Operational maintenance checks, Maintenance schedule, General inspections – Airedale BluCube 10-48kW User Manual

Page 71: Coil guard cleaning, Electrical inspection, Controls alarm log, Condensing units blucube

Condensing Units

BluCube

™

Condensing Units

71

Installation and Maintenance Manual 7222094: 11/2013

Operational Maintenance Checks

Owners Responsibility

To ensure that the unit can be maintained correctly the following requirements are required.

Maintain a safe working environment around the unit, free from obstructions and debris.

The unit shall follow the following maintenance regime as a minimum.

The equipment contains live electrical and moving parts, ISOLATE prior to maintenance or repair work.

Ensure Lock off procedures is carried out accordingly.

Maintenance Schedule

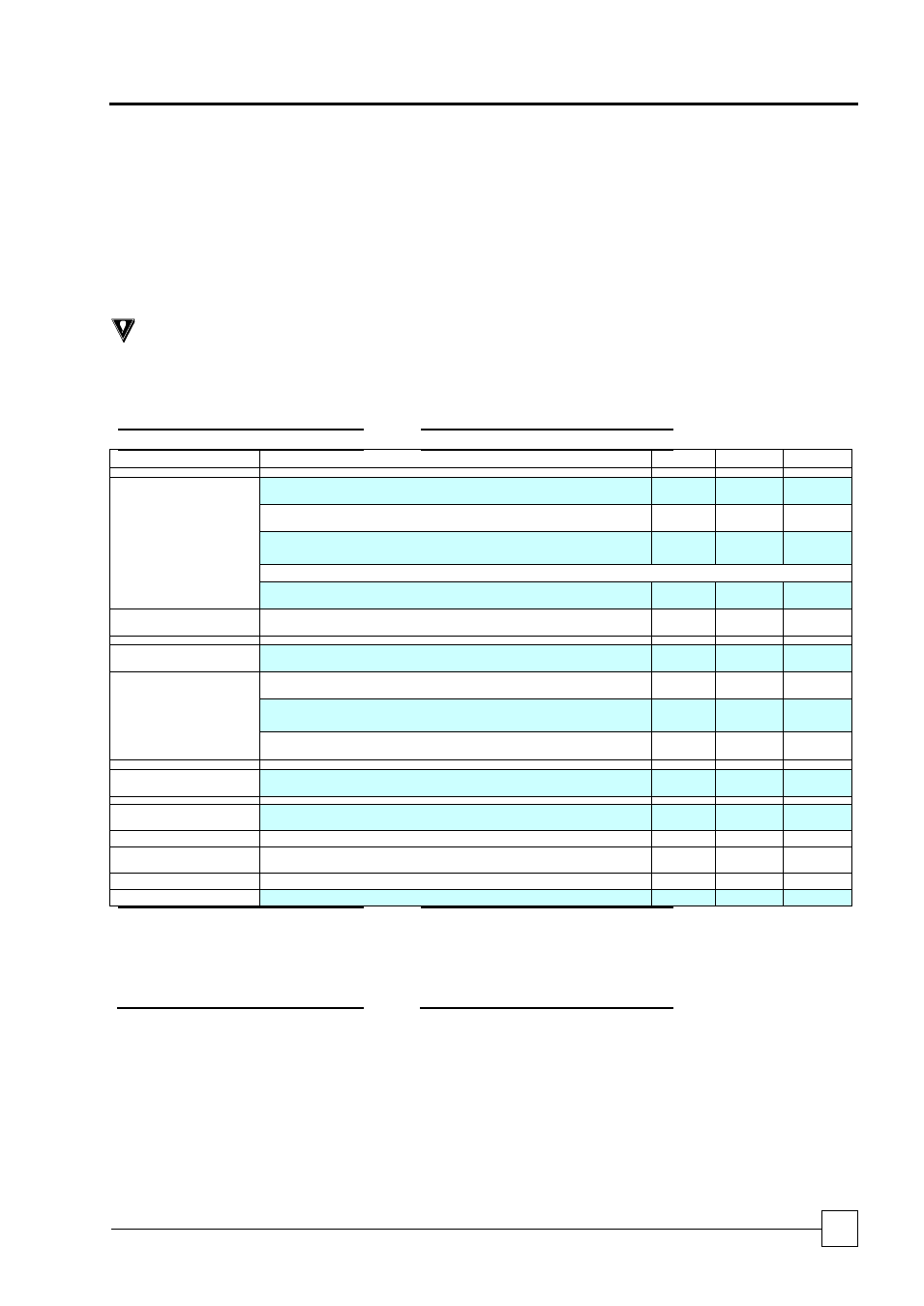

Item

Task

Frequency

Unit Inspection

6 Mths

12 Mths

60 Mths

General Inspections

Check for visible mechanical damage to unit.

Check for cleanliness.

Visually inspect the unit for general wear and tear, treat

metalwork.

Rust should be inhibited, primed and touched up with matching paint.

Check for excess vibration from other rotating equipment.

Coil Guard Cleaning

Ensure that the coil guard is free from debris.

Electrical Inspection

Check main power supply voltages.

Check electrical terminals are tight.

Check that the control panel and fan assembly cables are

securely fastened together.

Check amperages are as per design.

Controls Alarm Log

Check alarm log for any spurious events.

Service tools / Test Equipment

Multimeter

Screwdrivers/ Allen keys

Safety Equipment

Safety Glasses/ Goggles