Scheduled maintenance – ZOLL Thermogard XP IVTM System Operation Manual User Manual

Page 134

Maintenance

4

Scheduled Maintenance

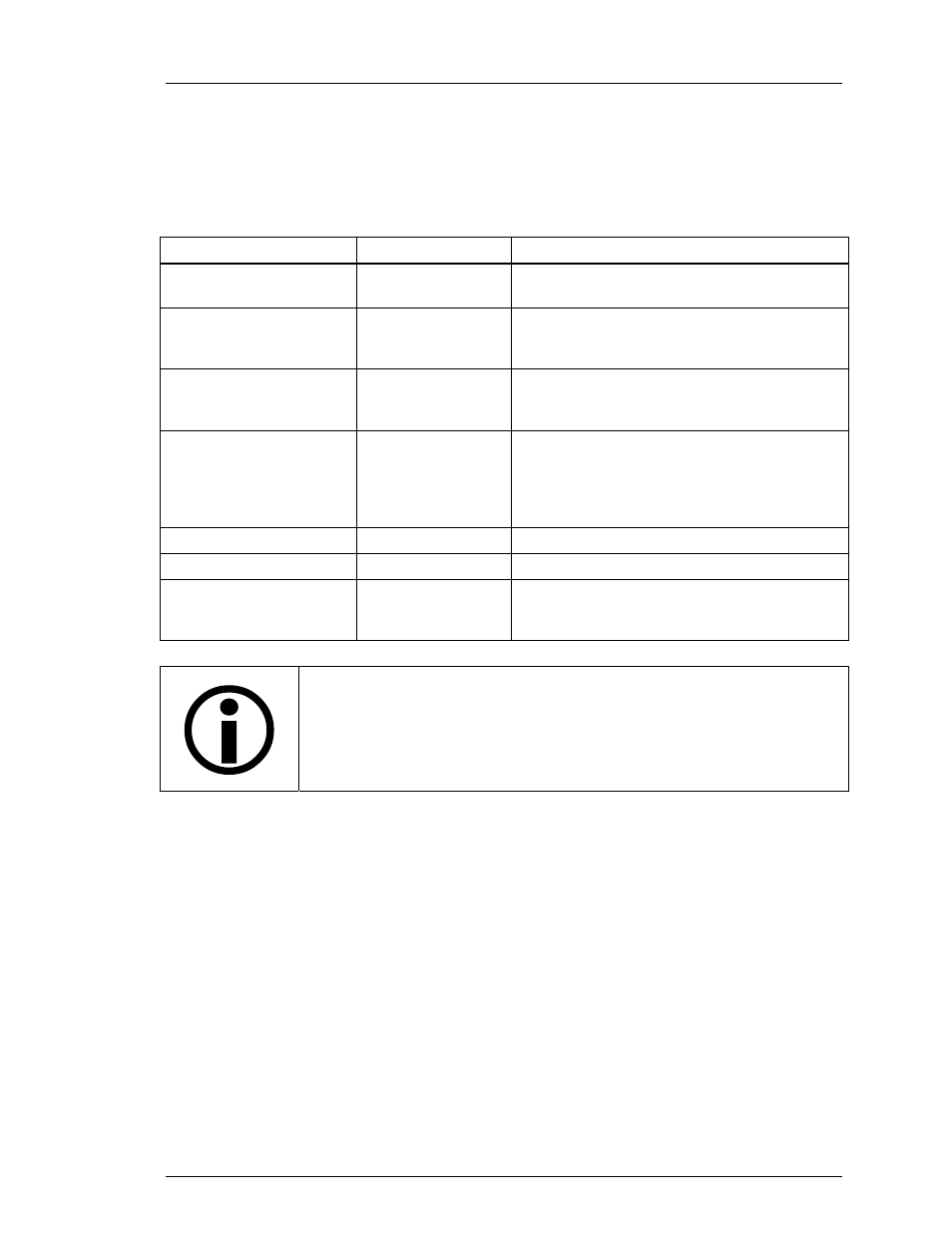

The following table lists scheduled maintenance tasks for the System. Detailed

procedures for some of these tasks are listed later in this chapter.

Table 8-1. Scheduled Maintenance.

Item Frequency

Maintenance

Task

Coolant reservoir

Before each use

Inspect and refill with distilled water to

indicated line if necessary.

Condensate pan

After each use

Inspect. Empty condensate if necessary (refer

to the “Clean Console and Condensate Pan”

section of this chapter).

Refrigeration condenser

filter

Every 6 months

Inspect the filter and replace if necessary

(refer to the “Inspect/Replace Condenser

Filter” section of this chapter).

Roller pump

Monthly

Clean rollers and tubing path with cloth

moistened with water.

Clean rollers and apply light lubri-cating oil if

rollers have been in contact with saline

solution.

Coolant

Annually

Drain and refill with new coolant mixture.

Power cord

Annually

Inspect for wear or damage.

Temperature accuracy

Annually

Perform a temperature accuracy test (refer to

the “Temperature Accuracy Test” section of

this chapter).

NOTE TO INFECTION CONTROL:

50% propylene glycol coolant has been evaluated for antimicrobial

effectiveness and determined not to promote growth of gram negative rods,

gram positive cocci, or yeast microbes. 50% propylene glycol was found to

be comparable to 70% isopropyl alcohol.

600479-001 Rev 2 134/147