Dwyer 659RTD User Manual

Push button pt100 temperature transmitter, Power supply u - + load pt 100

659RTD-1 User Guide

1.0

DESCRIPTION

The head mounted 659RTD-1 connects to any standard Pt100 resistance sensor and

converts the linearised temperature to a 4 to 20 mA signal. The transmitter is a two wire

device, and is fully configurable by the user, over a wide temperature range, with the aid

of a simple push button. This new design incorporates additional configuration menus,

allowing the user to push button trim the transmitter output at both zero and span, ideal

for trimming out sensor errors. The transmitters advanced circuitry guaranties high

stability over the wide operating ambient temperature ranges experienced by head

mounted devices.

The 659RTD-1 features an LED which provides visual indication of sensor fault when in

normal operation and is also used to guide the operator through the simple menus during

configuration.

2.0

RECEIVING AND UNPACKING

Please inspect the packaging and instrument thoroughly for any signs of transit damage.

If the instrument has been damaged, please notify your supplier immediately.

3.0

SPECIFICATION @ 20 °C

INPUT

Sensor Type

PT100 100 R @ 0°C 2 or 3 Wire

Sensor Range

(-

200 to +850) ° C (18 to 390) Ω

Sensor Connection

Screw terminal

Minimum span (see note 1)

25 °C

Linearisation

BS EN 60751(IEC 751) standard / JISC1604

Accuracy (see note 2)

±0.1 ° C±0.05% of Reading

Thermal Drift

0.0025 % / °C

Excitation current

< 200 uA

Lead Resistance effect

0.002 ° C/ Ω

Maximum lead Resistance

20 Ω per leg

Note 1

Any span may be selected, full accuracy is only guaranteed

for spans greater than the minimum recommended span.

Note 2

Basic measurement accuracy includes the effects of

calibration, linearisation and repeatability

OUTPUT

Type

Two wire 4 to 20 mA sink

Limits

Low >3.9 mA ; high 21.5 mA

Accuracy

±(mA out / 2000) or ±5 uA which ever greater

Loop Effect

± 0.2 uA / V measured @ 50 Hz 1 V (peak to peak)

Thermal Drift

± 1 uA / °C typical ; ±1.5 uA Max

Max Load

[ (Vsupply

– 10)/21 ] KΩ

GENERAL

Update Time

0.5 Seconds

Response Time

1 Second to reach 90% of final value

Start up time

From power up typically 5 Seconds

Filter Factor

Adaptive

Ambient Temperature

(-40 to 85) °C

Connection

Screw Terminal

Approvals

BS EN 61326 ; 1998

– Electrical equipment for measurement

and control ANNEX A ; ANNEX F

Factory Default

(0 to 100) °C upscale burnout (0.0 °C user trim)

4.0

INSTALLATION AND WIRING

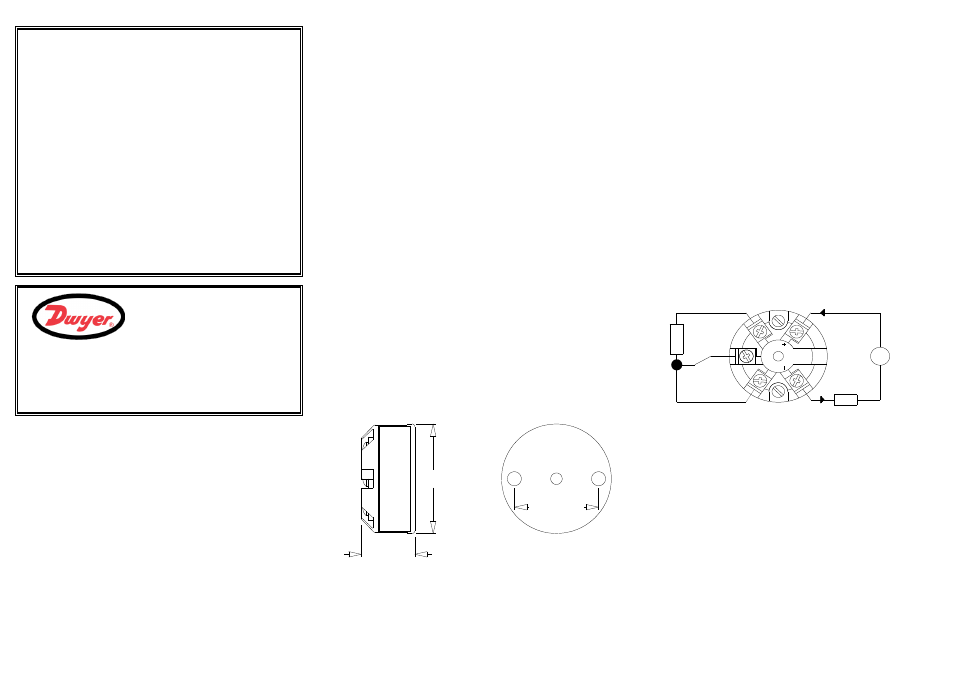

Figure 1

Mounting holes : two holes 5.5 mm diameter, 33 mm centers

Center Hole sensor wire entry : 4 mm

4.1 Mechanical

The transmitter has been specifically designed to fit inside a DIN standard probe head

enclosure, which provides adequate protection from moisture, dust, corrosive

atmosphere etc. All cable entries must be sealed using the correct size gland. Likewise

any probe assembly fitted must be sealed.

Care must be taken when locating the transmitter to ensure the working ambient

temperature range of (-40 to 85) °C is not exceeded. The enclosure has a hole allowing

the sensor wire to enter through the transmitter. This is applicable when the sensor is

mounted directly below the transmitter.

4.2 Electrical

Electrical connections to the transmitter are made to the screw terminal provided on the

top face. The sensor wires must be equal length and type for the lead compensation to

work correctly. The screw terminals allow for wires to enter either inner or outer direction.

The transmitter is protected against reverse connection and over voltage. If no sensor

(input) connection is made the transmitter will go into either up or down scale output

current, depending on configuration.

Figure 2 gives connection details, the output is shown connected to a 24 V supply. The

load symbol represent any other device connected in the loop, such as monitoring

equipment , panel indicators and loop isolators. The load value can range from 0 ohms to

the max loop load for given supply, refer to section 3 “Max load” for more information.

The transmitter conforms with EC directive BS EN 61326 : 1998 when correctly installed

in a termination head providing at least IP20 protection and with sensor wires less than 3

metres. Screened or twisted pair wires are recommended for output wires. Always ensure

the 4 to 20 mA loop is grounded at one point, this would normally be at the monitoring

equipment or loop power supply.

In normal operation the program LED acts as over-range LED.

Figure 2

33.0 mm

CENTERS

Ø 43.0 mm

21.0 mm

SIDE VIEW

BASE VIEW

PUSH BUTTON

PT100

TEMPERATURE

TRANSMITTER

Power

Supply

U

-

+

Load

Pt 100

White

Red

Red

Every effort has been taken to ensure the accuracy of this

specification, however we do not accept responsibility for damage,

injury, loss or expense resulting from errors and omissions, and we

reserve the right of amendment without notice

MODEL 659RTD-1

DWYER INSTRUMENTS, INC.

MICHIGAN CITY, IN 46360 USA