Maintenance inspection, 1 inspection items and schedu, 2 external visual inspection – IAI America RCA2-SA6R User Manual

Page 69

61

13. Maintenance Inspection

13. Maintenance Inspection

13.1 Inspection Items and Schedule

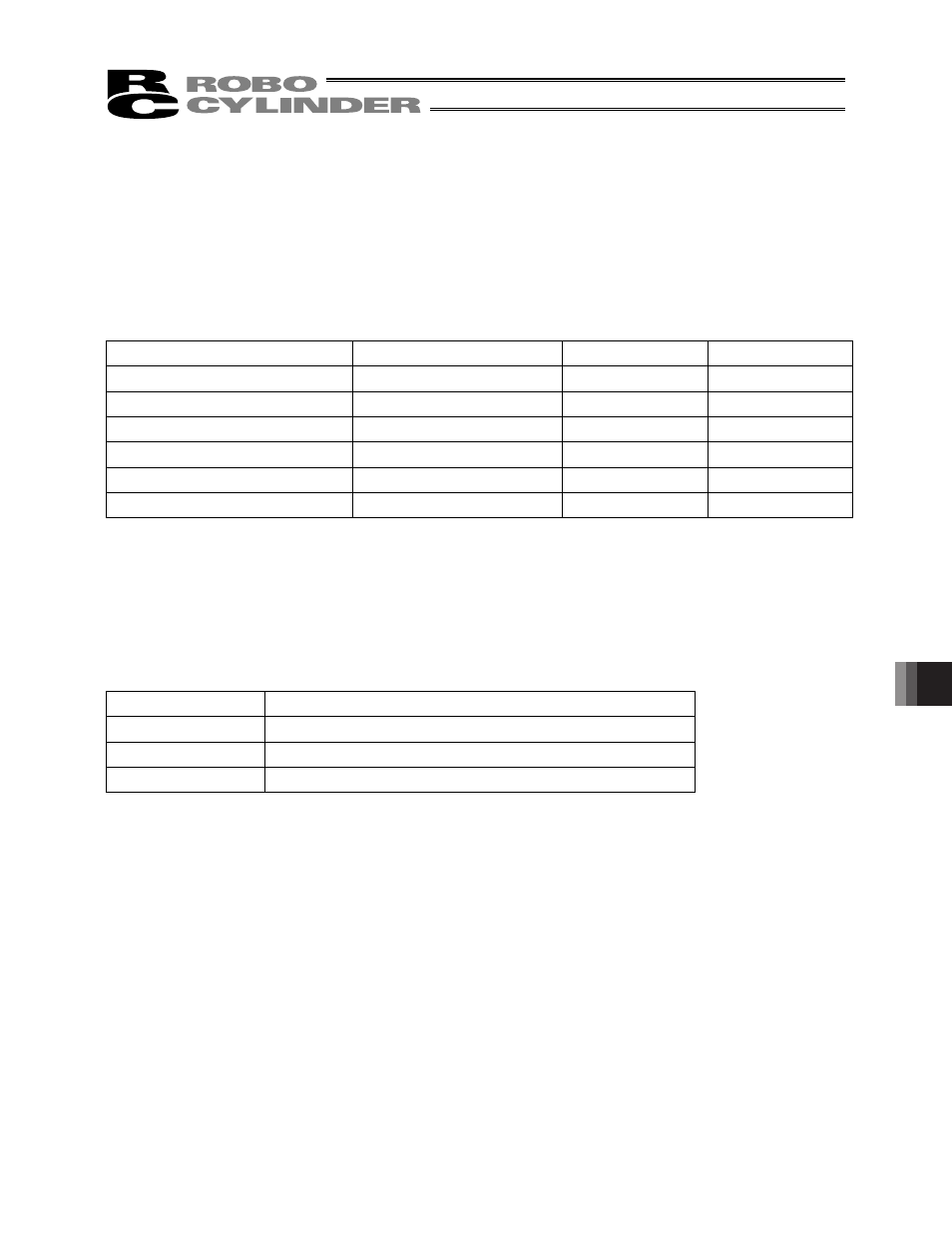

Follow the maintenance inspection schedule below.

It is assumed that the equipment is operating 8 hours per day.

If the equipment is running continuously night and day or otherwise running at a high operating rate,

inspect more often as needed.

External visual inspection

Internal inspection Greasing*2

Start of work inspection

{

1-month inspection

{

6-month inspection

{

{

12-month inspection

{

{

{

Every 6 months thereafter

{

Every 12 months thereafter

{

{

{

*1 If grease is found degraded as a result of interior check, add grease

*2 Grease film may run out if the actuator is moved back and forth continuously over a distance of 30 mm or less. As a guide,

perform a back-and-forth operation five times or so over a distance of 50 mm or more after a back-and-forth operation over such

short distance has been repeated 5,000 to 10,000 times. This will restore oil film.

13.2 External Visual Inspection

An external visual inspection should check the following things.

Main unit

Loose actuator mounting bolts, other loose items, buildup

Cables Scratches,

proper connections

Stainless sheet

Scratches, slacked

Overall

Irregular noise, vibration

y If the stainless sheet is slacked, make adjustment to remove the slack as necessary.

y As a rule of thumb, the stainless sheet should last for about 5000 km of slider motion. However, under

certain conditions, the stainless sheet may need to be replaced earlier.

Generally, replacing the stainless sheet will require that you bring the unit to our plant or have one of

our technicians come to your plant to perform the replacement.

y If the actuator is installed vertically, certain conditions may cause grease to drip from the guide. Please

ensure that proper cleaning is performed and grease is replenished.