1 configuration parameters 29, Configuration parameters 29 - 41, Cntr – West Control Solutions KS 92-1 Programmer manual User Manual

Page 29: 1 configuration parameters, Configuration level

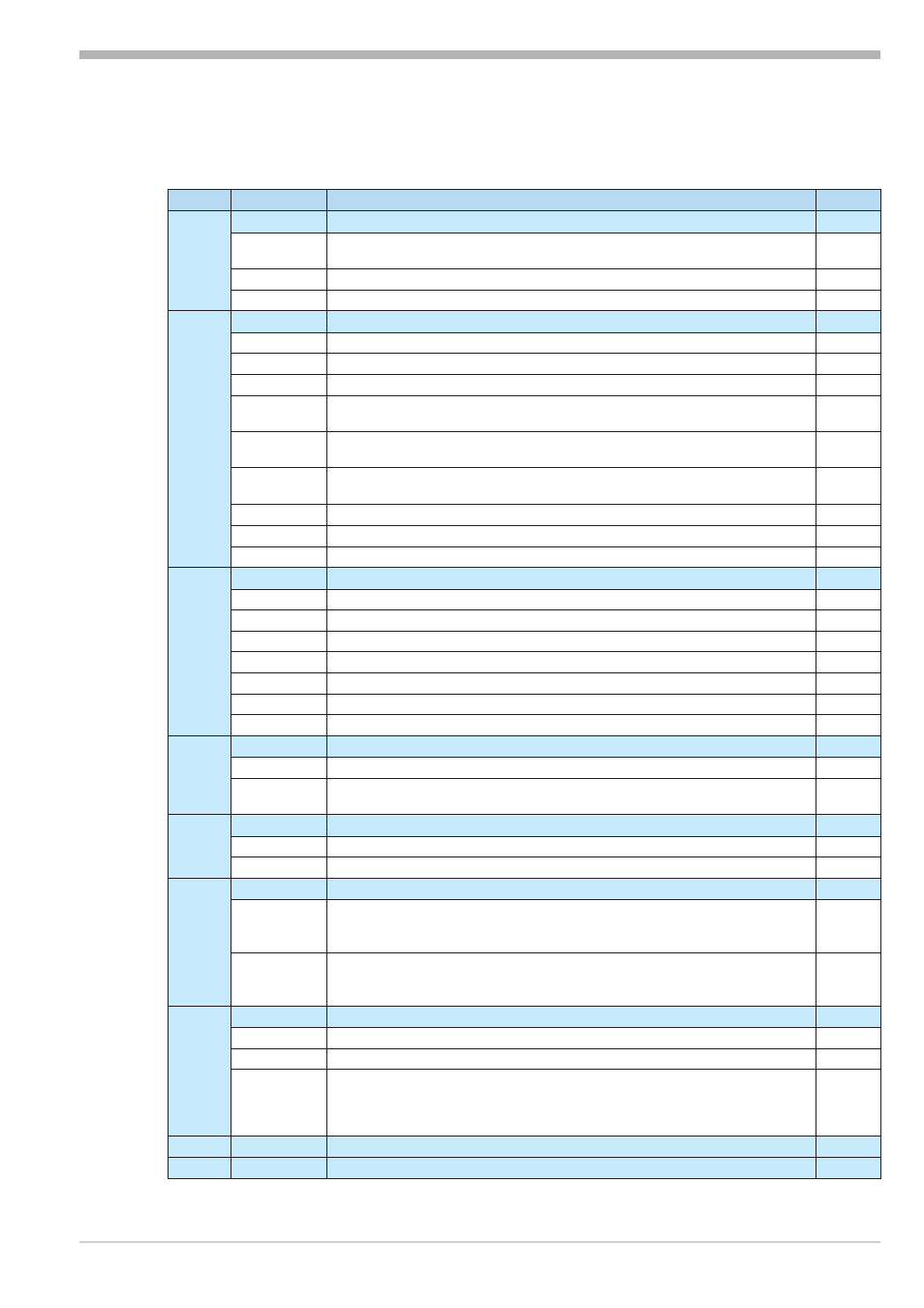

4.1 Configuration parameters

Configuration level

KS 90-1

p / KS 92-1

p

29

Configuration parameters

q

Cntr

Name

Value range Description

Default

SP.Fn

Basic configuration of setpoint processing

0

0

set-point controller can be switched over to external set-point

(->

LOGI/ SP.E)

8

standard controller with external offset (

SP.E)

9

Programmer with external offset (SP.E)

C.tYP

Calculation of the process value

0

0

standard controller (process value = x1)

1

ratio controller (x1/x2)

2

difference (x1 - x2)

3

Maximum value of x1and x2. It is controlled with the bigger value.

At sensor failure it is controlled with the remaining actual value.

4

Minimum value of x1and x2. It is controlled with the smaller value. At

sensor failure it is controlled with the remaining actual value.

5

Mean value (x1, x2). With sensor error, controlling is continued

with the remaining process value.

6

Switchover between x1 and x2 (->

LOGI/ I.ChG)

7

O

2

function with constant sensor temperature

8

O

2

function with measured sensor temperature

C.Fnc

Control behaviour (algorithm)

1

0

on/off controller or signaller with one output

1

PID controller (2-point and continuous)

2

D / Y / Off, or 2-point controller with partial/full load switch-over

3

2 x PID (3-point and continuous)

4

3-point stepping controller

5

3-point stepping controller with position feedback Yp

6

continuous controller with integrated positioner

C.dif

Output action of the PID controller derivative action

0

0

Derivative action acts only on the measured value.

1

Derivative action only acts on the control deviation

(set-point is also differentiated)

mAn

Manual operation permitted

0

0

no

1

yes (r

LOGI / mAn)

C.Act

Method of controller operation

0

0

inverse, e.g. heating

The correcting variable increases with decreasing process value and

decreases with increasing process value.

1

direct, e.g. cooling

The correcting variable increases with increasing process value and

decreases with decreasing process value.

FAIL

Behaviour at sensor break

1

0

controller outputs switched off

1

y = Y2

2

y = mean output. The maximum permissible output can be adjusted

with parameter

Ym.H. To prevent determination of inadmissible va-

lues, mean value formation is only if the control deviation is lower

than parameter

L.Ym.

rnG.L

-1999...9999

X0 (start of control range) 1

-100

rnG.H

-1999...9999

X100 (end of control range) 1

1200