2 configurations 29, Configuration parameters 29 - 37, Cntr – West Control Solutions KS 50-1 User Manual

Page 29: 2 configurations, Configuration level

4.2 Configurations

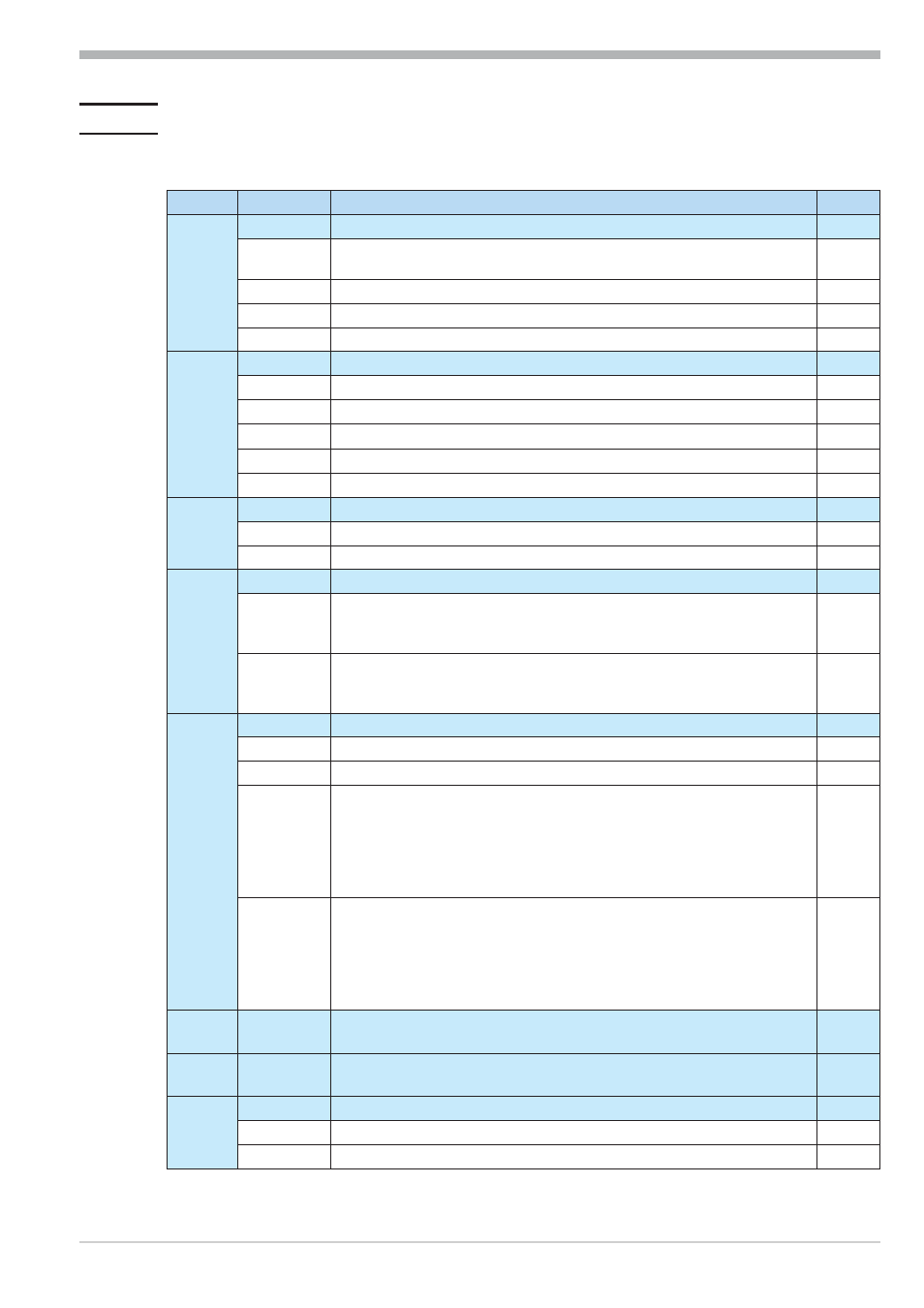

Cntr

Name

Value range Description

Default

SP.Fn

Basic configuration of setpoint processing

0

0

set-point controller can be switched over to external set-point

(->

LOGI/ SP.E)

1

program controller

10

controller with start-up circuit

11

Fixpoint / SP.E-/ SP.2 -controller with start-up circuit

C.Fnc

Control behaviour (algorithm)

1

0

on/off controller or signaller with one output

1

PID controller (2-point and continuous)

2

D / Y / Off, or 2-point controller with partial/full load switch-over

3

2 x PID (3-point and continuous)

4

3-point stepping controller

mAn

Manual operation permitted

0

0

no

1

yes (see also

LOGI/ mAn)

C.Act

Method of controller operation

0

0

inverse, e.g. heating

With decreasing process value, the correcting variable is increased,

with increasing process value, the correcting variable is reduced.

1

direct, e.g. cooling

With increasing process value, the correcting variable is increased,

with decreasing process value, the correcting variable is decreased

FAIL

Behaviour at sensor break

1

0

controller outputs switched off

1

y = Y2

2

y = mean output.

In the event of a failure of the input signal, the mean value of the

correcting variable output last is kept.

The maximum permissible output can be adjusted with parameter

Ym.H.

To prevent determination of inadmissible values, mean value formation is

only if the control deviation is lower than parameter

L.Ym.

3

y = mean output; manual adjustment is possible.

In the event of a failure of the input signal, the mean value of the

correcting variable output last is kept.

The maximum permissible output can be adjusted using parameter

Ym.H . The mean output is measured at intervals of 1 min., when the

control deviation is smaller than parameter

L.Ym.

rnG.L

-1999...9999

X0 (lower limit of control range )

indicates the smallest value to be expected as process value.

0

rnG.H

-1999...9999

X100 (high limit range of control)

indicates the highest value to be expected as process value.

900

SP2C

With active SP.2 no cooling controlling is provided

0

0

standard (cooling permissible with all set-points)

1

no cooling provided with active

SP.2

Configuration level

KS50/52-1

29

Configurations