8 belt – IAI America RCA2-SA6R User Manual

Page 75

67

13. Maintenance Inspection

Tension

SA3R: 1.5

r 0.1 kgf

Other than SA3R: 2.5

r 0.1 kgf

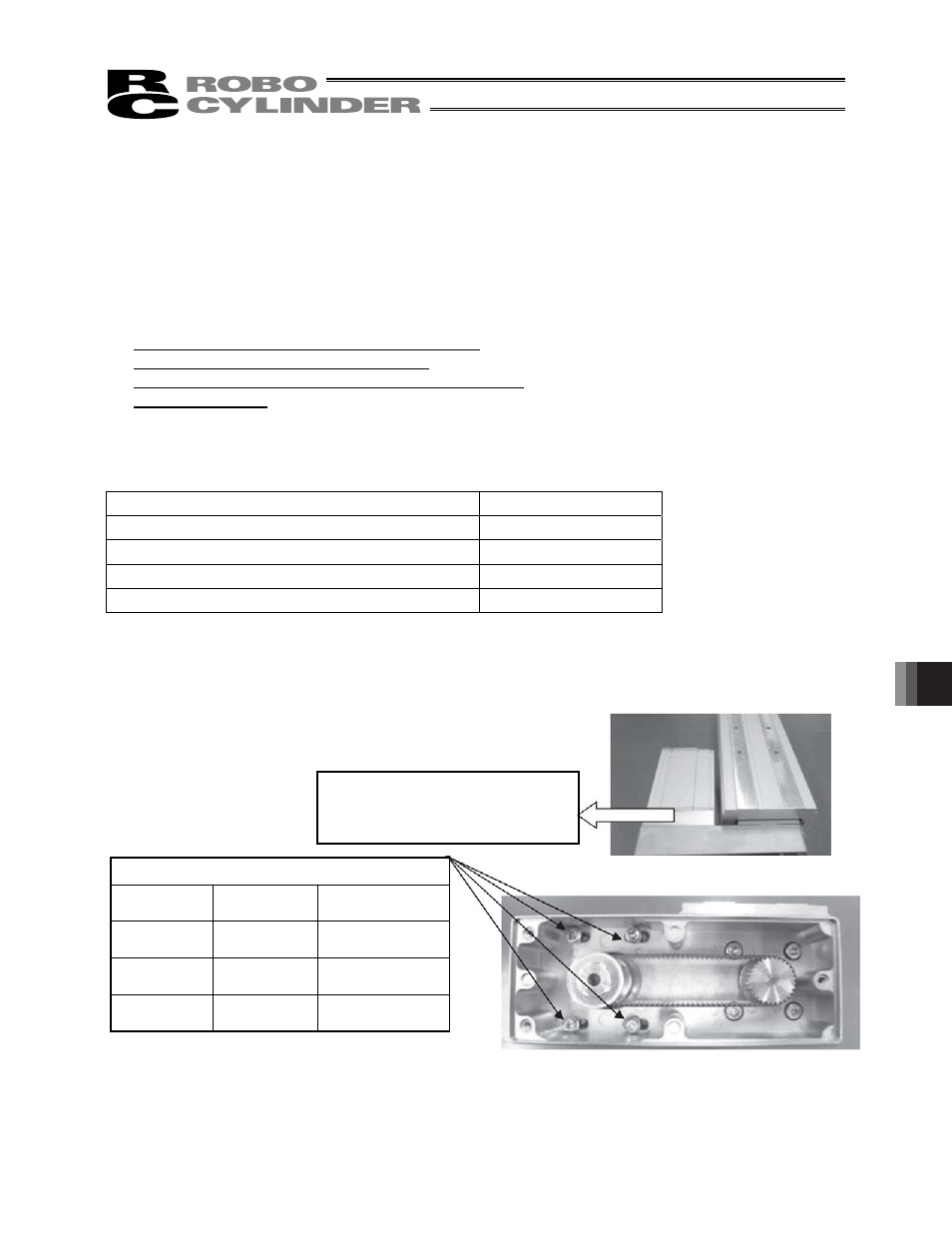

Tension adjustment bolt

Model

Nominal

thread size

Tightening

torque

SA3R M2.6

0.46 N-m

(0.047 kgf-m)

SA4R M3

0.83 N-m

(0.085 kgf-m)

SA5R/SA6R M4

1.76 N-m

(0.18 kgf-m)

13.8 Belt

13.8.1 Inspection of belt

When inspecting the belt, remove the pulley cover and check the belt visually.

Although the durability of the belt is affected significantly by the operating conditions, generally a belt has

a flex line of several million times.

As a reference for determining when to actually replace the belt, replace the belt if any of the following

conditions is found:

x Significant wear of the teeth or end face of the belt

x Swelling of the belt due to attached oil, etc.

x Cracking or other damage of the teeth or back of the belt

x Breaking of the belt

13.8.2 Applicable belt

Manufacturer: Bando Chemical Industries, Ltd.

Belt model (type)

Model

40S2M138R, 4-mm wide (clean rubber type)

SA3R

60S2M152R, 6-mm wide (clean rubber type)

SA4R

60S2M180R, 6-mm wide (clean rubber type)

SA5R

60S2M180R, 6-mm wide (clean rubber type)

SA6R

13.8.3 Adjustment of belt tension

Remove the pulley cover, loosen the tension adjustment bolts (4 locations), and shift the motor as shown

below to tension the belt. When finished, tighten the tension adjustment bolts.