Warning – Yokogawa YVP20S User Manual

Page 107

10-9

IM 21B04C50-01E

<10. CALIBRATION SERVICES>

Step 2 Select 0% Calibration. Move the valve by entering a value in the Current

Target Position (Change To) text box, and clicking Set, until the valve is in the

desired closed position. The valve can be jogged by selecting the Increment

change amount (0.1 for example, in Figure 10.9) and by clicking the up or

down arrow beside the Change to (%) text box. Click once and wait until the

position value shows the change. Repeat until the valve is at the desired 0%

position. (It is not necessary to click Set, when using the increment arrows.)

Step 3 When the valve is in the closed position click the Apply Calib. Button. A dialog

appears to confirm that you want to apply the calibration. Click Yes.

Step 4 Select Span Calibration. Change the Current Target Position value by entering

a number or by incrementing until the valve is in the desired 100% open

position, using the same procedure as in Step 2 .

Step 5 When the valve is in the open position (refer to the mechanical travel indicator

on the valve), click the Apply Calib. Button. A dialog appears to confirm that

you want to apply the calibration. Click Yes.

Step 6 To apply a correction for non-linearity, select 50% Calibration. Move the valve

until it is at the mechanically indicated 50% position, using the same procedure

as in Step 2 .

0

10

20

30

40

50

60

70

80

90

100

10.00

8.00

6.00

4.00

2.00

0.00

setpoint (%)

Correction Applied (%)

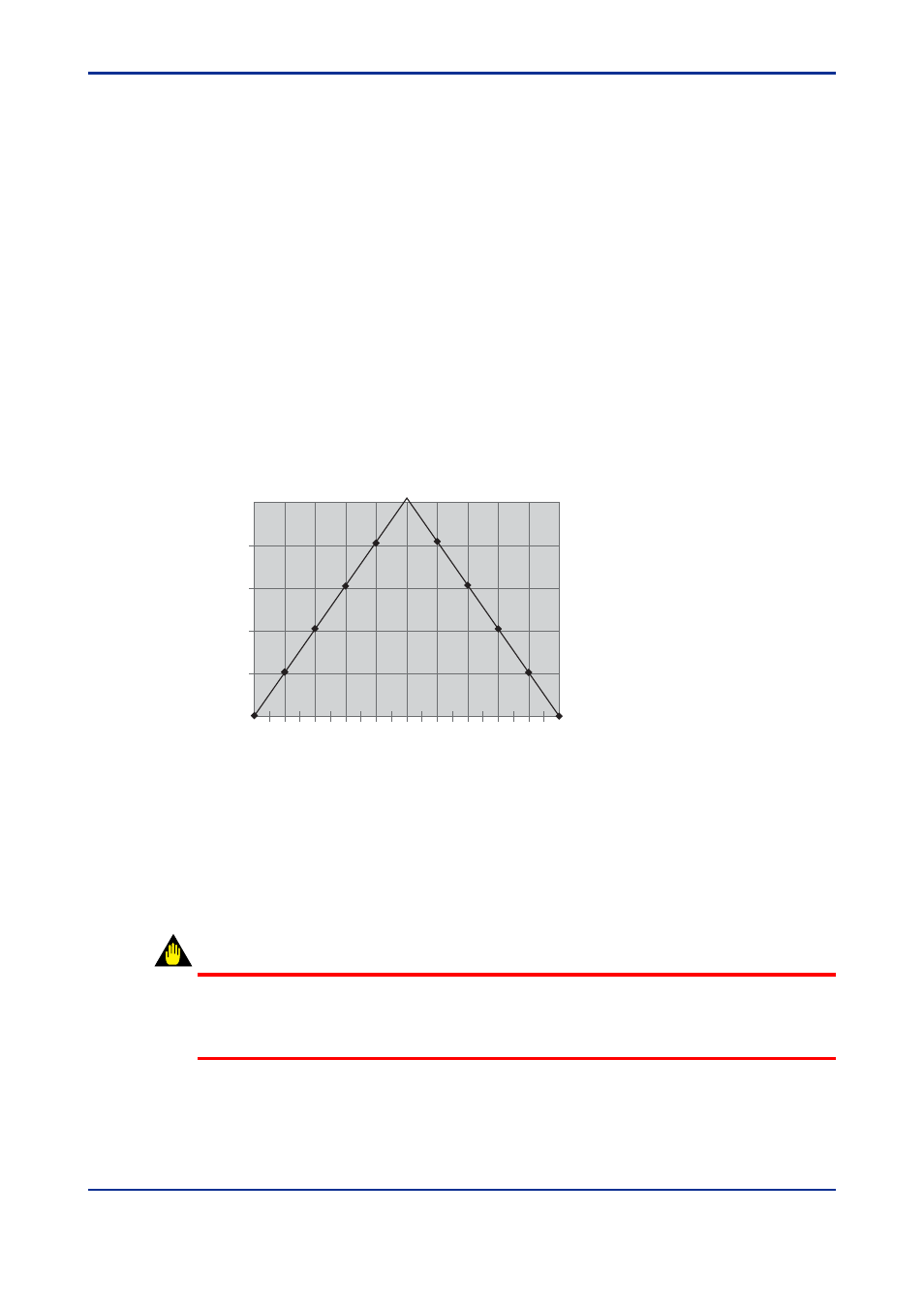

Percent non-linearity error

50% corrected to 60%

F1010

Figure 10.10 Non-linearity Travel Correction

Step 7 When the valve is at the desired 50% position (refer to the mechanical travel

indicator on the valve), click the Apply Calib. Button. A dialog appears to

confirm that you want to apply the calibration. Click Yes. This provides non-

linearity correction with two line segments as shown in Figure 10.10, in which

“55” was entered in the Current Target Position. Note that 55 is an extreme

correction!

WARNING

Applying a correction to the 0% and 100 % position calibration may alter the effect of other

limits and settings. For example, the Tight Shutoff Below and Full Open Above parameter

may need to be re-configured.