Securitron SAM2-24 User Manual

Page 9

PN# 500-10450

Page 9

Rev. B, 02/12

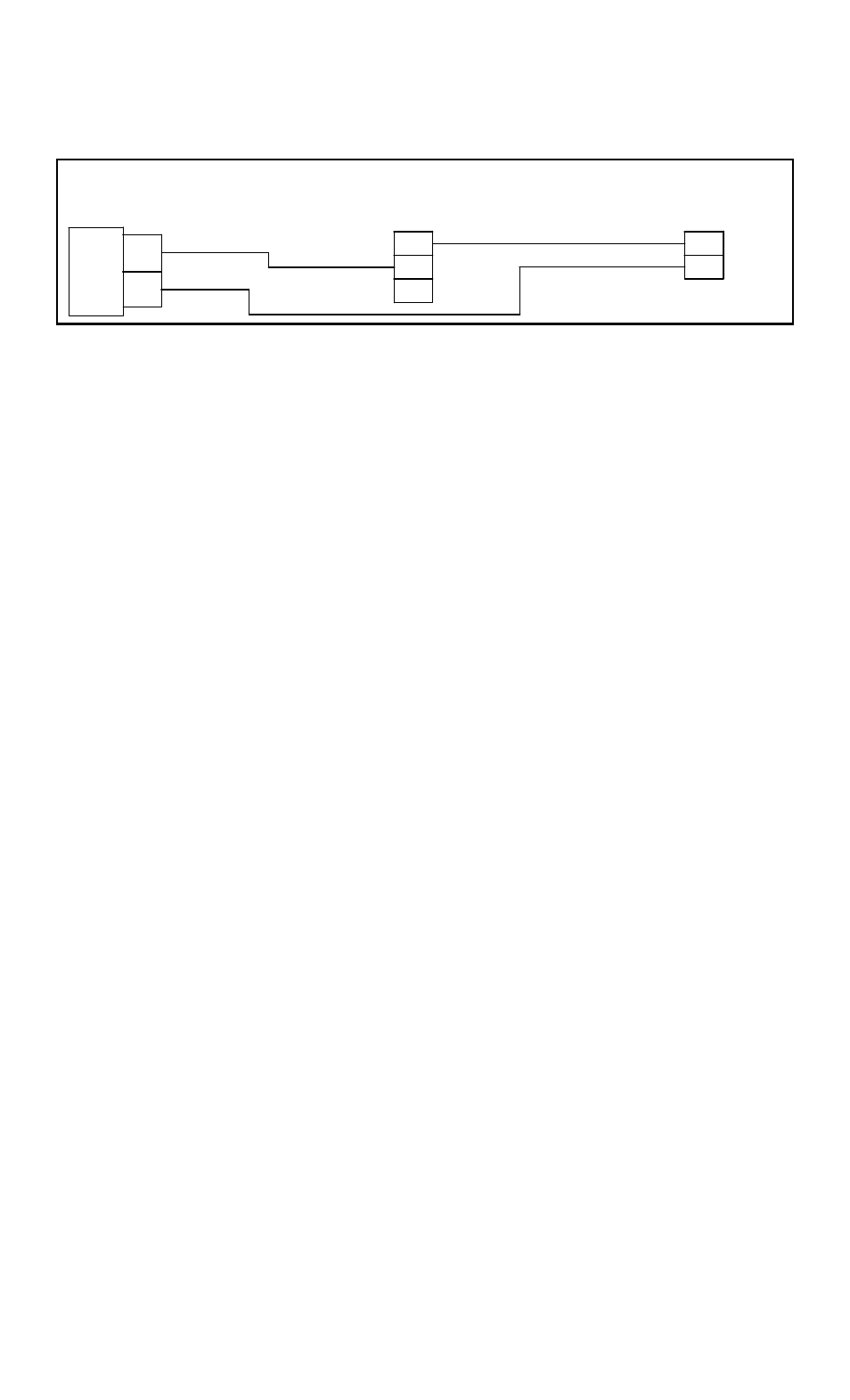

6.4 Electrical Wiring

The following diagram, Figure 13, represents the proper electrical wiring connections required

for the SAM2-24 Magnalock.

_

+

NC

+

C

NO

RED

_

BLK

SAM2-24

2-WIRE

MAGNALOCK

ACCESS

CONTROL

DEVICE

DC

POWER

SUPPLY

120

VAC

INPUT

24

VDC

OUTPUT

Figure 13

6.5 Emergency Release

Magnalocks are often wired into a system for quick release in case of emergency. Manual

switching or automatic triggering from a fire alarm system is practical. It is the user's

responsibility to correctly hookup the Magnalock according to the instructions. It is

recommended to use a switch or relay to perform break of power. Securitron power supplies

have terminals for the interconnection of such emergency release switches.

THE END USER AND INSTALLER ARE LIABLE FOR ALL FIRE AND BUILDING CODE

COMPLIANCE.

7 MAGNALOCK MAINTENANCE

7.1 Visual Inspection

Check the strike assembly for proper gap, suspension and free movement. Tighten strike

adjustment screws as required.

Check for build-up of debris on the Magnalock and strike armature. Clean as required.

Check for rust on the Magnalock and strike assembly. Clean as required.

7.2 Cleaning Methods

Cleaning once a year is recommended.

Clean every six months where minor rusting occurs.

Clean every three months if rust conditions are severe.

Use a plastic dishwashing scrub pad to aid in the removal of rust.

DO NOT USE PETROLEUM BASED PRODUCTS FOR CLEANING

DO NOT USE STEEL WOOL BASED SCRUB PAD OR SANDPAPER

7.2.1 Indoor Applications

Apply rubbing alcohol onto a clean cloth and thoroughly wipe down the Magnalock and

strike plate armature.

7.2.2 Outdoor Applications

Apply a silicone based cleaner/lubricant onto a clean cloth and thoroughly wipe down

Magnalock and strike plate armature.

Example: Super Lube® Aerosol with SYNCOLON® (PTFE)

Part No.: 31040 ~ 6oz. / 31110 ~ 11 oz. / 32015 ~ 14 oz.

Phone: (631) 567-5300 / Website: www.super-lube.com