Installation, 1 installing the actuator – IAI America NS User Manual

Page 44

30

8. Installation

8.

Installation

How to install the actuator is explained based on a single-axis configuration.

8.1

Installing the Actuator

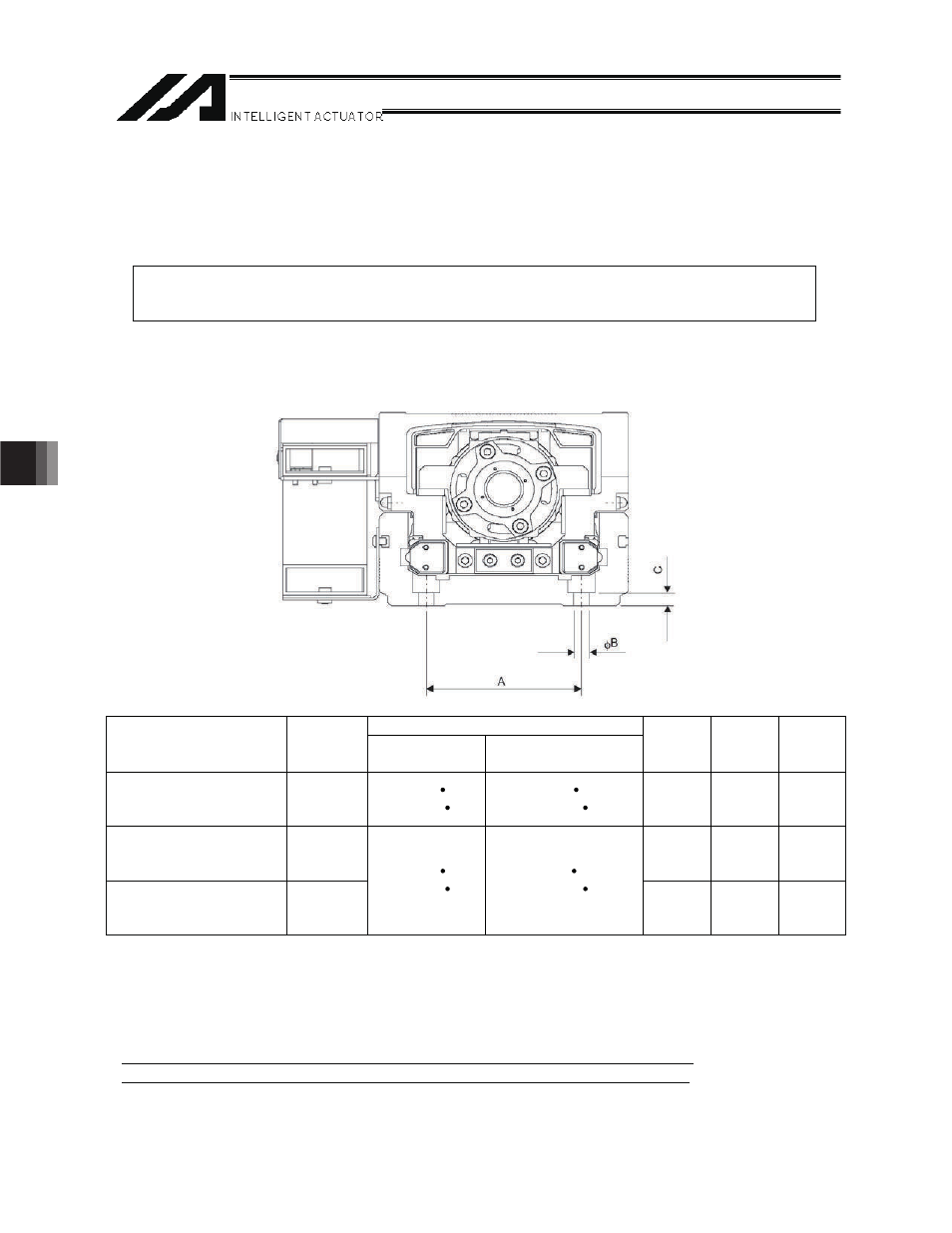

The surface on which to install the actuator shall be a machined surface or a flat surface having

equivalent accuracy.

x Mounting holes are provided in the actuator base, so use these holes to install the actuator. Use M8

bolts conforming to strength category 10.9 or above, together with the dedicated washers that came with

the actuator (to prevent buckling).

Tightening torque

Applicable

bolt

Bolt bearing

surface is steel

Bolt bearing surface

is aluminum

Dimension

A

Dimension

B

Dimension

C

Small type

SXMS, SXMM, SZMS,

SZMM

M6

12.3 N m

(1.26 kgf m)

5.4 N m

(0.55 kgf m)

50

7

6

Medium type

MXMS, MXMM,

MXMXS, MZMS, MZMM

5

9

0

7

8

M

Large type

LXMS, LXMM, LXMXS,

LZMS, LZMM

M8

31.3 N m

(3.19 kgf m)

14 N m

(1.43 kgf m)

90

9

8

About tightening screws

x Use hexagonal socket head bolts as the male threads with which to install the actuator base.

x Use of high-strength bolts conforming to ISO 10.9 or above is recommended.

x The effective engagement length between the bolt and female thread shall be at least the value

specified below:

When the male thread is made of steel

o Same as the nominal diameter

When the male thread is made of aluminum

o 1.8 times of nominal diameter

x If the bolt bearing surface is made of aluminum, also use a dedicated washer for high-strength bolt. (If

the bolt is applied without an appropriate washer, the bearing surface may buckle.)