Appendix – Dwyer TIC User Manual

Page 75

74

Appendix

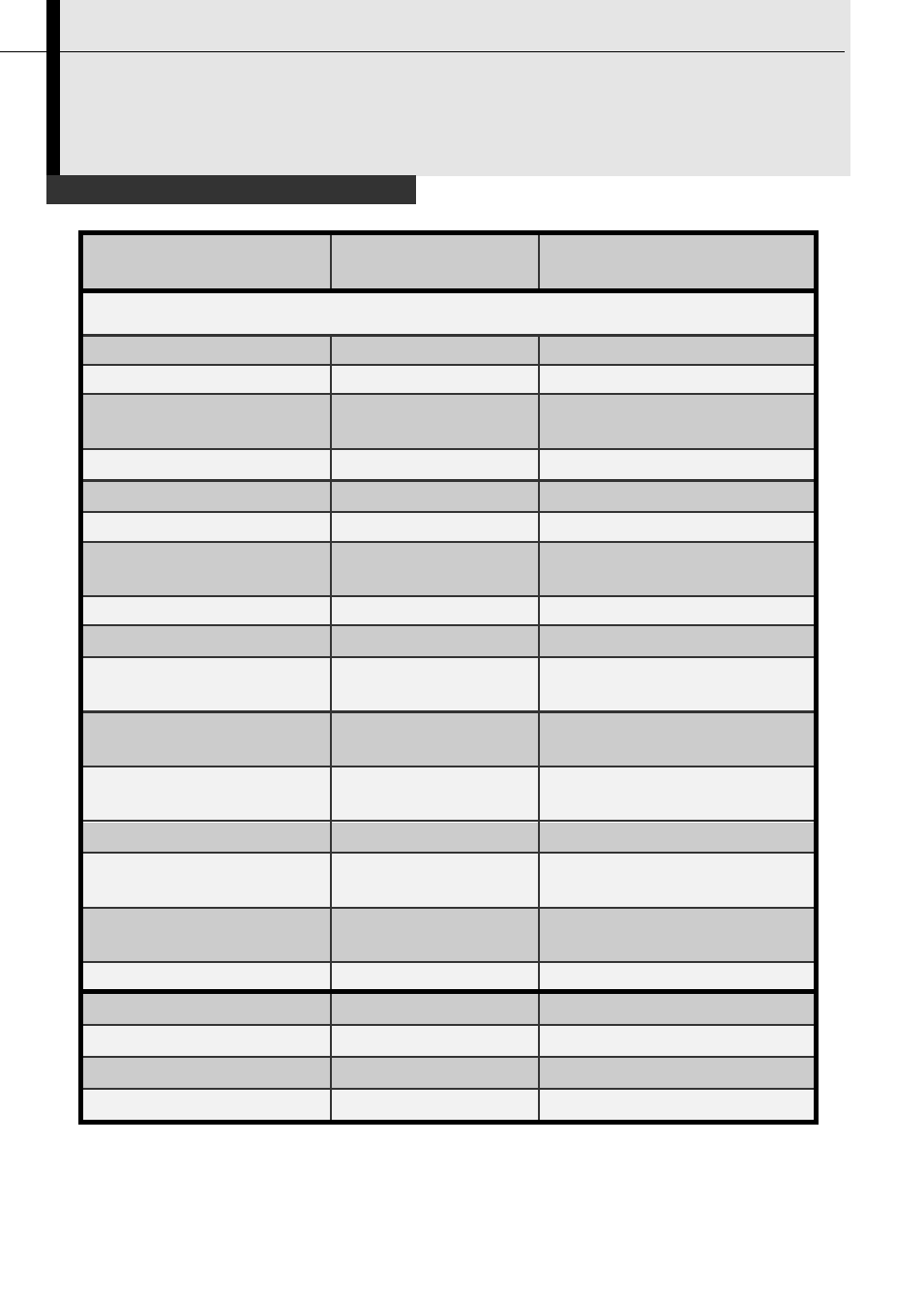

Emissivity table (continue)

Material

Temperature(°C)

Emissivity

approximation

Iron

Polished cast iron

200

0.21

Processed cast iron

20

0.44

Polished tempered

iron

40~250

0.28

Polished steel ingot

770~1040

0.52~0.56

Raw welded steel

945~1100

0.52~0.61

Surface ferric oxide

20

0.69

Completely rusty

surface

22

0.66

Rolled iron plate

100

0.74

Oxidized steel

198~600

0.64~0.78

Cast iron (Oxidizing at

600°C )

198~600

0.79

Steel (Oxidizing at

600°C )

125~520

0.78~0.82

Electrolytic ferric

oxide

500~1200

0.85~0.89

Iron plate

925~1120

0.87~0.95

Cast iron, heavy ferric

oxide

25

0.80

Tempered iron, ferric

oxide

40~250

0.95

Melting surface

22

0.94

Melting cast iron

1300~1400

0.29

Melting mild steel

1600~1800

0.28

Liquid steel

1500~1650

0.42~0.53

Pure liquid iron

1515~1680

0.42~0.45

- DPMX (2 pages)

- DPMP-4 (2 pages)

- DPMP-5 (2 pages)

- DPML-4 (2 pages)

- DPML-5 (2 pages)

- DPMW (2 pages)

- MPM (36 pages)

- SPPM-HSG (1 page)

- SPPM (4 pages)

- SPPM-C (4 pages)

- A-SPPM-TC (2 pages)

- ULB (18 pages)

- CRF2 (4 pages)

- CLT (2 pages)

- PBLT2 (1 page)

- PBLTX (4 pages)

- SBLT2 (1 page)

- SBLTX (4 pages)

- MBLT (2 pages)

- FBLT (2 pages)

- ULT (8 pages)

- UTC (20 pages)

- ULTM (20 pages)

- ULSL (30 pages)

- 1500 (16 pages)

- 2600 (52 pages)

- 2500 (16 pages)

- 16A (1 page)

- 16A (44 pages)

- 1600 (36 pages)

- 1600 (8 pages)

- 8600 (40 pages)

- 8C (6 pages)

- 32B (32 pages)

- SCZ10 (20 pages)

- 8C (24 pages)

- 32A (36 pages)

- 32DZ (40 pages)

- SCD (10 pages)

- SCD-PS (2 pages)

- SCD-8 (2 pages)

- SCD-LED (2 pages)

- 650 (2 pages)

- 651 (2 pages)

- 659RTD (2 pages)