column and pascal

ranges.

* * Step 4 be sure to set mA/volt

switch to volt position if using

0 to 5 or 0 to 10V outputs

5V/10V

JUMPER

ZERO AND SPAN ADjUSTMENT*

The unit may be recalibrated in the field using the push button zero/span.

Zero Adjustment:

1. With unit at zero differential pressure, push zero button for 5 seconds. Units

output and display will update.

Span Adjustment:

2. Apply full scale pressure (Note: Full scale value of largest range.). Press and hold

zero button for 5 seconds. Units output and display will update.

*Zero and Span points must be within 10% of factory setting.

JUMPER

● ● ●

Date Code

● ● ●