7 how to add grease to the ball screw – IAI America NS User Manual

Page 62

48

1

1. Maintenance

11.7 How to Add Grease to the Ball Screw

11.7.1

Applicable Grease

The following lithium grease has been applied prior to shipment.

Kyodo Yushi

Multemp LRL 3

This grease has excellent properties including low heat generation and is suitable for ball screws.

Warning

Never use fluorine grease. If fluorine grease is mixed with lithium grease, lithium grease will lose its

intended lubrication property and the machine may be damaged.

11.7.2

How to Apply Grease

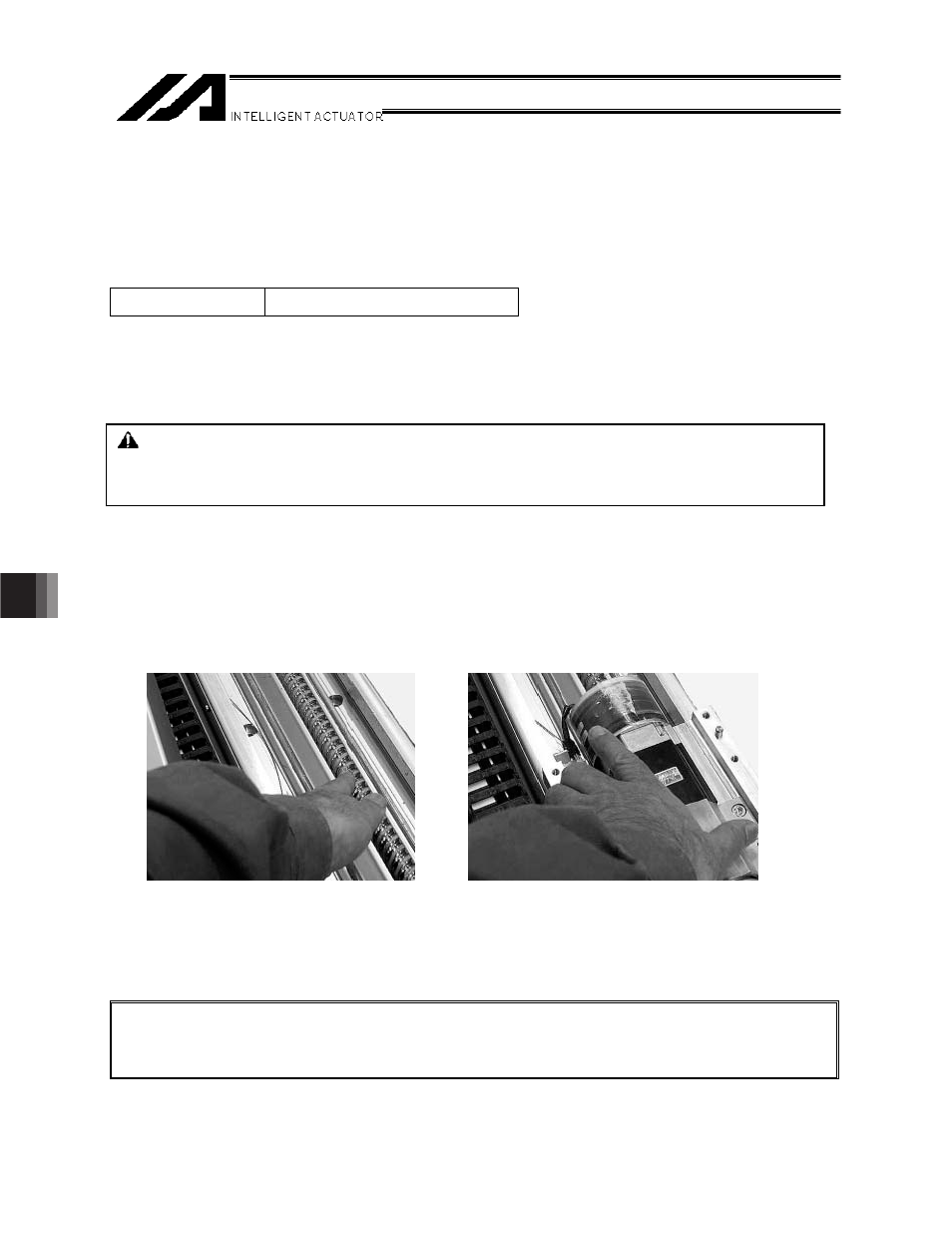

Clean the ball screw before applying grease. Apply grease by hand, and then move the slider back and

forth to let grease spread evenly. Finally, wipe off excess grease that has overflowed from the nut.

Apply grease on the ball screw.

Move the slider. If the actuator is equipped

with a brake, release the brake.

Caution: Adding too much grease may increase the agitation resistance and cause the ball screw

to generate heat easily or the excess grease attached to the ball screw may scatter and

dirty the surrounding area. Be sure to wipe off excess grease.