Unscheduled maintenance, Inspect/replace condenser filter – ZOLL Thermogard XP IVTM System Operation Manual User Manual

Page 135

Maintenance

5

Unscheduled Maintenance

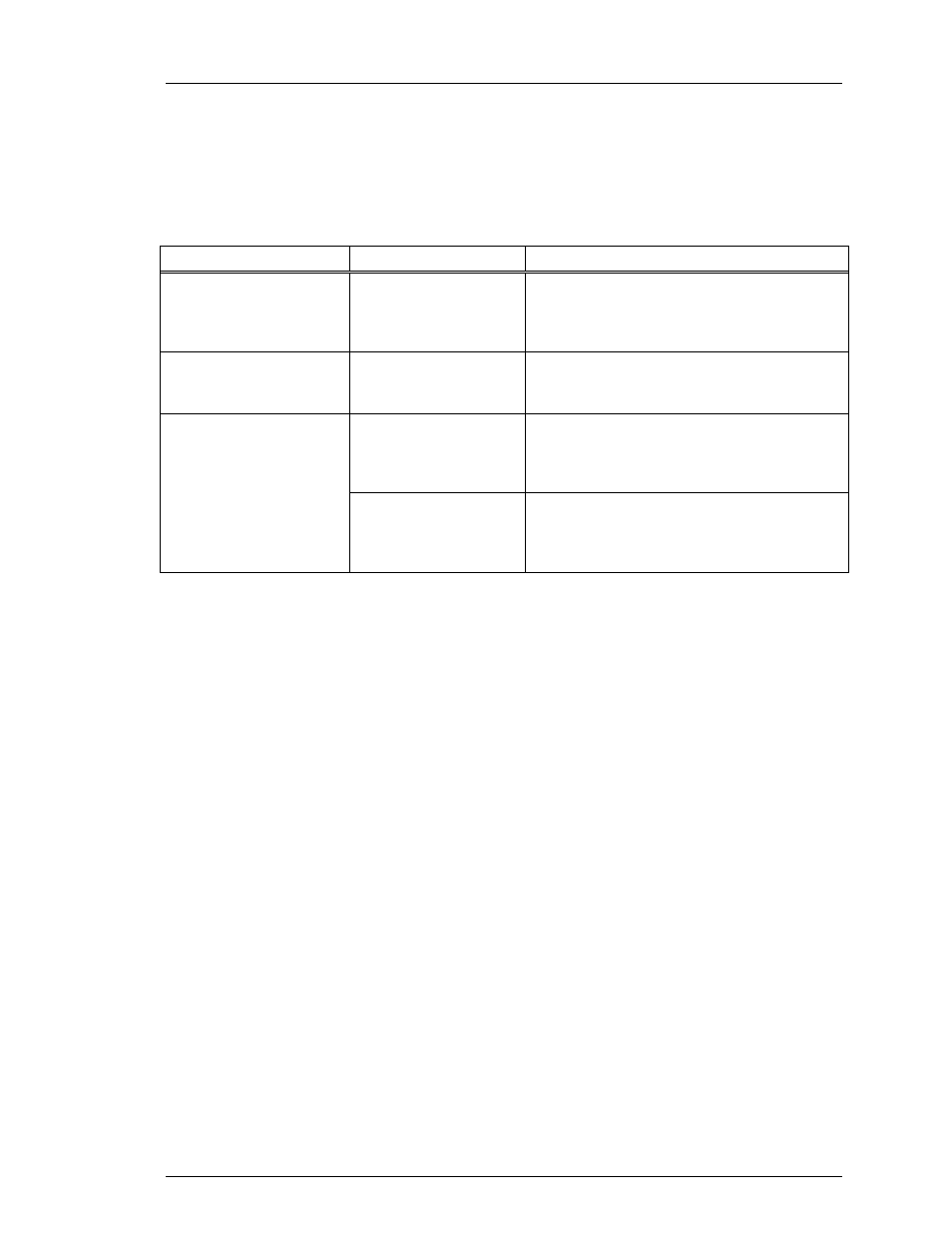

The following table lists unscheduled maintenance tasks for the System. These

tasks should be performed when indicated. Detailed procedures for some tasks

are listed later in this chapter.

Table 8-2. Unscheduled Maintenance.

Item Criteria

Maintenance

Task

System

When deterioration is

evident

Inspect mechanical and electrical

components for wear and loose or

deteriorated parts. Verify continuity of the

electrical ground connection.

System console

When soiled

Clean the exterior of the console (refer to

the “Clean Console and Condensate Pan”

section of this chapter).

Coolant

If contaminated

Drain coolant, clean the coolant well, and

refill with 1:1 mixture of distilled water and

propylene glycol (refer to the “Drain

Coolant” section of this chapter).

If particulate matter is

observed in the

coolant

Drain coolant, clean the coolant well, and

refill with 1:1 mixture of distilled water and

propylene glycol (refer to the “Drain

Coolant” section of this chapter).

Inspect/Replace Condenser Filter

Required Tools and Materials

You will need a Phillips screwdriver, an inspection lamp, and a vacuum cleaner

with a crevice tool to perform these tasks.

Procedure

To inspect and replace the condenser filter, perform these steps in the indicated

order:

1.

Assure that the System has been switched off and the power cord has

been disconnected.

2.

Use a screwdriver to release the screws securing the access door.

Remove the access door from the panel.

3.

Remove and inspect the filter. Replace it if it is clogged with dust.

4.

Use the inspection lamp to inspect the area in and around the

condenser. Look for accumulations of dust and debris.

5.

If necessary, use the vacuum cleaner’s crevice tool to remove dust from

the condenser. Gently pass the crevice tool over all exposed surfaces of

the condenser only. Take care not to bend any of the cooling fins of the

condenser. Never use cleaning fluids or water on the condenser.

6.

When finished, replace the access door and secure the screws.

7.

Inspection and cleaning are complete. The System may be returned to

service.

600479-001 Rev 2 135/147