IAI America RCA2-SA6R User Manual

Page 84

76

13. Maintenance Inspection

Tension gauge

Tension

SA3R: 1.5

r 0.1 kgf

Other than SA3R: 2.5

r 0.1 kgf

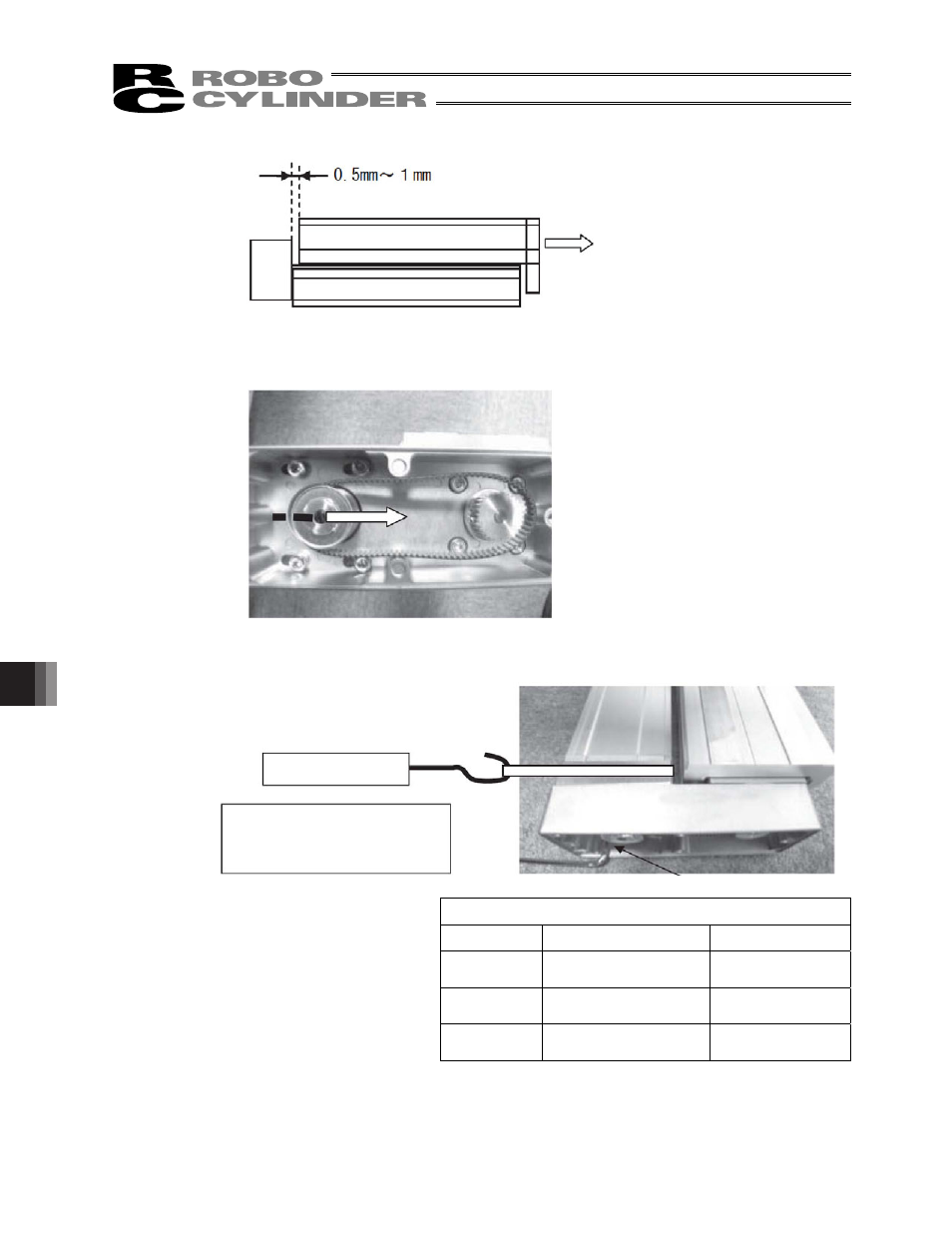

[6] Move the slider or table by 0.5 to 1 mm from the mechanical end on the home side.

[7] Move the motor unit in the direction of the arrow shown below, and then install the belt.

Align the motor unit with the countermark on the actuator.

When replacing the belt, install the replacement belt.

[8] Pass around the base of the motor unit a strong string (or long tie band) that has been looped, and

pull the loop with a tension gauge. When the specified tension is achieved, tighten the tension

adjustment bolts uniformly.

Tension adjustment bolt

Model

Nominal thread size

Tightening torque

SA3R M2.6

0.46 N

xm

(0.047 kgf

xm)

SA4R M3

0.83 N

xm

(0.085 kgf

xm)

SA5R/SA6R

M4

1.76 N

xm

(0.18 kgf

xm)